Whitsun Excursion 2025

This year's Whitsun excursion began on Tuesday afternoon with a visit to Eckerle Technologies GmbH in Malsch. After a friendly welcome, we were first given a company presentation focussing on the development and use of internal gear pumps. In an exciting presentation, we learnt about their diverse market applications and modern development methods such as CFD, CAD and FEM. We then visited the test field with NVH test benches and test systems for hydraulic pumps. A subsequent tour of the production and assembly areas rounded off the visit and provided valuable insights into the industrial production of hydraulic components.

On Wednesday morning, the programme included a visit to RAUCH Landmaschinenfabrik GmbH in Rheinmünster. The long-established company presented modern fertiliser technologies under the motto ‘Save fertiliser - increase efficiency’. An introduction to the product range was followed by an informative tour of the factory, during which we were able to experience the production of innovative agricultural machinery at close quarters. In the most modern test hall for agricultural machinery in Europe, we were also given a practical demonstration of how individual components work, before the visit ended with an open discussion.

In the afternoon of the same day, we visited the Unimog Museum in Gaggenau. In addition to a historical overview of the development of the Unimog, we were given the opportunity to take a seat in a Unimog ourselves and experience it up close during a ride in the field - an interactive highlight that many of us will remember for a long time.

The excursion concluded on Thursday with a visit to Joseph Vögele AG in Ludwigshafen, a Wirtgen Group company. After a comprehensive tour of the plant - from raw material processing to individual part production and final assembly - we were given in-depth insights into the various types of road pavers during a technical presentation. In addition, innovative assistance systems and digital solutions for improving construction quality and efficiency were presented, with which Vögele is playing a key role in shaping the development of modern road construction technologies.

We would like to thank everyone involved for planning, financing and organising this year's Whitsun excursion. Special thanks go to the companies for the interesting insights, specialist presentations and guided tours.

Excursion to John Deere

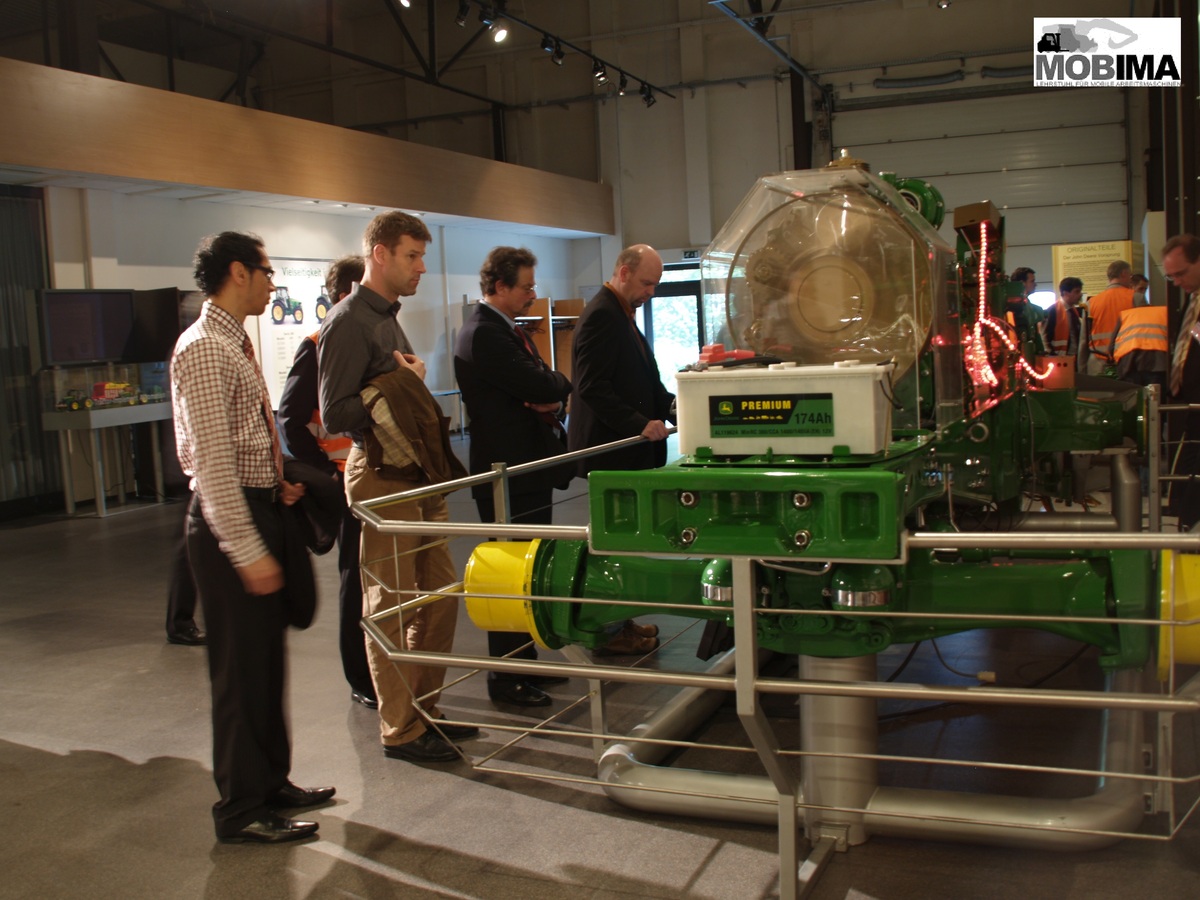

On 30.04.2025, the Institute for Mobile Machinery (Mobima) of the Karlsruhe Institute of Technology organized an exciting excursion for students as part of the tractor lecture. The destination was the John Deere plant in Mannheim, the company's largest tractor plant outside America. The participants had the opportunity to visit the modern production facility, including the company's own transmission production. They also visited the plant's own museum, where the historical development of tractors was impressively presented. The excursion provided the students with valuable insights into industrial production and technological innovation at John Deere.

Anniversary of the symposium "Hybrid and energy-efficient drives for mobile machinery"

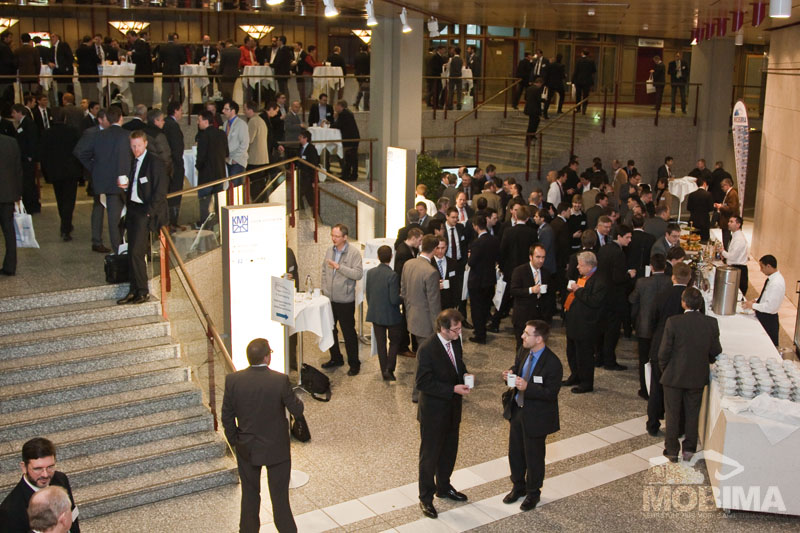

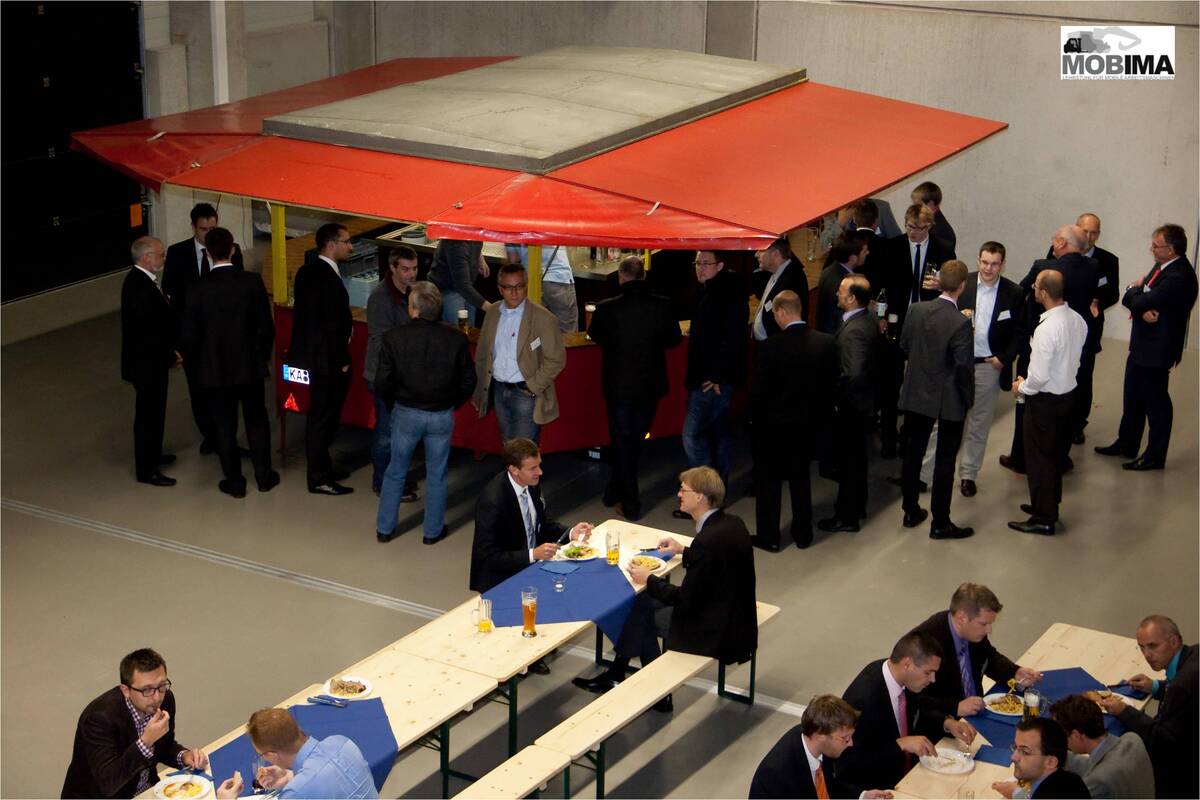

More than 120 participants attended the 10th edition of the "Hybrid and energy-efficient drives for mobile machinery" symposium in Karlsruhe on February 19. The conference was organized by the Karlsruhe Institute of Technology (KIT). The conference was organized by the Institute's Mobile Machinery Division (Mobima) with the support of FVA GmbH.

The specialist audience from science and industry kicked off the conference the evening before with an evening event at KIT's Campus East. In a convivial setting, insights into the research work of Mobima and a tour of the all-wheel drive acoustic roller test bench were provided. The evening before the hybrid conference was also the conclusion of the 8th symposium "MOBILE MACHINES - Safety and Driver Assistance for Work Machines", which offered plenty of potential for interesting discussions. The evening event was supported by the sponsorship of Bosch Rexroth.

On 19.02, the Hybrid Conference 2025 was opened by Institute Director Prof. Dr.-Ing. Marcus Geimer. Dr. Ing. Karsten Wilbrand inspired the audience with his keynote speech on the decarbonization of mobile machinery.

This was followed by interesting presentations in various sessions with the main topics of "Reducing emissions and increasing efficiency", "Electrification", "Emission-free vehicle drives" and "Battery storage". The 11 technical presentations were accompanied by exciting discussions. Concepts for reducing emissions for driving mobile machinery and alternatives to fossil diesel as an energy source were the overarching themes of the presentations. Different and needs-based solutions were presented and discussed.

The breaks between the presentations invited participants to discuss detailed questions and visit the accompanying trade exhibition. InMarch, Hydac, M&M software and MOBIMA e.V. provided information about their current work and developments.

We would like to express our sincere thanks to the speakers and the advisory board, whose input and expertise made a significant contribution to the success of the conference. We would also like to thank the participants, sponsors and exhibitors and look forward to welcoming you back to Karlsruhe in 2027.

The conference proceedings published for the event will be made available free of charge in digital form via the KIT library. You can download the conference proceedings here.

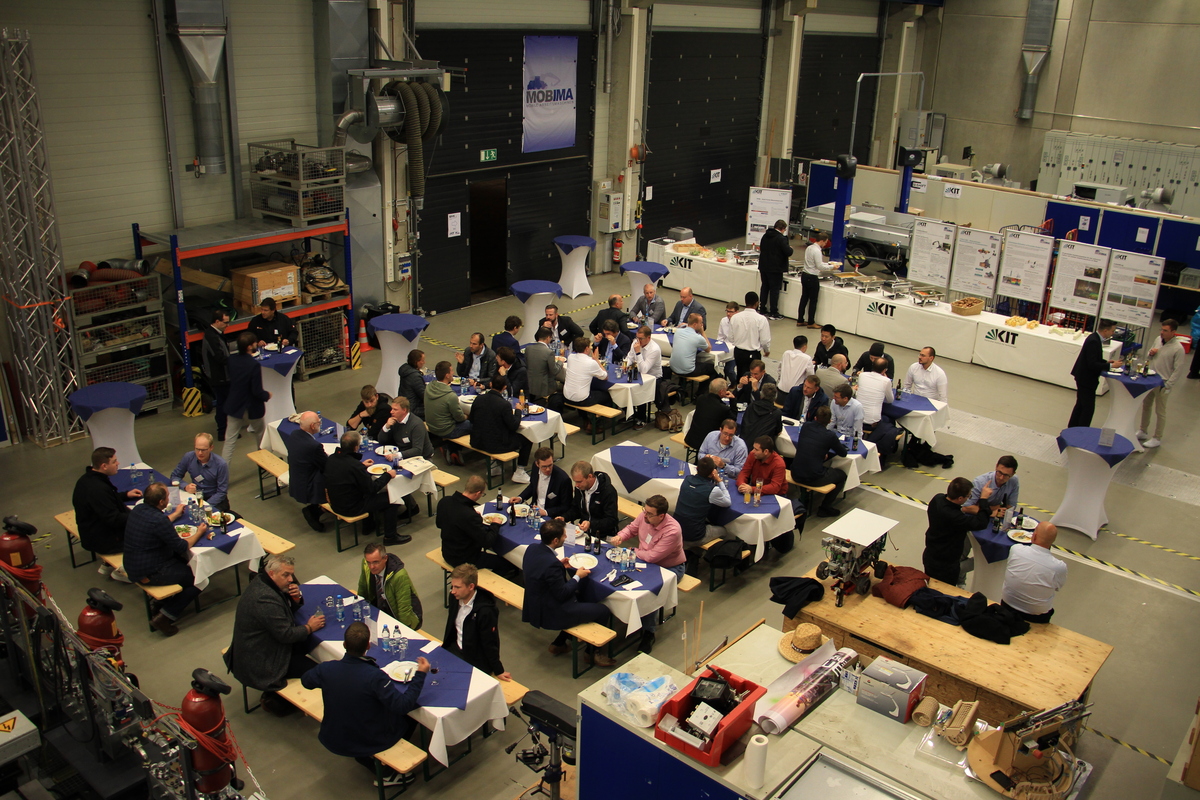

Successful continuation of the symposium MOBILE MACHINES - Safety and driver assistance for work machines!

After a four-year break, the 8th MOBILE MACHINES conference took place in Karlsruhe on February 18, 2025. Organized by the Karlsruhe Institute of Technology (KIT) and hosted by the Mobile Machinery Division (Mobima) with the support of FVA GmbH, the conference offered a platform for interdisciplinary exchange between research and industry.

The conference was opened by Institute Director Prof. Dr. Marcus Geimer. This was followed by an inspiring keynote speech by Prof. Dr. Katharina Schmitz on the topic of "Smart Mobile Machines: Data collectors and data users".

Over the course of the day, 11 specialist lectures were presented to around 80 participants. The presentations were divided into different sessions focusing on the following topics: "Data management", "Sensor technology and environment recognition", "Assistance and AI" and "Autonomous driving". The presentations and subsequent discussions offered insights into current developments and practical solutions for making work machines safer, more autonomous and more efficient.

In addition to the presentations, the accompanying trade exhibition provided an ideal opportunity for networking. The companies Hydac, InMach, M&M Software and MOBIMA e.V. presented their latest developments and current work.

The conference concluded with an evening event at the KIT's Campus East. The presentations were reflected upon and discussed in a convivial setting. Insights into the research work of Mobima and a tour of the all-wheel acoustic roller test bench were also provided. The MOBILE MACHINES evening event was also the prelude to the "10th Symposium on Hybrid and Energy-Efficient Drives for Mobile Machinery". The get-together offered plenty of potential for interesting discussions. The evening event was supported by the sponsorship of Bosch Rexroth.

Special thanks go to the speakers and the advisory board, whose expertise and contributions made a significant contribution to the success of the conference. We would also like to thank the participants, exhibitors and sponsors - we look forward to welcoming you back to Karlsruhe!

The conference proceedings published for the event will be made available free of charge in digital form via the KIT library. You can download the conference proceedings here.

Guest visit to China

In the block lecture "Fluid Power Systems and Dynamics" from October 14 to 18, Marcus Geimer offered interested students at Tongji University in Shanghai the opportunity to take an in-depth look at hydraulics. The first part of the course covered the basics, starting with the elementary laws of hydraulics and moving on to various components and complex circuits. The second part then dealt with the dynamics of hydraulics with a focus on the various natural frequencies in order to provide an outlook towards control. In addition to the lecture, there was still enough time to discuss control topics in detail with colleagues on site.

Many thanks to Tongji University and Professor Yongming Bian for this unique opportunity. We look forward to further academic exchanges.

13th Colloquium on Mobile Hydraulics

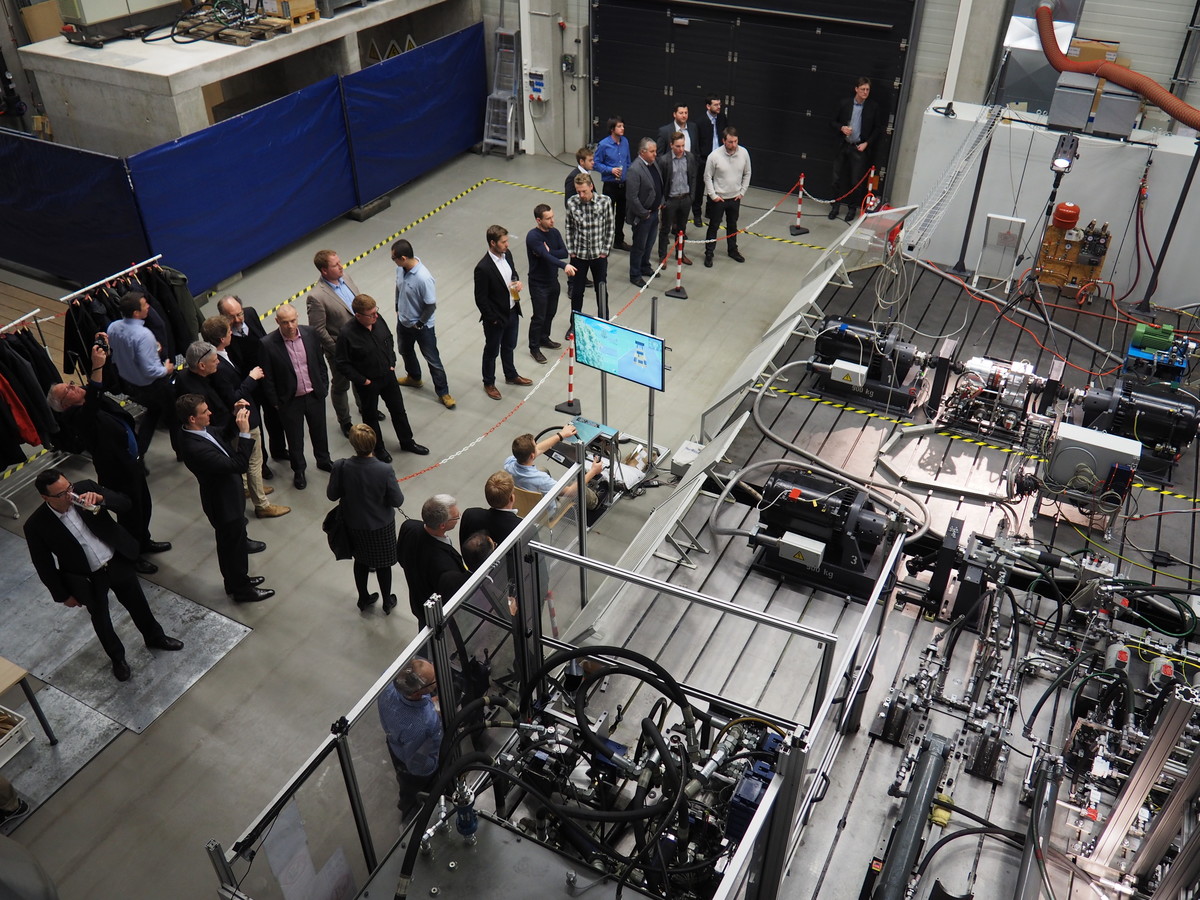

The 72 participants realized that the 13th edition of the Mobile Hydraulics Colloquium, which took place in Karlsruhe this year (08.10. - 09.10.), is a very special conference when Prof. Dr.-Ing. Geimer opened the conference in the converted all-wheel acoustic roller test bench on KIT's Campus East. An inspiring keynote speech by Mr. Knobloch on the topic of "Electrification and the energy transition without hydraulics - it doesn't work" was followed by nine exciting specialist presentations from industry and science.

In addition to the unique location, the special attraction of the event is that there is a corresponding demonstrator for each presentation. This gave participants the opportunity to see the innovative concepts and solutions in the field of mobile hydraulics presented in the lectures in action and discuss them on the exhibit.

Thanks to a great group of speakers and participants, there were countless stimulating discussions and plenty of valuable insights into the various areas of mobile hydraulics. We hope you also enjoyed our event and that you not only gained new insights, but also made new contacts.

A big thank you goes to everyone who contributed to the success of the event - be it through your sponsorship (InMach GmbH, Bosch Rexroht AG, John Deere GmbH & Ko. KG), your contributions and demonstrators, your participation or your commitment before and during the event. Your support has made the 13th Mobile Hydraulics Colloquium possible!

We are already looking forward to our upcoming events (Hybrid Conference, Mobile Machines) and hope to welcome many of you again!

Doctoral candidate meeting 2024

On July 11-12, 2024, the doctoral student meeting "Agricultural Engineering" took place at the Technical University of Munich in Freising. The participants traveled from various institutes in different cities, including Munich, Braunschweig, Dresden, Hohenheim, Osnabrück, Cologne and Karlsruhe. The journey from Karlsruhe was made by train. The meeting began on Thursday morning with a welcome from Prof. Bernhardt, followed by a get-together and a round of introductions. After lunch at "LACANTO", there was a campus tour through Weihenstephan, followed by a "World Café" including an afternoon snack. The day ended with a snack in the beer garden of the Hofbrauhauskeller Freising. The second day began with a visit to the Hüll Hop Research Center, including a guided tour with a focus on "Experiments on energy saving during drying and conditioning" and insights into the development of new hop varieties. After lunch at the "Landgasthof Siebler z'Egg", the Josef Wimmer farm gave the participants a guided tour of the first and only agri-PV system in a hop garden. In the late afternoon, there was a guided tour of the "Gräfliches Hofbrauhaus Freising" with a focus on quality management and production, including a small snack. The evening offered the opportunity for a cozy finale and a farewell in Freising. The meeting was a complete success and gave the participants the opportunity to get to know each other better and make contacts for future exchanges.

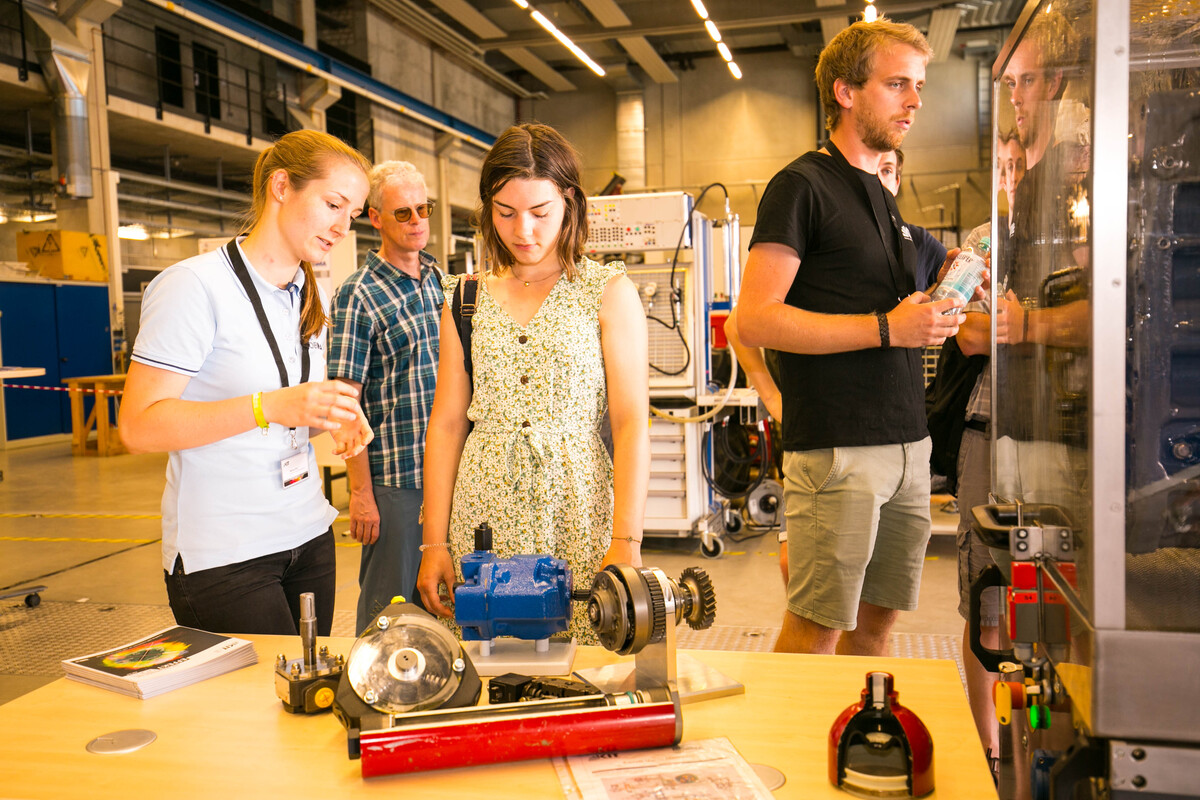

Campus Day 2024

On 8.6.24, KIT hosted a campus day where pupils could take a look at the various degree programs and students and graduates could ask questions. Mobima was also represented with a stand. There was a tractor and the corresponding gearbox demonstrator on display. Questions were asked about the mechanical engineering and mechatronics courses, the content of the institute's section and the exhibits. The gearbox demonstrator in particular aroused interest, as visitors were able to operate it themselves and see how their control inputs continuously changed the output speed at a constant input speed. We hope that all visitors enjoyed it and that we were able to inspire some students to study mechanical engineering, mechatronics and Mobima.

Whitsun excursion 2024

This year's Whitsun excursion began on Tuesday morning with a joint trip to Groß-Umstadt to the DLG Test Center for Technology and Farm Inputs. On site, we were first welcomed with lunch and greeted personally by the managing director. We were then given an insight into the fields of activity in a presentation. Agricultural and work machinery can be tested and certified at the site in accordance with DLG standards. During the subsequent tour of the company halls, we were shown the test benches for vehicle cabins and the test track, among other things. One highlight was the DLG's own roller test bench, on which all agricultural and work machinery can be tested for their specific characteristics. The tour was followed by a drive to the hotel near Aschaffenburg, where we ended the evening together with dinner and drinks.

After the short drive from the hotel to Linde Material Handling in Aschaffenburg, we received a warm welcome on site. After a brief review of the company's history and a presentation of the product range, we had the opportunity to inspect some forklift variants in the customer showroom and try them out for ourselves. We were then given a guided tour of the factory premises. From the production of the lift masts and the welding of the superstructure and substructure to the assembly of all the individual components into the finished forklift truck, we were given many interesting insights. Among other things, the anecdotes about the company's history told by a long-standing employee were fascinating. After the tour, we made our way back home towards Karlsruhe. There we had dinner together and recharged our batteries for the next day.

From Karlsruhe, we drove together to Kraichtal to the Argo-Hytos company. There we were given a brief introduction to the company and then an exciting technical presentation on the hydraulic tank systems developed by Argo-Hytos. This was followed by a guided tour of the plant. After lunch, we were given an insight into the Applications Engineering International division and learned how important it is to always consider the overall system and not just individual components. Later in the afternoon, we drove to an external site, an agricultural business. There, we were introduced to a project in which a field sprayer was enhanced with a system developed in-house so that the distance between nozzles and crops always remains the same, even on uneven terrain. The problem was first explained to us and before the implemented solution was presented, we had time to work out potential solutions ourselves in small groups. Seeing the developed system live in action was particularly impressive. Afterwards, Argo-Hytos invited us to a nearby winery for a wine tasting followed by dinner, where we rounded off the day together before heading back to Karlsruhe.

We would like to thank everyone involved for planning, financing and supporting this year's Whitsun excursion. Special thanks go to the companies for the interesting insights, specialist presentations and guided tours.

Excursion John Deere

On April 17, 2024, nine students and two supervisors from the Institute of Mobile Machinery visited the John Deere plant in Mannheim. The excursion has been offered for several years as part of the "Tractors" lecture.

During a factory tour, the students were given an insight into the production of modern tractors, from parts production to final assembly. The John Deere plant in Mannheim is one of the company's largest production sites outside the USA. With over 2,000 employees, agricultural machinery is manufactured here for the global market. The excursion promoted professional exchange and the students' interest in their subject area.

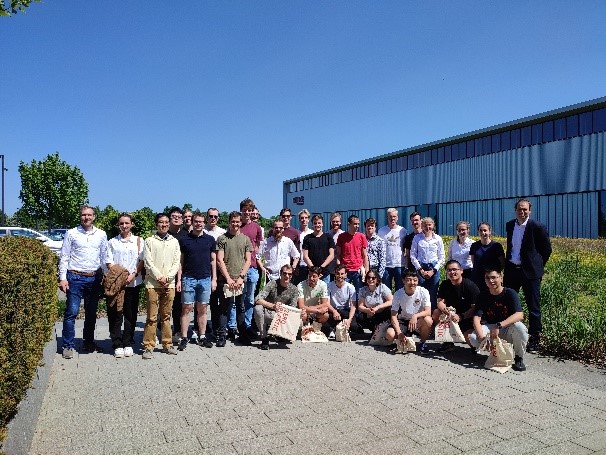

Whitsun excursion 2023

Whitsun week has established itself as an excursion week at the Karlsruhe Institute of Technology. This year, Mobima offered 23 students the opportunity to take a look behind the scenes at three companies: Fendt, part of the AGCO Group, in Marktoberdorf, HAWE Hydraulik in Kaufbeuren and Liebherr in Bischofshofen.

After an early departure from Karlsruhe, we reached Marktoberdorf by bus in the morning. The visit to Fendt began with a short presentation about the company and its history. We were then given a tour of the factory premises and were able to see the entire tractor production process from start to finish. The production of all tractors on a single production line, from the small 200 series to the world's largest standard tractors of the 1000 series, was particularly exciting. After lunch in the afternoon, there were specialist presentations on the up-and-coming technologies at Fendt. We also had the opportunity to ask our technical questions and discuss future developments. The visit was rounded off with a tour of the Product Forum, where we were able to see various machines up close.

In the afternoon, we continued our journey by bus to the Klosterhotel Irrsee, where we were able to meet some HAWE engineers over dinner. The next morning, we visited HAWE's production site in nearby Kaufbeuren. After a company presentation, we were given an in-depth insight into the production processes during an extensive factory tour. The ultra-modern and well-designed plant impressed us in many places with its order and structure, among other things. The design with plenty of indirect daylight not only creates a pleasant working atmosphere but also reduces electricity consumption. After lunch, we visited the testing department, where we were introduced to exciting aspects of hydraulic testing in lectures and test presentations - including a burst test.

We then made our way to Bischofshofen. There, too, we made our first contacts with Liebherr engineers over dinner. The next morning began with a series of specialist presentations from various areas of development. The wide range of topics gave us an insight into the complex development of wheel loaders. Lunch was followed by a factory tour that showed us wheel loader production from the raw sheet metal to final acceptance. We followed the entire production process of the machines around the site and were then shown some wheel loaders in action. Particularly impressive: a wheel loader without an operator in the cab, but controlled from the office.

The three intensive days ended with the bus ride back to Karlsruhe. The three companies gave us a comprehensive insight into their plants and presented themselves as attractive employers.

Many thanks to the companies, all employees involved and all participants!

Excursion to John Deere

On April 5, 2023, an excursion to the John Deere plant in Mannheim took place as part of the "Tractors" lecture of the Mobile Machinery department. 23 students took part in the excursion and gained exciting insights into tractor production and John Deere's corporate strategy.

The day's activities were very varied and diverse. A company presentation was followed by a factory tour, during which the students were given an insight into highly automated tractor production. They then visited the John Deere Museum, which offers a vivid overview of John Deere's tractor development. Finally, there was a discussion round in which the students had the opportunity to ask questions to representatives from John Deere and exchange ideas.

The John Deere plant in Mannheim is the company's largest plant outside the USA and is therefore an important location for European production. The two millionth tractor rolled off the production line just two weeks ago.

Overall, the excursion was a complete success and offered the students a valuable opportunity to experience the practical implementation of the content taught in the course.

9th symposium on hybrid and energy-efficient drives for mobile machinery

On February 28, the 9th symposium "Hybrid and energy-efficient drives for mobile machinery" took place in Karlsruhe with around 170 experts from science and industry.

The conference was organized by FVA GmbH with scientific support from the KIT's Mobile Machinery Division (Mobima).

At the evening event before the conference, participants were able to exchange ideas in a convivial atmosphere and gain an insight into the current research topics at Mobima and the other parts of the Institute of Automotive Systems Technology (FAST). The evening event was supported by the sponsorship of the companies Bosch Rexroth, AGCO Fendt and HSM Hohenloher Spezial-Maschinenbau.

The conference was opened the next day by Prof. Dr.-Ing. Marcus Geimer and began with a keynote speech by Patrick Ahlbrand from CLAAS on the topic of "Efficient and sustainable use of agricultural machinery". In the second keynote speech on "Sustainability - A term makes a career" by Prof. Dr. Dr. h.c. Bastian Kaiser from the University of Applied Forest Sciences in Rottenburg gave participants a new perspective on the term "sustainability".

This was followed by exciting presentations in the sessions "Innovative forestry technology", "Electrified machinery" and "Energy-efficient components". The event concluded with contributions on the topic of "Climate-neutral drives".

The importance of hybridization and increased efficiency in the field of mobile machinery became clear in the 12 technical contributions. The contributions from industry and research showed that the topics of climate neutrality and sustainability are also the main drivers of development in the field of mobile machinery. In particular, it became clear that the electrification or hybridization of travel and work drives offers great potential for increasing efficiency. Furthermore, the use of hydrogen as an energy source was also addressed several times as an important research topic.

During the breaks between the presentations, participants were able to find out about new products and innovations from Bosch Rexroth, Hydac, InMach, RheinTacho and Shimadzu at the trade exhibition.

We would like to thank the sponsors, exhibitors, speakers and all participants for the successful event and look forward to the tenth anniversary of the event in 2025, which has already been announced.

The conference proceedings published for the event with ISBN 978-3-7315-1260-8 will be made available free of charge in digital form via the KIT library.

Program Committee

Dr.-Ing. Frank Bauer, Prof. Dr. Ludger Frerichs, Prof. Dr. Gerhard Geerling, Prof. Dr.-Ing. Marcus Geimer, Christian Kunze, Dr.-Ing. Benno Pichlmaier, Dr. Bernd Vahlensieck

Whitsun excursion 2022

After the Whitsun excursions were held virtually in the past two years due to the pandemic situation, Mobima organized this year's excursion in person again. With a group of 12 students and research assistants, we visited the companies CLAAS in Harsewinkel, Lemken in Alpen and Sulzer Pumpen in Bruchsal over three days.

Tuesday, June 07, 2022

Early Tuesday morning, we set off from Karlsruhe in the direction of Harsewinkel. Once there, we had a short time to look around the town center of the small town in Münsterland before we were welcomed by CLAAS at 1:30 pm. The start and end point of our excursion at CLAAS was the Technoparc, where the agricultural machinery manufacturer's products are exhibited on an area of over 2,500m2 and information on the history of the company is provided. After the welcome and a short company presentation, a guided tour of the production halls was on the agenda. Among other things, we were able to see the new production line for manufacturing the two combine harvester models Lexion and Trion, which was only completed last year. Back at the Technoparc, we were treated to an exciting technical presentation and information on joining and pursuing a career at CLAAS.

After a quick check-in at the nearby hotel, we were invited to dinner together on Tuesday evening at the Greenhouse, CLAAS' digital ideas center. There we had the great opportunity to talk to five CLAAS employees about a wide range of topics in a relaxed atmosphere.

Wednesday, June 08, 2022

The second day of our three-day excursion took us from Harsewinkel to Alpen in the north-west of North Rhine-Westphalia. This is where the Lemken family business is based and manufactures various tillage implements. At 11:30 a.m. we were welcomed at the AgroForum there and provided with initial information about the products and the company's history. During the subsequent factory tour, we were shown the various steps involved in the manufacture of cultivators, plows and other tillage implements (including metal processing, painting and assembly). We were then given information about the career opportunities at Lemken. Finally, we had another opportunity to discuss any questions we had.

After our visit to Lemken, we headed south again to Bonn, where we checked into a centrally located hotel. From there, we walked together to the old town of the former German capital, enjoyed dinner together and rounded off the evening.

Thursday, June 09, 2023

On the third and final day, we drove from Bonn to Bruchsal in the morning. There we were welcomed by the company Sulzer Pumpen. As on the two previous days, a varied program awaited us at Sulzer: After a brief company and product presentation, we split into two groups for the factory tour and were given impressive insights into production by three employees from different departments. In addition to various metalworking processes, we also got to see the large test bays. A presentation by the HR department on joining and careers at Sulzer was followed by an open discussion round.

Fortunately, we didn't have far to go from Bruchsal to Karlsruhe, so we arrived back at Campus East at 6 p.m. on Thursday after three very interesting days of excursions.

Many thanks to the companies, all employees involved and all participants!

KIT - Campus Day 2022

In order to give prospective students an impression of the institute's research and the possibilities of studying mechanical engineering, the Mobile Machinery department also took part in the first Campus Day of the Karlsruhe Institute of Technology on May 14, 2022. In addition to lectures on the course of study, application, etc., prospective students were able to get an impression of the application of mechanical engineering studies at various information stands of the Faculty of Mechanical Engineering in the courtyard of honor. At the information stand of the Mobile Machinery Department, the students were particularly enthusiastic about the demonstrator of a Vario gearbox. Employees of the institute explained the basic functioning of the gearbox to the young people, giving them an impression of the complexity but also the possibilities of mechanical engineering. A Fendt Vario tractor, which is equipped with the transmission shown in the demonstrator and is used in research projects with additional sensors, was on display right next to it.

After two years of almost exclusively digital information events, direct communication was certainly helpful for prospective students to get a better impression of studying and the university environment. Mobima will also be happy to take part in future Campus Days in order to continue facilitating this direct exchange.

Virtual Whitsun excursion 2021

As in the previous year, the pandemic situation did not allow the excursion to take place as usual. Mobima therefore organized the 2021 Whitsun excursion in virtual format. This enabled us to "visit" Liebherr in Bischofshofen (Austria) and Danfoss in Neumünster on one day. On the second day, there was also a virtual visit to Bosch Rexroth in Horb, Baden-Württemberg.

On the Wednesday morning of Pentecost week, around 80 students and some Mobima employees gathered in front of their PCs to take part in the virtual excursion. The first company to take part was Liebherr from Bischofshofen, which had prepared a two-and-a-half-hour program. After a short company presentation, there were in-depth insights into various aspects of wheel loaders, from design, electronics and software development to future topics relating to automation systems and digitalization. The classic factory tour was presented in an exciting virtual format with short videos of the individual production steps. Information on joining the company and careers was also presented and there was always the opportunity for open discussion.

From Austria, the tour continued in the afternoon to the north of Germany. Danfoss also had an exciting and varied program to offer from Neumünster. Once again, interesting video recordings from the production facilities were shown. In addition, a live link to another site in Nordborg (Denmark) provided further insights into the company. The subsequent specialist presentations focused on system development and virtual commissioning and led to an exciting discussion afterwards. The students were also presented with exclusive opportunities for internships and dissertations.

The Whitsun excursion concluded with a virtual visit to Bosch Rexroth in Horb on the following Thursday morning. After an introduction to the company Bosch Rexroth and the world of hydraulics, exciting topics from the cooperation between Mobima and Bosch Rexroth were presented by doctoral students and young professionals. The subsequent keynote speech about the soft skills an engineer needs led to a discussion about career opportunities and led to exciting conversations.

Looking back, the 2021 Whitsun excursion was once again a complete success. The virtual format made it possible to visit three companies over 1000 km apart within two days. While the companies had the opportunity to present themselves and their products, the students gained exciting insights into the industry, current research topics and the field of work of an engineer. Nevertheless, we are very much looking forward to it and are optimistic that we will be able to organize our Whitsun excursion again in the future with visits to the companies on site.

8th symposium on hybrid and energy-efficient drives for mobile machinery

On February 23rd, the 8th symposium "Hybrid and energy-efficient drives for mobile machinery" took place, for the first time as a digital event due to the Covid-19 pandemic. Prof. Dr.-Ing. Marcus Geimer welcomed around 130 experts from industry and science to the online conference platform.

The conference was organized by the Mobile Machinery Division of the Karlsruhe Institute of Technology (KIT) and the German Engineering Federation (VDMA) in cooperation with the Scientific Association for Mobile Machinery.

While the focus in 2019 was on the integration of electric and hybrid drives, as well as their operation and energy storage, this conference presented and discussed various development methods in addition to innovative control and driving strategies.

The symposium opened with a presentation by the Forschungsvereinigung Antriebstechnik e.V. on the effects of the fuel cell strategy on mechanical and plant engineering, followed by a presentation on the networking of drive systems by DEUTZ AG. In the following session, which focused on smart machine control and driving strategies, the companies ZF Friedrichshafen AG, RWTH Aachen, Danfoss Power Solutions GmbH & Co. OHG and TU Braunschweig presented new driving strategies, hydraulic multi-pressure systems, electrified wheel loaders and flushing and feeding systems. After the lunch break, Greening GmbH & Co KG, Ravensburg-Weingarten University of Applied Sciences, stoba e-Systems GmbH and RWTH Aachen University presented the current status of implementing and using electric drives in terms of battery systems, cooling, integrated drives and metrological testing. The final session dealt with the topic of development methodologies. TU Dresden, FLUIDON Gesellschaft für Fluidtechnik mbH and Aalen University reported on sensor-controlled tool systems, digital twins for Industry 4.0 and application-adapted driving profiles.

Prof. Geimer concluded the 8th symposium with his closing remarks on the positive outcome of the current format and the outlook for the next symposium.

The 13 papers presented showed the great importance and the expected change in the field of hybrid and energy-efficient drives for mobile machinery in industry and science. New impulses are to be expected that will lead to both a reduction in emissions ando as well as added value in the form of increased efficiency and improved cost-effectiveness. We can look forward to the announced continuation in 2023.

During the breaks, participants were able to find out about current projects at the poster session accompanying the conference or discuss further questions with the speakers in the Speakers' Corner. 13 participants took the opportunity to present their posters in the poster session.

The accompanyingconference proceedingscan be obtained from KIT Scientific Publishing (ISBN 9783731510710). The presentation documents released by the speakers are available for download on the homepage(Mobima) of the Mobile Machinery Institute, KIT.

Program Committee

Prof. Dr. M. Geimer, Dipl.-Ing. P.-M. Synek, Prof. L. Frerichs, Dr. F. Bauer, Dr. B. Pichlmaier, Dr. B. Volpert, P. Lehr M. Sc., S. Metzger M.Sc.

70 years of agricultural engineering training in Karlsruhe

This year, the Institute of Mobile Machinery Mobima, Institute of Vehicle Systems Engineering, is celebrating the 70th anniversary of the course Tractors (formerly: Agricultural Machinery). Since 2007, honorary professor Martin Kremmer from John Deere has regularly supervised the course in the winter semester, thus continuing the long-standing tradition of cooperation between the specialist industry and KIT. Click here for the article.

Virtual Whitsun excursion 2020

As every year, Mobima also organized a Whitsun excursion in 2020. A trip to beautiful Bavaria to the companies Hawe in Kaufbeuren and Fendt in Marktoberdorf was planned. A visit to Putzmeister in Aichtal was also planned on the way to Bavaria.

However, due to the SARS-CoV-2 (coronavirus) pandemic, an excursion in the traditional sense was unfortunately not possible. In order to give students an insight into the companies, their working methods and content, the Whitsun excursion 2020 was therefore conducted virtually.

During Whitsun week, around 30 students and some Mobima employees gathered in front of their PCs. Putzmeister, manufacturer of concrete pumps, kicked off the program. Dr. Felix Weber, who had just completed his doctorate at Mobima, gave an insight into his research and the content of his work at Putzmeister. He has developed a new type of continuously pumping concrete pump to keep vibrations out of the lift mast. This was followed by a lively discussion with other employees of the company about their products, the use of concrete pumps and further research in this area.

The next day we went on to the Hawe company. Here, Mr. Specks presented Hawe's portfolio to us: from hydraulic valves to pumps and motors, their control systems and the engineering of entire hydraulic systems. He also let us participate in Hawe's research projects and showed us (unfortunately only virtually) their new factory in Kaufbeuren, which is planned, built and operated according to the latest ideas of lean management. An interesting discussion concluded the visit.

In reality, it is not far from Kaufbeuren to Marktoberdorf. For us, it was only a few clicks away this year! At Fendt, Ms. Helbig awaited us with an extensive agenda. After the company presentation with a brand film, Dr. Benno Pichlmaier gave us a specialist lecture on the topic of "Sustainable Innovation", in which he presented the sustainable development not only of agriculture from Fendt's point of view. After this in-depth introduction to the subject matter and the Fendt company, we were then able to discuss the topic in the panel discussion "Talent? To Fendt." questions could be asked. Several Fendt employees from all areas and a current external graduate were virtually connected to the discussion round. An intensive dialog about development topics, job opportunities and final theses at Fendt ensued.

Looking back, we can say that the 2020 Whitsun excursion was a complete success. Despite the difficult current situation, the companies were able to show themselves on the one hand and the students were able to get a taste of industry on the other. In reality, an excursion is of course even more exciting. But, like so many at the moment, we made the best of the situation!

15 years of Mobima

Unfortunately, due to the coronavirus pandemic, we were unable to celebrate the 15th anniversary of the Mobile Machinery division. Nevertheless, we took the opportunity to produce a short review for the "Redtenbacher" magazine.

Enjoy reading it!

KIT - Open Day

As part of this year's EFFEKTE science festival, the KIT Open Day took place on June 29, 2019. KIT's centers, institutes, partners and university groups presented themselves on the grounds of Campus East. As a local institute, MOBIMA was strongly represented. The approximately 9,000 visitors were given a comprehensive insight into the institute's activities. Many of them marveled at the test benches, especially our acoustic all-wheel roller test bench. An L580 wheel loader was set up there, and we would like to take this opportunity to thank Liebherr for the loan. The visitors were impressed by the size of the machine, the test bench and its acoustic lining and asked many interesting questions. With an outside temperature of 34°C, the test stand was also very pleasant thanks to the air conditioning.

In addition to the infrastructure, the focus was also on presenting our research activities. Particular mention should be made here of the project "Learning control systems for mobile machinery (LernSmArt)" (https://www.fast.kit.edu/mobima/forschung_10966.php), which was represented with its own stand under the slogan "Agricultural technology 4.0". Visitors were able to find out about the activities of the research project at first hand. A research tractor with plow and baler was also on display. For the young and young at heart guests there was a pedal tractor course on which they could prove their skills, many thanks to our partner Müller Landmaschinen for providing the pedal tractor.

For those interested in technology and studying, there was plenty to learn about mobile machinery at three demonstrators from the apprenticeship program. At various stands, interested visitors were able to gain an insight into hydraulics and the behavior of pressure and volume flow, the structure and function of power-split transmissions and CAN bus technology.

All in all, Saturday was a successful open day for us and the KIT. Further reports and pictures can also be found on the general KIT website:

http://www.kit.edu/kit/pi_2019_086_erfolgreicher-tag-der-offenen-tur-am-kit.php

Whitsun excursion

The 2019 Whitsun excursion took us westwards to Zweibrücken, Boppard and Windhagen. There we visited a manufacturer of harvesting machines and two manufacturers of road construction machines. We set up camp for the night in Koblenz, which gave us an insight into the beautiful little town on the Moselle and Rhine.

Day 1: Tuesday, 11.6.2019

We met punctually at 6 a.m. at the MOBIMA Institute on Campus East and then took the Karlsruhe Lions team bus to Zweibrücken 15 minutes later. Once there, we were welcomed at 9 a.m. for a short presentation of the company followed by a tour of the John Deere factory. Combine harvesters and forage harvesters are developed and manufactured there. Over a distance of 6 km, we were able to take a look at the entire production process. After refreshments in the visitor center, four young employees presented their experiences in the company and answered all our questions about "John Deere as an employer". Finally, John Deere gave us the chance to get rid of all our technical questions during an expert discussion about combine harvesters and forage harvesters. We were then bid farewell with coffee and a few sweet treats.

Well fortified, we made our way to Koblenz, where we checked into our hotel at around 5 pm. The WVMA e.V. invited us to the Alte Brauhaus for dinner. This was the first brewery in Koblenz at the end of the 17th century, as we learned during the city tour the next day. After dinner, the group split up. Some went back to the hotel and the rest ended the evening in an Irish pub.

Day 2: Wednesday, 12.6.2019

At 8 a.m. on the dot, we drove 30 minutes from Koblenz to Boppard to visit the company BOMAG. BOMAG is an expert in the field of compactors and waste compactors, road pavers and milling machines as well as hand-guided machines for soil compaction. At the beginning, we were introduced to the company and its product range, and then we were given a factory tour to see the production processes of these machines. After the factory tour, we had the opportunity to talk to the company's engineers in a relaxed atmosphere over a lunch snack. At 2 p.m. we made our way back to Koblenz.

There we had the opportunity to discover the old town and the highlights of the city on a 2-hour guided tour at 4 pm. Livened up by lots of interesting facts about buildings and the history of the city, the tour ended at the Deutsches Eck, where the Rhine meets the Moselle. From there, we made our way to the Koblenz wine village to have dinner on the banks of the Rhine. Fortunately, we had a very sunny evening and so it was a good idea to end it in a beer garden right on the Deutsches Eck. Later in the evening, the group split up. Some went back to the hotel after an eventful day. A few more adventurous ones explored the pub culture of Koblenz.

Day 3: Thursday, 13.6.2019

A little earlier than the day before, we made our way to the Wirtgen company in Windhagen at 7:45 am. A broad product portfolio of machines for road construction and mining awaited us there. Under the umbrella organization John Deere, the Wirtgen Group unites machines for the entire road construction process. After an introduction to the company, we were given a tour of the plant and were able to take a look at the company's current production. Over lunch, we then had the chance to talk to employees about the products and the company.

At 13:30 we made our way back to Karlsruhe. We arrived back in Karlsruhe at 17:15. With many new impressions and perhaps also new friendships, we said goodbye after three great days.

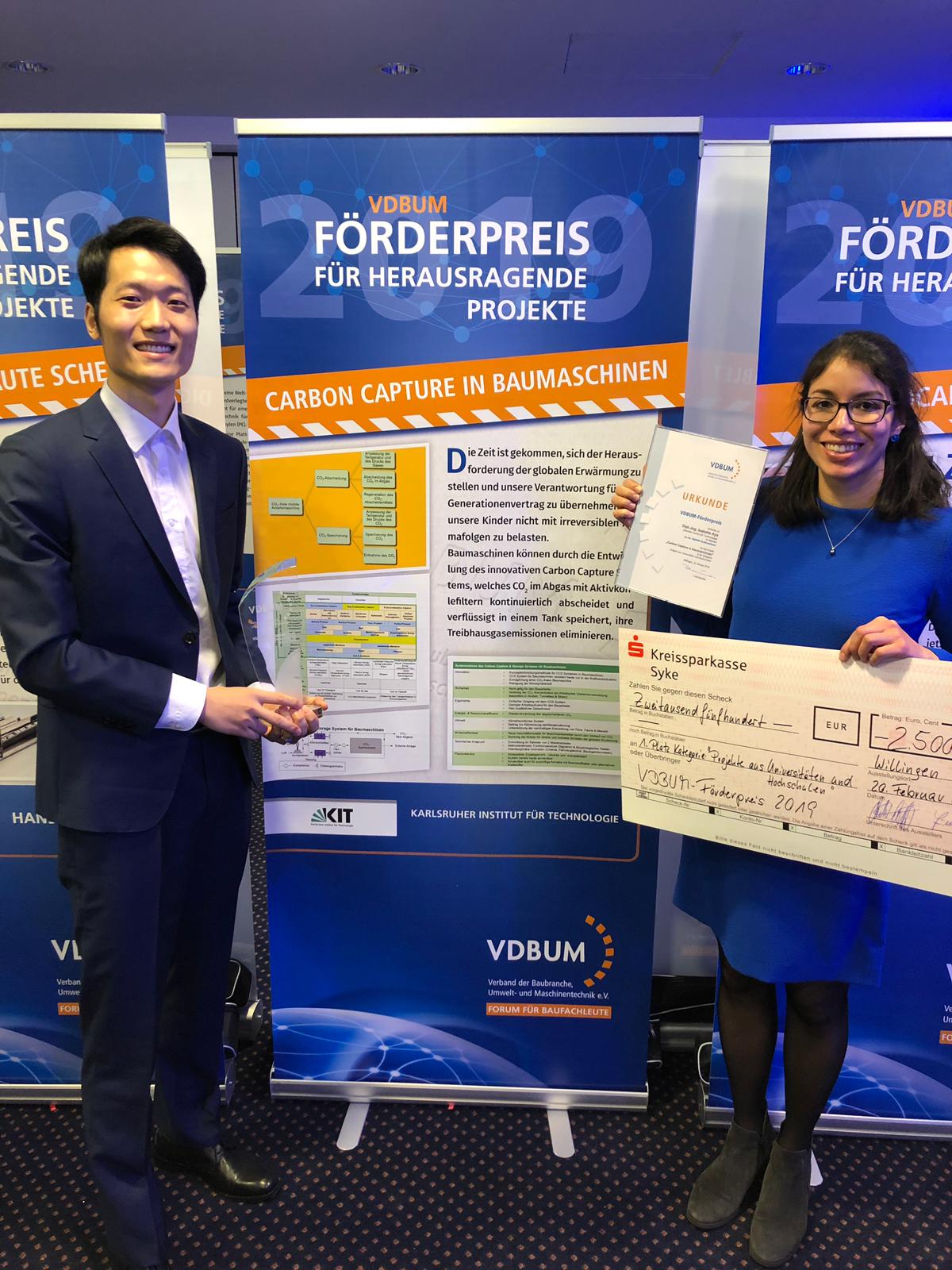

VDBUM Sponsorship Award 2019

Brief description

Carbon capture in construction machinery

Brief description of the innovation / innovative project

The time has come to face up to the challenge of global warming and to assume our responsibility for the intergenerational contract so as not to burden our children with irreversible climate consequences.

Construction machines can eliminate their greenhouse gas emissions by developing the innovative Carbon Capture System, which continuously capturesCO2 in the exhaust gas with activated carbon filters and stores it in liquid form in a tank

Detailed description of the innovation

Motivated by climate change, the EU has set a target to reduce greenhouse gas emissions by 85-95% by 2050 compared to 1990 levels. Taking into account methane from animals and assuming that construction machinery has a maximum lifespan of 18 years, this means that no moreCO2-emitting construction machinery can be sold by 2032 at the latest. Current forecasts from the EEA predict that the introduction of further guidelines and measures to transform into sustainable systems will not achieve the targets.

One possible solution is the development of a Carbon Capture Storage (CCS) for construction machinery, which captures theCO2 emissions produced. The functions ofCO2 capture and storage required for the system were broken down in a functional analysis diagram, see Fig.1. On this basis, all possible CCS concepts for construction machinery were listed using the morphological box method, see Fig.2. The application of this method leads to the system in Fig.3. The concept guarantees a continuousCO2 capture rate of over 99% by means of two activated carbon filters arranged in parallel. First, the exhaust gas is cooled to 60°C using air from the environment, then theCO2 is separated from the air and exhaust gas using one of the two activated carbon filters and finally theCO2-free gas is released into the atmosphere. When the filter is completely filled withCO2, the exhaust gas is routed to the other filter via the three-way valve. In the meantime, the first filter is regenerated by heating it to 120°C to desorb theCO2. When one filter is in adsorption mode, the other filter is in desorption mode. The desorbedCO2 is finally stored in a tank at 30°C and 200bar liquid. The liquidCO2 can then be sold and reused for the production of e-fuels or for other industrial products. This creates new business models for construction machinery operators. The additional workload of the system for the worker is low, as only theCO2 storage tank needs to be emptied. This can be done at the same time as filling the fuel tank without taking up any additional time.

The resulting limitation of climate change supports the sustainable development of flora, fauna and humans. IncreasedCO2 concentrations can lead to headaches, nausea and even death. Especially when working in pits, tunnels or mines, where theCO2 concentration is higher, the workplace becomes safer for construction workers.

The LSU Foundation states that direct damage and indirect consequences such as adaptation measures due to global warming cost €30 per tCO2. Using the example of a diesel excavator with a service life of 10,000 hours, this corresponds to 789 tCO2 emissions and €24k. This clearly shows that this innovation is quite economical.

CCS for mobile machines are not yet used today, but can already be used today, as the weight, volume and energy consumption for the machines are justifiable and therefore practical (e.g. for a 27t excavator: 1.5-6.5% additional weight, 1.3m³ additional volume, 9% additional energy). The proposed unique sustainable system, which even cleans the air, enables new business models for the construction industry and gives the construction machine a new reputation as a climate-friendly machine. The CCS is also ideally suited for the use of future drives with fuel cells or alternative fuels.

Short video:

https://www.youtube.com/watch?v=duByzVc-AHw&feature=youtu.be

7th symposium on hybrid and energy-efficient drives for mobile machinery

The 7th symposium "Hybrid and energy-efficient drives for mobile machinery", which has now established itself as a recognized expert forum in the field of mobile machinery, took place on 19/20 February. Prof. Dr.-Ing. Marcus Geimer welcomed almost 200 experts from industry and science to the Akademie Hotel Karlsruhe. The previous evening event on February 19 in the institute's own test halls was already used for a lively cross-company meeting with professional exchange in a convivial atmosphere. The conference was organized by the Mobile Machinery Division of the Karlsruhe Institute of Technology (KIT) and the German Engineering Federation (VDMA) in cooperation with the Scientific Association for Mobile Machinery.

While the focus in 2007 was on ideas, concepts and initial solutions for hybrid drives, this conference addressed not only the successful integration of electric and hybrid drives, but also the question of new operating strategies and energy storage systems with the aim of significantly reducing emissions from mobile machinery through to a "zero emission" machine.

The symposium opened with a presentation by PRIMAGAS Energie GmbH & Co. KG on BioLPG as an alternative for modern engines, followed by the presentation of DEUTZ AG's hybrid and electrification strategy, which was built on by GreenIng GmbH & Co. KG's presentation on challenges and opportunities in the electrification of mobile machinery.

In the following session, which focused on energy-efficient drives, the companies Danfoss Power Solution, Logset Oy, Dana Rexroth and the TU Munich research institute presented new transmission approaches, hybrid solutions for forestry machinery and traction-supporting attachments. After the lunch break, Ostfalia University of Applied Sciences and RWTH Aachen University presented the current status, possible areas of application and potential in the domain of electro-hydraulic linear drives. In a parallel session, hybrid drive technologies were presented both for individual components and for complete vehicles with the aim of reducing emissions and increasing efficiency.

The final session dealt with the topic of alternative drives. Following a presentation by KIT on the idea of an emission-free mobile work machine, Stieler Technologie- & Marketing Beratung GmbH & Co. KG presented a study on drive options that are already being implemented and planned for the coming years. Finally, DLM Dampflokomotiv- und Maschinenfabrik AG reported on steam engines with high energy density as an alternative drive solution, before Prof. Geimer closed the 7th symposium with his closing remarks.

The total of 16 papers presented showed the great importance and the expected change in the field of hybrid drives for mobile machinery, in industry and science. New impulses can be expected that will bring both a reduction in emissions and added value in the form of increased efficiency and improved cost-effectiveness. We can look forward to the announced continuation in 2021.

During the breaks, participants were able to exchange ideas with component, system and control system manufacturers at the trade exhibition accompanying the conference. Seven companies took the opportunity to present their products and ideas.

The accompanying conference proceedings can be obtained from KIT Scientific Publishing (ISBN 9783731508731). The presentation documents released by the speakers are available for download on the homepage(Mobima) of the Mobile Machinery Institute, KIT.

Program committee:

Prof. Dr. M. Geimer, Dipl.-Ing. P.-M. Synek, M.Sc. L. Brinkschulte, Prof. L. Frerichs, Dr. F. Bauer, Dr. B. Pichlmaier, Dr. B. Volpert

Report on the 2018 MOBIMA Whitsun excursion

Day 1: Tuesday, 22.5.2018

We met in front of the MOBIMA Institute on Campus East at 5:45. 6:00 a.m. was the departure time. Off we went to Kessler in Abtsgmünd in Swabia. The journey took around 3 hours. We received a warm welcome at Kessler. It started with a presentation about the company and its history. This was followed by a detailed tour of the 3 plants. Kessler is a gearbox and axle manufacturer that develops its own customized products and carries out many different durability tests. It was very interesting to see the complete manufacturing process.

After the factory tour, we went to the canteen. All the participants sat at a long table and had a pleasant meal with one of the company owners. After the meal, we had a presentation about the company's products and its future. Then we went to a very interesting museum where many natural phenomena are explained interactively. After visiting the museum, we took the bus directly to Regensburg. When we arrived, we were allocated our hotel rooms and after a 45-minute break we went for dinner in a typical German brewery. The food was delicious and everyone had a good time. Afterwards, the group split up. One part went back to the hotel and the other part went to the Regensburg folk festival. That was the end of the first day

Day 2: Wednesday, 23.5.2018

We left the hotel in Regensburg for Holmer on time at 8:30. We received a warm welcome at Holmer. The program began with a presentation about the history of the company. Afterwards, as on the previous day, we had a detailed factory tour during which many questions were answered. Holmer is a medium-sized company that builds fairly large agricultural machinery. So big that you feel like a dwarf standing next to them. After the factory tour, we had a very interesting presentation about farming and the challenges. Afterwards, Holmer provided us with Bavarian veal sausage and pretzels. After the meal, we drove straight on to Passau. After checking in, we walked into the city. We walked to the old town, where we enjoyed the wonderful weather. At 7 pm we met up again at a brewery. We had dinner there and then continued exploring the city in the evening. That was the end of day 2.

Day 3: Thursday, 24.5.2018

We got up relaxed and had breakfast. We took the bus to the city shortly before 10am. The city tour started at 10 am. The tour was very interactive and entertaining. We learned a lot about the history of the city. The tour ended with a nice photo.

At 13:30 we drove on to ZF in Passau. The program typically started with a short presentation about the history of the company. This was followed by a tour of the plant. The plant in Passau is very large compared to the Holmer plant. Vehicle axles and gearboxes are produced there. ZF produces 90% of the world's bus axles. We were shown around the plant for about an hour. This was followed by a short break before we had the pleasure of another guided tour through the test. There we split up into 2 groups, which among other things looked at several service life tests for different components and assemblies. After the tour, we left for Karlsruhe at around 5 pm and arrived at the institute at around 10:45 pm.

In short: It was a very interesting and exciting excursion where we got to know 3 companies and had a lot of fun at the same time.

Excursion to Kramer-Werke GmbH

As part of the lecture "Design of mobile machinery", a wheel loader was designed in the 2018/2019 winter semester. The lecture included an excursion to Kramer-Werke GmbH in Pfullendorf at the end of the semester. During this excursion, students gained further knowledge about the development of wheel loaders through various technical presentations by employees. The students then went on a tour of the production hall. There they were given an insight into the various work steps involved in the manufacture of wheel loaders in different performance classes. After lunch, the highlight of the day was the machine demonstration and vehicle testing. The limits of the wheel loaders were demonstrated on an internal test site and each student was allowed to try out the machines for themselves. The day was rounded off with presentations by the student groups on the topics covered in the lecture.

Kamaro wins the Field Robot Event 2017

At the Field Robot Event (FRE), the unofficial world championship for field robots, student teams from universities all over Europe and beyond meet every year to pit their constructions against each other in a competition in the field.

The FRE is held by a different university each year, always on arable land and always with real plants. On the competition field, usually planted with young maize plants, the robots have to navigate flawlessly and recognize weeds and obstacles. All this without GPS, because the field is all about millimeters, whatever the weather.

The students are building several robotic vehicles on their own, with all the mechanics, electronics and data processing coming from mechanical engineers, electrical engineers and computer scientists at KIT.

After many years of development, during which many a corn plant and electronics had to lose their lives, we achieved our greatest success at the FRE 2017, hosted by Harper Adams University in England.

The overall victory across all disciplines, and the successful defense of the title in the freestyle presentation. Kamaro was able to achieve a partial victory (1st place), especially in Field Mapping (Task 3) with a convincing map of the field, which mapped areas with simulated weeds with centimeter accuracy. In addition, the robot's consistent driving performance across all tasks was one of the main reasons for its excellent ranking.

6th symposium "Hybrid and energy-efficient drives for mobile machinery"

On 14/15 February 2017, the 6th "Hybrid and energy-efficient drives for mobile machinery" symposium took place, which has established itself as a recognized forum in the field of mobile machinery. Prof. Dr.-Ing. Marcus Geimer welcomed almost 200 experts from industry and science. The event on the eve of the conference was already used for a lively cross-company meeting with professional exchange in a convivial atmosphere. The conference was organized by the Mobile Machinery Division of the Karlsruhe Institute of Technology (KIT) and the German Engineering Federation (VDMA) in cooperation with the Scientific Association for Mobile Machinery.

While the first symposia - the event took place in 2007 - focused on ideas, concepts and initial solution implementations, the 6th symposium in 2017 addressed topics relating to the testing and successful integration of electric and hybrid drives in mobile machinery.

Three introductory keynote speeches from industry and science gave participants the opportunity to think outside the box. Starting with a presentation on a battery electric wheel loader by Mr. Franz-Josef Paus from Paus Hermann Maschinenfabrik GmbH, the development trends in rail vehicles were presented by Prof. Dr.-Ing. Peter Gratzfeld, KIT Subinstitute Railway Systems Technology, and the development perspectives of electrical energy storage by Dr. Margret Wohlfahrt-Mehrens from the Helmholtz Institute Ulm.

In the following session, the companies Daimler AG and Weiss Mobiltechnik GmbH as well as the research institutions TU Braunschweig and KIT presented concepts as well as energy-efficient and hybrid drive topologies that have been put into series production and assessed their potential. After the lunch break, contributions on simulation and modelling by KIT and Liebherr Werk Bischofshofen GmbH showed the current status of simulation and calculation tools in various domains relating to optimization and energy efficiency. At the same time, HYDAC International GmbH, HAMM AG, TU Dresden and the Fraunhofer Institute presented a wide variety of hybrid drive systems. Finally, KIT, John Deere GmbH & Co. KG and Linde Material Handling GmbH reported on the use of electric and alternative drives in mobile machinery before Prof. Geimer closed the 6th symposium with his closing remarks.

Overall, the contributions presented showed the importance of the topic of hybrid drives for mobile machinery in industry and science. This is expected to provide new impetus for development, with benefits for the environment in the form of reduced CO2 emissions, as well as added value for industry in the form of increased productivity, improved cost-effectiveness and increased energy efficiency.

In addition to the presentations, participants had the opportunity to exchange ideas with component, system and control manufacturers at the accompanying trade exhibition during the breaks. Eight manufacturers took the opportunity to present their products and ideas.

The accompanying conference proceedings ![]() can be obtained from KIT Scientific Publishing (ISBN 978-3-7315-0601-0). The presentation documents are available for download on the homepage(Mobima) of the Mobile Machinery Institute, KIT.

can be obtained from KIT Scientific Publishing (ISBN 978-3-7315-0601-0). The presentation documents are available for download on the homepage(Mobima) of the Mobile Machinery Institute, KIT.

Program committee:

Prof. Dr. M. Geimer, Dipl.-Ing. I. Ays, Dipl.-Ing. P.-M. Synek, Prof. L. Frerichs, Dr. F. Bauer,

Dr. B. Pichlmaier, Dr. B. Volpert

9th Colloquium Mobile Hydraulics

On September 22 and 23, 2016, the 9th Colloquium on Mobile Hydraulics took place on the grounds of the Karlsruhe Institute of Technology. The conference is organized every two years by the Mobile Machinery Institute (Mobima) of the KIT and the Institute for Mobile Machines and Commercial Vehicles (IMN) of the TU Braunschweig together with the German Engineering Federation (VDMA) from Frankfurt. The event enjoys a special status in specialist circles, as the solutions implemented are shown on demonstrators and discussed. This means that the theoretical content of the presentations can also be demonstrated on a practical object.

The 9th Mobile Hydraulics Colloquium was attended by 130 interested parties from industry and university research. The current state of research in the field of mobile hydraulics was presented and discussed in nine high-quality papers. The main topics of the first day were new mobile hydraulic concepts as well as hydraulic fluids and components for traction and work drives.

As a special feature this year, Dutch hydraulics expert Dr. Peter Achten from Innas BV was invited to give a keynote speech entitled "A new perspective for hydraulics". In the 45 minutes or so of his speech, Dr. Achten recommended changing perspectives from time to time and redesigning the future with new, low-loss hydraulic systems. The joint efforts of all those involved from industry and university research are required.

On the evening of the first day, the evening event associated with the conference took place in the test halls of the Mobile Machinery Institute on the KIT East Campus, in keeping with tradition. In addition to a sumptuous buffet, the evening program included a demonstration of two test rigs from the Mobile Machinery Institute, which were presented during the lecture sessions. The first was a component test rig, which was used to investigate the effectiveness of a demand-adapted relief of the tribological contacts of axial piston machines as an optimization measure. The second system was a complete single-circuit load sensing system for the working hydraulics of a hydraulic excavator, which was used to investigate the increase in efficiency through the reduction of system-related pressure losses.

At the same time, guided tours of the subinstitute's testing facilities were offered. The stand of the student group KAMARO Engineering e.V., who presented the results of their work - a self-propelled robot for the future of agriculture - was a special feature of the evening for many participants.

The presentations on the second day dealt with the topic of "Energy efficiency in mobile hydraulic systems". For example, a presentation was given on an efficiency-optimized "Skidder" forestry crane from Ritter, which owes a 14% increase in efficiency compared to the original vehicle to its innovative control concept using electrohydraulic demand flow control. The optimized machine was available as a demonstrator as part of the machine exhibition and was enthusiastically put through its paces in practical use by some of the conference guests.

All contributions to the conference are available for free download in the form of a conference proceedings on the KSP-Verlag homepage. The content can be accessed via the following link:

http://www.ksp.kit.edu/9783731505730

The 10th Mobile Hydraulics Colloquium will take place in Braunschweig in late summer / fall 2018.

Fiducia/AOK Marathon in Karlsruhe

On September 20, 2015, the Fiducia/AOK Marathon took place in Karlsruhe. The team was to be made up of employees from the Mobile Machinery department at the Karlsruhe Institute of Technology (KIT) and KIT students. During the race, the team was to wear T-shirts representing the Mobile Machinery department.

The aim was to promote communication between students and employees (team building) and to encourage potential young talent to take an interest in mobile machinery.

The race takes place every year throughout Karlsruhe. KIT students are represented both as participants and spectators.

Furthermore, the Fiducia/AOK Marathon is known for the fact that companies from the Karlsruhe area (as far as Pforzheim, approx. 30 km) take part in the marathon. This was an opportunity to make the Mobile Machinery Division known to potential project partners.

The team representing the field of mobile machinery was represented by the following persons:

- Isabelle Ays

- Danilo Engelmann

- Hagen Neurath (former student of the Mobile Machinery Department)

Mobile Machines 2015

The 4th symposium "Mobile Machines - Safety and Driver Assistance for Mobile Machinery" took place in Karlsruhe from May 5 to 6, 2015. This conference is jointly organized by Hanser-Verlag and the Chair of Mobile Machinery at KIT.

Over 100 participants attended the presentations on trends in the increasing automation of agricultural, construction and municipal vehicles as well as industrial trucks. The conference concluded with a tour of the Herrenknecht company, which demonstrated tunnel boring technology and the construction of the machines. The conference was accompanied by a trade exhibition presenting practical solutions.

Under the following link you will find furthernformation on the website of Hanser-Verlag.

10 years of research for mobile machinery

On March 20, 2015, the Chair of Mobile Machinery (Mobima) at KIT and the MOBIMA e.V. support association celebrated the 10th anniversary of the endowed chair with a festive colloquium. Around 70 people took part in the event.

On April 1, 2005, the endowed chair initially began its work in rooms at the Fasanengarten of the former University of Karlsruhe (TH), which has now merged with the Karlsruhe Research Center to form the Karlsruhe Institute of Technology (KIT). Rapid growth was possible with the support of the founders, so that after 10 years the chair with more than 10 employees has now become a recognized research center in the field of drive and control technology.

Today, Mobima uses extensive research facilities together with other colleagues from the Institute of Automotive Systems Technology (FAST) on Campus East. Research work can be carried out in the field of systems technology as well as investigations of entire vehicles. Last but not least, the acoustic all-wheel roller test bench at Mobima provides a globally unique research infrastructure for the machines.

Under the following link you will find a detailed report on the colloquium, which was published in the trade journal Mobile Maschinen.

by Prof. Dr.-Ing. Marcus Geimer

Activities 2014

Excursion to the John Deere plants in Mannheim

Excursion 2014 - Visit to Liebherr and SEW

Book - Basics of mobile machinery

Hands-on teaching examples: Mobile machines in practical use

Excursion to the John Deere plants in Mannheim

As a special highlight of this year's "Tractors" lecture, the participants had the opportunity to take an exclusive tour of the John Deere plants in Mannheim. After a short company presentation, they immediately headed towards the factory halls to see one of the most modern tractor production facilities in the world. In addition to transmission production and the assembly line, there was also a live demonstration of a brand new tractor produced in Mannheim. The day was rounded off with personal discussions in the forum and a presentation of the extensive range of machinery.

Thank you very much for this excellent day with many remarkable impressions!

Excursion 2014 - Visit to Liebherr and SEW

This year's excursion took around 30 participants to the Liebherr plant in Ehingen and to SEW in Bruchsal. We received a very friendly welcome from the companies and were able to find out about the company structures, opportunities for internships, final theses and the first career entry, in addition to varied factory tours. In addition to the interesting insights into production at Liebherr, we will certainly remember the vehicle demonstrations of various telescopic and crawler cranes with their enormous dimensions. After all, the company holds the current world record for crawler cranes! The impressive quantities of printed circuit board production and the fully automated winding of electric motors at SEW will also remain a lasting memory. Many thanks to everyone involved, especially the company representatives from the respective specialist departments for the in-depth insights into their daily working environment!

Hands-on training examples: Mobile machines in practical use

Right at the start of the semester, the students on the "Powertrain of mobile machinery" course had a special opportunity to familiarize themselves with the lecture topic using practical examples. The various vehicles owned by the chair were used: the Fendt Vario, the Liebherr L 509 Stereo 6-tonne wheel loader and the battery-powered Linde E30 forklift truck. Both the various drive systems and the individual drive functions, which are part of the course, were explained and demonstrated in practice. The students had the opportunity to examine the machines in detail and ask questions. Several practical demonstrations of driving, working and steering hydraulics concluded the course. The course "Drive train of mobile machinery" deals with the topic of drive technology from the perspective of mobile machinery. In contrast to the widely known technologies from the automotive sector, the wide range of prevailing drive types in the work machinery sector is explained here. These include various types of (load) shift, stepless and power split transmissions, which are realized by means of mechanical, electrical, hydrostatic or hydrodynamic components. Other components such as axles and tires and related assemblies such as steering and working hydraulics round off the range of topics.

Mechanical Engineering Day/Institute Fair in AUDIMAX

The Faculty of Mechanical Engineering at KIT is organizing a Mechanical Engineering Day on Friday, July 19, 2013 as a forum and networking event for Karlsruhe's mechanical engineering institutes, partnering industrial and research companies and students.

The Chair of Mobile Machinery will once again be taking part in the event with exhibits and employees who are keen to engage in discussion and introduce future Master's students to the institute and the MOBIMA courses.

You can find the program under this LINK http://www.mach.kit.edu/download/Programm_Maschinenbautag_Internet.pdf

Whitsun excursion 2013 - Visiting Kramer, ZF and Bosch Rexroth

As part of this year's excursion week, around 30 students and employees from the Chair of Mobile Machinery spent three days between the Lake Constance region and Ulm. The program included visits to the companies Kramer Wacker Neuson in Pfullendorf, ZF in Friedrichshafen and Bosch Rexroth in Ulm. We received a very friendly welcome from the companies and were able to find out all about the company structures, opportunities for internships, dissertations and career entry in addition to a wide range of factory tours. Our physical well-being was also well catered for. Whether in the company's own canteen, the country inn or the Ulmer Innenstatt, there was something for everyone. In addition to the interesting insights into the companies we visited, we will certainly remember the live demonstrations of various wheel loaders on steep slopes, state-of-the-art test rigs and various construction vehicles, as well as an extraordinary guided tour of Ulm. Many thanks to everyone involved, especially the company representatives from the respective specialist departments for the in-depth insights into their daily working environment!

Rückblick auf die Fachtagung „Mobile Machines – Sicherheit und Fahrerassistenz für mobile Arbeitsmaschinen“ vom 14. und 15. Mai 2013 in Karlsruhe-Ettlingen

With a significant increase to over 110 participants, the interest in the symposium was impressively confirmed. The capacities of the conference facilities were thus completely exhausted.

Safety issues relating to mobile machinery and driver assistance systems were the focus of the first day. In addition to an overview of standards and practical examples, the topic of steer-by-wire was the subject of several presentations. It became clear that these control systems have now reached a safe level and can be found in practice.

The contribution to "Vision Zero", which aims to achieve accident-free driving, was also discussed intensively.

New operating concepts as well as safety and data management were the focus of the presentations on the second day. Participants and speakers agreed that products from the consumer industry cannot be used directly in machines. Nevertheless, a presentation on intuitive operating concepts demonstrated the trend towards rethinking traditional structures.

The conference was accompanied by a trade exhibition. Here, new technologies were discussed intensively, particularly during the breaks, and one or two ideas were certainly generated.

At the end of the presentations, a tour of the John Deere plants in Mannheim was offered, which the majority of conference visitors took advantage of. In addition to a tour and a visit to the final assembly line, experts from various areas of the company were available to answer questions.

All in all, it was a successful conference, which confirms the organizers' decision to continue the conference series in 2015.

Review of the symposium "Hybrid drives for mobile machinery" on February 19 and 20, 2013 in Karlsruhe

The 4th "Hybrid Drives for Mobile Machinery" symposium, which has now established itself as a recognized forum in the field of mobile machinery, took place on 19/20 February. Prof. Dr.-Ing. Marcus Geimer was able to welcome over 260 experts from industry and science, and the event the evening before was already used for a lively cross-company meeting with professional exchange in a convivial atmosphere. The conference was organized by the Chair of Mobile Machinery at the Karlsruhe Institute of Technology (KIT) in cooperation with the VDMA and the Scientific Association for Mobile Machinery.

While the focus at the beginning of the conference in 2007 was on concepts and ideas, this conference reported on successfully implemented prototypes and design tools for hybrid machines.

After Mr. Treusch from Daimler AG had opened the conference with an overview lecture entitled Hybrid at Daimler Trucks - Technology for the World, research results on the system design and operating strategy of mobile machinery were presented in lectures by the Technical University of Munich and the RWTH Aachen. This was followed by contributions from AGCO GmbH, the Karlsruhe Institute of Technology and IAV GmbH on assessing the potential of hybridized machines. After the lunch break, contributions on simulation and modeling from TU Kaiserslautern, Claas Industrietechnik GmbH and Liebherr-France SAS showed the current status of calculation tools and new electric drive solutions were presented. Finally, Jetter AG, Konecranes GmbH and TU Dresden reported on their practical experience with hybridized machines before Prof. Geimer closed the 4th symposium with his closing remarks.

In conclusion, it can certainly be said that hybrid technologies have established themselves as the state of the art on the market today. In addition, the conference proceedings produced to accompany the conference can be obtained from KIT Scientific Publishing (ISBN 978-3-86644-970-1).

7th Colloquium Mobile Hydraulics

On September 27 and 28, 2012, the 7th Colloquium on Mobile Hydraulics took place in and in front of the Audimax at KIT Campus South. The event takes place every two years, alternating between KIT and TU Braunschweig. The special feature is that the speakers exhibit a demonstration object or a demonstration machine alongside their lecture. This allows the theoretical content of the lectures to be demonstrated on a practical object.

The lecture series took place on September 27. After the opening by Professor Geimer, Professor Frerichs and Professor Lang from the Institute for Mobile Machines and Commercial Vehicles at the TU Braunschweig presented current mobile hydraulic activities at research institutions. This was followed by the specialist presentations, which were divided into the topics of "New mechatronic systems", "Hybrid drives and alternative drive concepts" and "Driving and working hydraulics". The main focus was on enhancements to existing functionalities and measures to increase the energy efficiency of mobile machinery.

The subsequent evening event took place in the test hall of the Institute of Vehicle Systems Engineering on Campus East. In an informal atmosphere, not only technical topics were discussed over dinner. An exhibition in the test hall and on the new chassis dynamometer framed the evening event.

On the following day, the machine demonstration took place again in the morning in front of the Audimax. The exhibits included a Claas telescopic handler, a Rauch two-disc fertilizer spreader, a wheel loader with parallel kinematic working equipment and a grape harvester from Ero Gerätebau. The event concluded with a lunchtime snack.

The next colloquium on mobile hydraulics is scheduled to take place on October 6/7, 2014 in Braunschweig. October 6/7, 2014 in Braunschweig.

Excursion 2012 - Visiting Liebherr, Hydac, John Deere and Daimler

As part of this year's excursion week, a total of 26 students and employees from the Chair of Mobile Machinery made their way to Colmar, Sulzbach, Zweibrücken and Wörth. The program included visits to the companies Liebherr-France, Hydac, John Deere and the Daimler AG Unimog plant. We received an extremely friendly welcome from the companies and were able to find out all about the company structures, opportunities for internships, final theses and starting a career, as well as a wide range of factory tours. We would like to thank Dr. Späth (Liebeherr), Dr. Bauer (Hydac), Dr. Beck (John Deere) and Dr. Wetzel (Daimler) for their excellent support. All the companies organized a very varied and interesting visit and also took excellent care of our physical well-being.

Special thanks also go to Mr. Mathias Dieter (Hydac), who took the time to join us for dinner. The wide range of information from the management perspective was certainly one of the highlights of this excursion.