Additive manufacturing

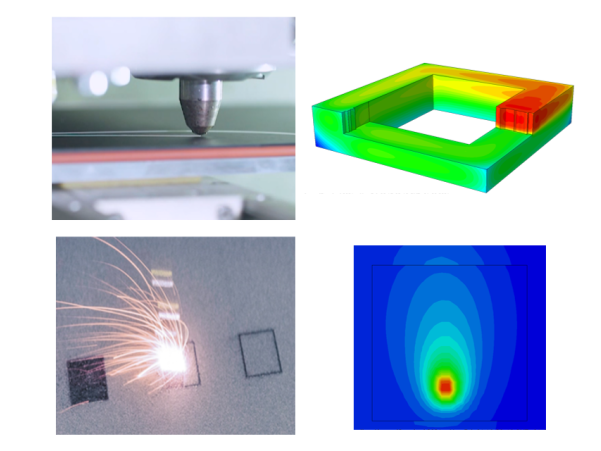

Additive manufacturing processes offer great potential with regard to geometrically complicated structures to be manufactured. We are researching new methods for modelling and design of such manufacturing processes. In particular, we are working on Laser Powder Bed Fusion (LPBF) and Fused Filament Fabrication (FFF). Special attention is focused on the observation of the process on different scale levels in order to predict the locally different as well as complex structural properties due to the underlying material properties as well as process control. Furthermore, we deal with the modeling of locally occurring interfaces.

Research focus

- Simulation of the printing process and prediction of the resulting temperature history at component level

- Warpage simulation based on the determined temperature history on component level

- Modeling of the FFF at the meso level for virtual characterization of the local properties of the printed structure

- Process hybridization

- Interfacial modeling

Research projects |

ContactM.Sc. Felix Frölich

M.Sc. Lukas Hof |

Selected publications in the research field

Frölich, F.

2025, December 15. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000188526

Frölich, F.; Di Nardo, M. E.; Krauß, C.; Heuer, A.; Liebig, W. V.; Wittemann, F.; Carlone, P.; Kärger, L.

2025. Additive Manufacturing, 113, Article no: 105023. doi:10.1016/j.addma.2025.105023

Hof, L.; Frölich, F.; Wittemann, F.; Kärger, L.

2025. Material Forming: ESAFORM 2025, 68 – 77, Materials Research Forum LLC. doi:10.21741/9781644903599-8

FRÖLICH, F.; Dörr, D.; Jackstadt, A.; Wittemann, F.; Kärger, L.

2025. Material Forming - ESAFORM 2025, 2281–2290, Materials Research Forum LLC. doi:10.21741/9781644903599-246

Frölich, F.; Hof, L.; Zimmerling, C.; Wittemann, F.; Kärger, L.

2024. The International Journal of Advanced Manufacturing Technology. doi:10.1007/s00170-024-14913-w

Knirsch, J.; Frölich, F.; Hof, L.; Wittemann, F.; Kärger, L.

2024. Journal of Open Source Software, 9 (99), Art.-Nr.: 6465. doi:10.21105/joss.06465

Hof, L.; Frölich, F.; Wittemann, F.; Kärger, L.

2024, July 2. 21st European Conference on Composite Materials (ECCM 2024), Nantes, France, July 2–5, 2024

Frölich, F.; Bechtloff, L.; Scheuring, B. M.; Heuer, A. L.; Wittemann, F.; Kärger, L.; Liebig, W. V.

2025. Progress in Additive Manufacturing, 10 (2), 1217–1229. doi:10.1007/s40964-024-00700-2

Di Nardo, M. E.; Frölich, F.; Kärger, L.; Carlone, P.

2024. Material Forming: ESAFORM 2024, 603–612, Materials Research Forum LLC. doi:10.21741/9781644903131-67

Frölich, F.; Bechtloff, L.; Scheuring, B. M.; Heuer, A.; Kärger, L.; Liebig, W. V.

2023, August 3. 23rd International Conference on Composite Materials (ICCM 2023), Belfast, United Kingdom, July 30–August 4, 2023

Frölich, F.; Kärger, L.

2022. Key Engineering Materials, 926, 331–340. doi:10.4028/p-uq57va

Frölich, F.; Dörr, D.; Jackstadt, A.; Kärger, L.

2022, July 4. 11th European Solid Mechanics Conference (2022), Galway, Ireland, July 4–8, 2022

Englert, L.; Heuer, A.; Engelskirchen, M. K.; Frölich, F.; Dietrich, S.; Liebig, W. V.; Kärger, L.; Schulze, V.

2022. Virtual and Physical Prototyping, 17 (3), 508–527. doi:10.1080/17452759.2022.2048228