Struktursimulation Endlosfaserverbunde

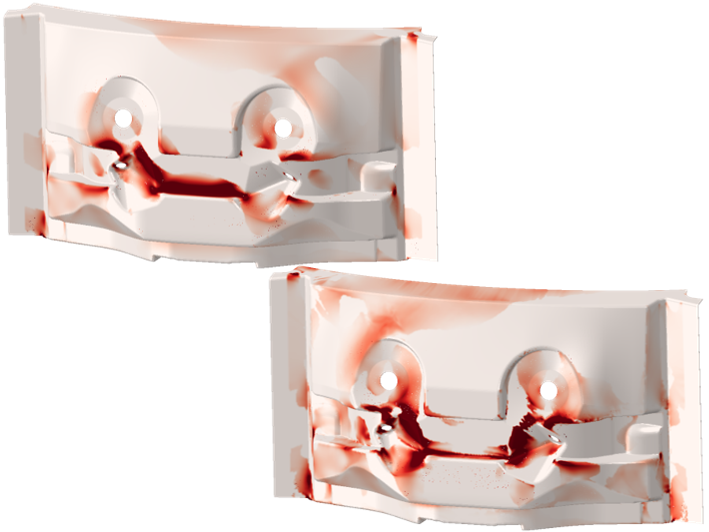

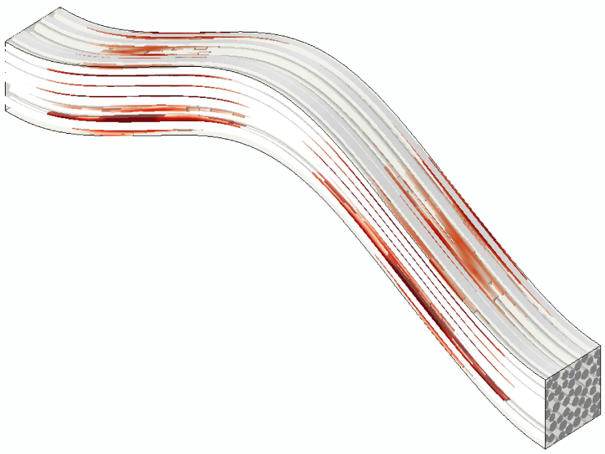

The deformation and damage behavior of continuous-fiber composite components is largely determined by the structure of the reinforcing fibers. Fiber orientation, fiber volume content, and local effects such as waviness and gapping can vary significantly as a result of the forming process. To consider this in the prediction of the structural mechanical behavior, we incorporate the process information provided by the CAE chain in the structural simulation. For this purpose, we develop material models that capture the nonlinear deformation behavior and the damage evolution in a failure mode-specific manner (fiber fracture, matrix fracture, delamination) as a function of the local fiber structure.

Research focus

- Virtual validation of composite components

- Consideration of manufacturing effects

- Nonlinear material modeling

- Failure analysis, damage evolution

- Dynamic analysis: vibration, damping, impact

- Multiscale simulation

Research projects |

Contact

|

Selected publications in the research field

Frölich, F.; Di Nardo, M. E.; Krauß, C.; Heuer, A.; Liebig, W. V.; Wittemann, F.; Carlone, P.; Kärger, L.

2025. Additive Manufacturing, 113, Article no: 105023. doi:10.1016/j.addma.2025.105023

Esse, D.; Sick, G.; Henning, F.; Fiedler, B.; Liebig, W. V.

2025. Polymer Testing, 151, 108960. doi:10.1016/j.polymertesting.2025.108960

Schelleis, C.; Scheuring, B. M.; Schreyer, L.; Liebig, W. V.; Hrymak, A.; Kärger, L.; Weidenmann, K. A.; Henning, F.

2025. Journal of Thermoplastic Composite Materials, 38 (8), 2922–2944. doi:10.1177/08927057251344252

Refat, M.; Maertens, R.; Weiss, P.; Henning, F.; Schulze, V.; Liebig, W. V.

2025. Polymers, 17 (5), Art.-Nr.: 651. doi:10.3390/polym17050651

Esse, D.; Scheuring, B.; Henning, F.; Liebig, W. V.

2025. Polymer Testing, 146, 108747. doi:10.1016/j.polymertesting.2025.108747

Li, Z.; Jackstadt, A.; Zhang, J.; Liebig, W. V.; Kärger, L.

2025. Polymer Composites, 46 (1), 817–831. doi:10.1002/pc.29028

Jackstadt, A.

2025. doi:10.5445/KSP/1000172235

Jackstadt, A.

2024, May 23. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000170788

Jackstadt, A.; Liebig, W. V.; Weidenmann, K. A.; Kärger, L.

2024. Materials & Design, 241, Article no: 112882. doi:10.1016/j.matdes.2024.112882

Galkin, S.

2022, April 14. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000144697

Meyer, N.; Wagemann, E. L.; Jackstadt, A.; Seifried, R.

2022. Computational Particle Mechanics, 9 (6), 1293–1308. doi:10.1007/s40571-022-00471-z

Li, Z.; Zhang, J.; Jackstadt, A.; Kärger, L.

2022. Composite structures, 287, Art.Nr.: 115340. doi:10.1016/j.compstruct.2022.115340

Jackstadt, A.; Liebig, W. V.; Kärger, L.

2022. International journal of mechanical sciences, 216 (216), Art.Nr.: 106964. doi:10.1016/j.ijmecsci.2021.106964

Jackstadt, A.; Frölich, F.; Weidenmann, K.; Kärger, L.

2021. Proceedings in applied mathematics and mechanics, 21 (1), e202100098. doi:10.1002/pamm.202100098

Sessner, V.; Liebig, W. V.; Jackstadt, A.; Schmid, D.; Ehrig, T.; Holeczek, K.; Gräbner, N.; Kostka, P.; Wagner, U. von; Weidenmann, K. A.; Kärger, L.

2021. Applied composite materials, 28 (5), 1715–1746. doi:10.1007/s10443-021-09934-7

Jackstadt, A.; Kärger, L.

2021. Proceedings in applied mathematics and mechanics, 20 (1), Art.-Nr.: e202000234. doi:10.1002/pamm.202000234

Kunze, E.; Galkin, S.; Böhm, R.; Gude, M.; Kärger, L.

2020. Materials, 13 (13), Art. Nr.: 2959. doi:10.3390/ma13132959

Schöttl, L.; Kolb, P.; Liebig, W. V.; Weidenmann, K. A.; Inal, K.; Elsner, P.

2020. Composites communications, 21, Art. Nr.: 100384. doi:10.1016/j.coco.2020.100384

Kärger, L.; Galkin, S.; Dörr, D.; Poppe, C.

2020. Procedia manufacturing, 47, 140–147. doi:10.1016/j.promfg.2020.04.155

Jackstadt, A.; Liebig, W. V.; Sessner, V.; Weidenmann, K. A.; Kärger, L.

2019. Proceedings in applied mathematics and mechanics, 19 (1), e201900048. doi:10.1002/pamm.201900048

Galkin, S.; Kunze, E.; Kärger, L.; Böhm, R.; Gude, M.

2019. Journal of composites science, 3 (1), Article: 19. doi:10.3390/jcs3010019

Liebig, W. V.; Jackstadt, A.; Sessner, V.; Weidenmann, K. A.; Kärger, L.

2019. Composites science and technology, 180, 101–110. doi:10.1016/j.compscitech.2019.04.019

Sessner, V.; Jackstadt, A.; Liebig, W.; Kärger, L.; Weidenmann, K.

2019. Journal of composites science, 3 (1), 3. doi:10.3390/jcs3010003

Meeuw, H.; Körbelin, J.; Bernstorff, D. von; Augustin, T.; Liebig, W. V.; Fiedler, B.

2018. Materialia, 1, 185–197. doi:10.1016/j.mtla.2018.06.002

Liebig, W. V.; Sessner, V.; Weidenmann, K. A.; Kärger, L.

2018. Composite Structures, 202, 1109–1113. doi:10.1016/j.compstruct.2018.05.051

Leopold, C.; Harder, S.; Philipkowski, T.; Liebig, W. V.; Fiedler, B.

2018. Materials, 10 (12), Art. Nr.: 2517. doi:10.3390/ma11122517

Kärger, L.; Galkin, S.; Zimmerling, C.; Dörr, D.; Linden, J.; Oeckerath, A.; Wolf, K.

2018. Composite structures, 192, 143–152. doi:10.1016/j.compstruct.2018.02.041

Galkin, S.; Schirmaier, F. J.; Kärger, L.

2018. Journal of composite materials, 52 (4), 475–485. doi:10.1177/0021998317709332

Leopold, C.; Schütt, M.; Liebig, W. V.; Philipkowski, T.; Kürten, J.; Schulte, K.; Fiedler, B.

2017. Materials, 10 (9), Art.Nr.: 1039. doi:10.3390/ma10091039

Leopold, C.; Augustin, T.; Schwebler, T.; Lehmann, J.; Liebig, W. V.; Fiedler, B.

2017. Journal of colloid and interface science, 506, 620–632. doi:10.1016/j.jcis.2017.07.085

Botzkowski, T.; Galkin, S.; Wagner, S.; Sikora, S. P.; Kärger, L.

2016. Composite structures, 141, 194–202. doi:10.1016/j.compstruct.2016.01.057

Kärger, L.; Bernath, A.; Fritz, F.; Galkin, S.; Magagnato, D.; Oeckerath, A.; Schön, A.; Henning, F.

2015. Composite structures, 132, 350–358. doi:10.1016/j.compstruct.2015.05.047