Compression molding (SMC/LFT)

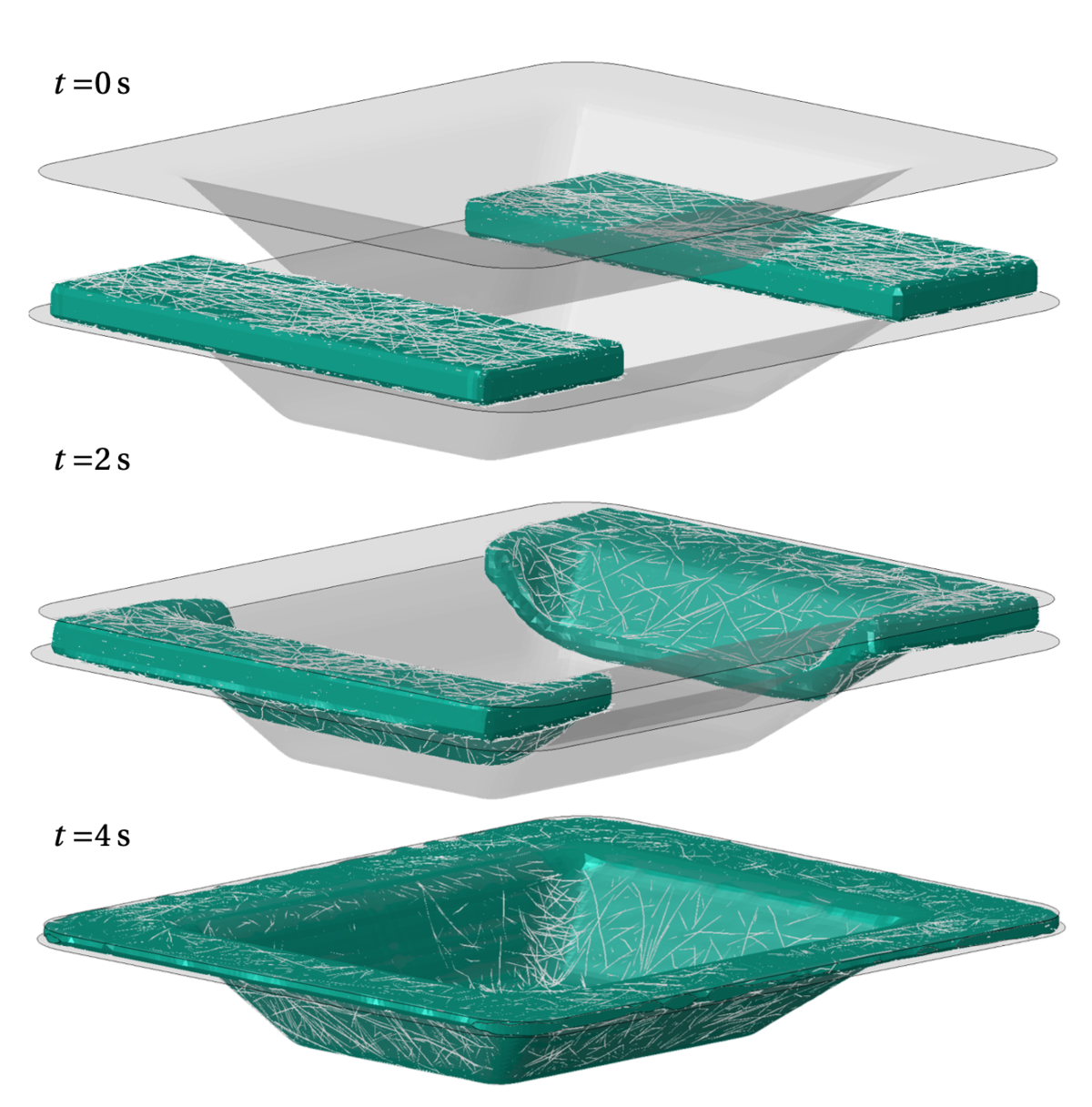

The simulation of the compression molding process of discontinuous reinforced polymer aims at describing the mold filling of a moving mold cavity. We focus on the manufacturing process of long fiber reinforced thermoplastics (LFT) and sheet molding compound (SMC). In these simulations, the flow process is considered taking into account process parameters and material properties. As a result, the filling state, fiber orientation and process forces are predicted.

Research focus

- Modeling anisotropic flow

- Direct Bundle Simulation for a precise prediction of the fiber architecture

- Direct simulation of fiber suspensions for parameterisation of macroscopic fiber suspensions

- Process optimization

- Warpage simulation

Research projects |

Contact

|

Selected publications in the research field

Evaluation of the informed isotropic (IISO) viscosity model for compression molding of discontinuous fiber reinforced polymers

Schreyer, L.; Krauß, C.; Wittemann, F.; Kärger, L.

2026. Composites Part A: Applied Science and Manufacturing, 203, 109552. doi:10.1016/j.compositesa.2025.109552

Schreyer, L.; Krauß, C.; Wittemann, F.; Kärger, L.

2026. Composites Part A: Applied Science and Manufacturing, 203, 109552. doi:10.1016/j.compositesa.2025.109552

The first European benchmark exercise on squeeze flow testing of high-performance carbon fibre sheet moulding compounds

Qian, C.; Duhovic, M.; Schommer, D.; Gortner, F.; Gebhard, A.; Neumeyer, T.; Olma, M.; Schreyer, L.; Kärger, L.; Hohberg, M.; Yuan, H.; Imbsweiler, A. J.; Ramirez, L. S.; Simaafrookhteh, S.; Ivens, J.; Lomov, S. V.; Bieleman, G.; Grouve, W.; Mahé, F.; Binetruy, C.; Kapshammer, A.; Major, Z.; Ivanov, D. S.; Belnoue, J. P.-H.; Koptelov, A.; Jakimow, J.; Aitomaki, Y.; Ramantani, D.

2025. Material Forming: ESAFORM 2025. Ed.: P. Carlone, 676 – 685, Materials Research Forum LLC. doi:10.21741/9781644903599-73

Qian, C.; Duhovic, M.; Schommer, D.; Gortner, F.; Gebhard, A.; Neumeyer, T.; Olma, M.; Schreyer, L.; Kärger, L.; Hohberg, M.; Yuan, H.; Imbsweiler, A. J.; Ramirez, L. S.; Simaafrookhteh, S.; Ivens, J.; Lomov, S. V.; Bieleman, G.; Grouve, W.; Mahé, F.; Binetruy, C.; Kapshammer, A.; Major, Z.; Ivanov, D. S.; Belnoue, J. P.-H.; Koptelov, A.; Jakimow, J.; Aitomaki, Y.; Ramantani, D.

2025. Material Forming: ESAFORM 2025. Ed.: P. Carlone, 676 – 685, Materials Research Forum LLC. doi:10.21741/9781644903599-73

Process-induced skewness of flow fronts and fiber orientations in LFT-D compression molding considering processing, characterization, and simulation

Schelleis, C.; Scheuring, B. M.; Schreyer, L.; Liebig, W. V.; Hrymak, A.; Kärger, L.; Weidenmann, K. A.; Henning, F.

2025. Journal of Thermoplastic Composite Materials, 38 (8), 2922–2944. doi:10.1177/08927057251344252

Schelleis, C.; Scheuring, B. M.; Schreyer, L.; Liebig, W. V.; Hrymak, A.; Kärger, L.; Weidenmann, K. A.; Henning, F.

2025. Journal of Thermoplastic Composite Materials, 38 (8), 2922–2944. doi:10.1177/08927057251344252

Characterization and modeling of the anisotropic flow behavior of long carbon fiber reinforced thermoplastic compression molding

Schreyer, L.; Krauß, C.; Scheuring, B. M.; Hrymak, A.; Kärger, L.

2025. Composites Part A: Applied Science and Manufacturing, 198, Articlen no: 109053. doi:10.1016/j.compositesa.2025.109053

Schreyer, L.; Krauß, C.; Scheuring, B. M.; Hrymak, A.; Kärger, L.

2025. Composites Part A: Applied Science and Manufacturing, 198, Articlen no: 109053. doi:10.1016/j.compositesa.2025.109053

Experimental investigation to reduce knit line effects in C-SMC

Olma, M.; Meyer, N.; Ilinzeer, S.; Krauß, C.; Wittemann, F.; Kärger, L.

2025. Material Forming: ESAFORM 2025, 355–362, Materials Research Forum LLC. doi:10.21741/9781644903599-39

Olma, M.; Meyer, N.; Ilinzeer, S.; Krauß, C.; Wittemann, F.; Kärger, L.

2025. Material Forming: ESAFORM 2025, 355–362, Materials Research Forum LLC. doi:10.21741/9781644903599-39

Micro-scale flow simulations for determination of interaction coefficients in macroscopic fibre orientation modelling

Wittemann, F.; Hof, L.; Meyer, N.; Kärger, L.

2025, April 9. 14th International Conference on Manufacturing of Advanced Composites (ICMAC 2025), Coventry, United Kingdom, April 9–10, 2025

Wittemann, F.; Hof, L.; Meyer, N.; Kärger, L.

2025, April 9. 14th International Conference on Manufacturing of Advanced Composites (ICMAC 2025), Coventry, United Kingdom, April 9–10, 2025

Initial stack placement strategies for carbon fiber- reinforced sheet molding compound (C-SMC)

Olma, M.; Meyer, N.; Krauß, C.; Wittemann, F.; Kärger, L.

2024, July 5. 21st European Conference on Composite Materials (ECCM 2024), Nantes, France, July 2–5, 2024

Olma, M.; Meyer, N.; Krauß, C.; Wittemann, F.; Kärger, L.

2024, July 5. 21st European Conference on Composite Materials (ECCM 2024), Nantes, France, July 2–5, 2024

Rheological characterization and macroscopic modeling and simulation of the molding process of a PA6 Glass Mat Thermoplastic (GMT)

Dörr, D.; Singh-Heer, N.; Gergely, R. C. R.; Schreyer, L.; Henning, F.; Straatman, A. G.; Hrymak, A.

2024. Composites Part A: Applied Science and Manufacturing, 176, Art.-Nr. 107780. doi:10.1016/j.compositesa.2023.107780

Dörr, D.; Singh-Heer, N.; Gergely, R. C. R.; Schreyer, L.; Henning, F.; Straatman, A. G.; Hrymak, A.

2024. Composites Part A: Applied Science and Manufacturing, 176, Art.-Nr. 107780. doi:10.1016/j.compositesa.2023.107780

Continuous Simulation of a Continuous-Discontinuous Fiber Reinforced Thermoplastic (CoDiCoFRTP) Compression Molding Process

Schreyer, L.; Scheuring, B. M.; Christ, N.; Blarr, J.; Krauß, C.; Liebig, W. V.; Weidenmann, K. A.; Böhlke, T.; Hrymak, A.; Kärger, L.

2024. Proceedings of the 2023 International Conference on Composite Materials, Belfast, 30th July - 4th August 2023, Queen’s University Belfast

Schreyer, L.; Scheuring, B. M.; Christ, N.; Blarr, J.; Krauß, C.; Liebig, W. V.; Weidenmann, K. A.; Böhlke, T.; Hrymak, A.; Kärger, L.

2024. Proceedings of the 2023 International Conference on Composite Materials, Belfast, 30th July - 4th August 2023, Queen’s University Belfast

Generation of Initial Fiber Orientation States for Long Fiber Reinforced Thermoplastic Compression Molding Simulation

Schreyer, L.; Blarr, J.; Höger, K.; Meyer, N.; Kärger, L.

2022. Composites Meet Sustainability : Proceedings of the 20th European Conference on Composite Materials, ECCM20. 26-30 June, 2022, Lausanne, Switzerland. Bd.: 4. Ed.: A. Vassilopoulos, 687–694, École Polytechnique Fédérale de Lausanne (EPFL)

Schreyer, L.; Blarr, J.; Höger, K.; Meyer, N.; Kärger, L.

2022. Composites Meet Sustainability : Proceedings of the 20th European Conference on Composite Materials, ECCM20. 26-30 June, 2022, Lausanne, Switzerland. Bd.: 4. Ed.: A. Vassilopoulos, 687–694, École Polytechnique Fédérale de Lausanne (EPFL)

A probabilistic virtual process chain to quantify process-induced uncertainties in Sheet Molding Compounds

Meyer, N.; Gajek, S.; Görthofer, J.; Hrymak, A.; Kärger, L.; Henning, F.; Schneider, M.; Böhlke, T.

2022. doi:10.48550/arXiv.2209.05873

Meyer, N.; Gajek, S.; Görthofer, J.; Hrymak, A.; Kärger, L.; Henning, F.; Schneider, M.; Böhlke, T.

2022. doi:10.48550/arXiv.2209.05873

A probabilistic virtual process chain to quantify process-induced uncertainties in Sheet Molding Compounds

Meyer, N.; Gajek, S.; Görthofer, J.; Hrymak, A.; Kärger, L.; Henning, F.; Schneider, M.; Böhlke, T.

2023. Composites Part B: Engineering, 249, Art.-Nr.: 110380. doi:10.1016/j.compositesb.2022.110380

Meyer, N.; Gajek, S.; Görthofer, J.; Hrymak, A.; Kärger, L.; Henning, F.; Schneider, M.; Böhlke, T.

2023. Composites Part B: Engineering, 249, Art.-Nr.: 110380. doi:10.1016/j.compositesb.2022.110380

Probabilistic virtual process chain for process-induced uncertainties in fiber-reinforced composites

Meyer, N.; Gajek, S.; Görthofer, J.; Hrymak, A.; Luise Kärger; Henning, F.; Schneider, M.; Böhlke, T.

2022, September 19. MATHSEE Workshop "Multiscale Effects in Mechanics Under Uncertainty Considerations" (2022), Karlsruhe, Germany, September 19, 2022

Meyer, N.; Gajek, S.; Görthofer, J.; Hrymak, A.; Luise Kärger; Henning, F.; Schneider, M.; Böhlke, T.

2022, September 19. MATHSEE Workshop "Multiscale Effects in Mechanics Under Uncertainty Considerations" (2022), Karlsruhe, Germany, September 19, 2022

A Benchmark for Fluid-Structure Interaction in Hybrid Manufacturing: Coupled Eulerian-Lagrangian Simulation

Meyer, N.; Werner, H. O.; Seuffert, J.; Dietrich, S.; Poppe, C.; Krauß, C.; Kärger, L.

2021, July 21. 5th International Conference on Hybrid Materials and Structures (2022), Leoben, Austria, July 20–22, 2022

Meyer, N.; Werner, H. O.; Seuffert, J.; Dietrich, S.; Poppe, C.; Krauß, C.; Kärger, L.

2021, July 21. 5th International Conference on Hybrid Materials and Structures (2022), Leoben, Austria, July 20–22, 2022

A Benchmark for Fluid-Structure-Interaction in Hybrid Manufacturing: Simulation with preCICE in OpenFOAM

Dietrich, S.; Seuffert, J.; Werner, H.; Meyer, N.; Poppe, C.; Krauß, C.; Kärger, L.

2022, June 9. 8th European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2022), Oslo, Norway, June 5–9, 2022

Dietrich, S.; Seuffert, J.; Werner, H.; Meyer, N.; Poppe, C.; Krauß, C.; Kärger, L.

2022, June 9. 8th European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2022), Oslo, Norway, June 5–9, 2022

Manufacturing Simulation of Sheet Molding Compound (SMC)

Revfi, S.; Albers, A.; Meyer, N.; Kärger, L.; Schöttl, L.; Bartkowiak, M.; Behdinan, K.

2021. NAFEMS World Congress (NWC 2021)

Revfi, S.; Albers, A.; Meyer, N.; Kärger, L.; Schöttl, L.; Bartkowiak, M.; Behdinan, K.

2021. NAFEMS World Congress (NWC 2021)

Material and particle size sensitivity analysis on coefficient of restitution in low-velocity normal impacts

Meyer, N.; Wagemann, E. L.; Jackstadt, A.; Seifried, R.

2022. Computational Particle Mechanics, 9 (6), 1293–1308. doi:10.1007/s40571-022-00471-z

Meyer, N.; Wagemann, E. L.; Jackstadt, A.; Seifried, R.

2022. Computational Particle Mechanics, 9 (6), 1293–1308. doi:10.1007/s40571-022-00471-z

Mesoscale simulation of the mold filling process of Sheet Molding Compound. PhD dissertation

Meyer, N.

2022. KIT Scientific Publishing. doi:10.5445/KSP/1000143703

Meyer, N.

2022. KIT Scientific Publishing. doi:10.5445/KSP/1000143703

Experimental and Numerical Analysis of SMC Compression Molding in Confined Regions : A Comparison of Simulation Approaches

Rothenhäusler, F.; Meyer, N.; Wehler, S.; Hohberg, M.; Gude, M.; Henning, F.; Kärger, L.

2022. Journal of composites science, 6 (3), Art.-Nr.: 68. doi:10.3390/jcs6030068

Rothenhäusler, F.; Meyer, N.; Wehler, S.; Hohberg, M.; Gude, M.; Henning, F.; Kärger, L.

2022. Journal of composites science, 6 (3), Art.-Nr.: 68. doi:10.3390/jcs6030068

A sequential approach for simulation of thermoforming and squeeze flow of glass mat thermoplastics

Dörr, D.; Ivanov, S.; Gergely, R.; Meyer, N.; Henning, F.; Straatman, A. G.; Hrymak, A.

2021. ESAFORM 2021: 24th International Conference on Material Forming ; 14-16 April 2021, online, Art.-Nr.: 376, Université de Liège. doi:10.25518/esaform21.376

Dörr, D.; Ivanov, S.; Gergely, R.; Meyer, N.; Henning, F.; Straatman, A. G.; Hrymak, A.

2021. ESAFORM 2021: 24th International Conference on Material Forming ; 14-16 April 2021, online, Art.-Nr.: 376, Université de Liège. doi:10.25518/esaform21.376

Mesoscale simulation of the mold filling process of Sheet Molding Compound. PhD dissertation

Meyer, N.

2021, October 15. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000138778

Meyer, N.

2021, October 15. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000138778

Modeling Short-Range Interactions in Concentrated Newtonian Fiber Bundle Suspensions

Meyer, N.; Hrymak, A. N.; Kärger, L.

2021. International Polymer Processing, 36 (3), 255–263. doi:10.1515/ipp-2020-4051

Meyer, N.; Hrymak, A. N.; Kärger, L.

2021. International Polymer Processing, 36 (3), 255–263. doi:10.1515/ipp-2020-4051

Parameter Identification of Fiber Orientation Models Based on Direct Fiber Simulation with Smoothed Particle Hydrodynamics

Meyer, N.; Saburow, O.; Hohberg, M.; Hrymak, A. N.; Henning, F.; Kärger, L.

2020. Journal of composites science, 4 (2), 77. doi:10.3390/jcs4020077

Meyer, N.; Saburow, O.; Hohberg, M.; Hrymak, A. N.; Henning, F.; Kärger, L.

2020. Journal of composites science, 4 (2), 77. doi:10.3390/jcs4020077

Direct Bundle Simulation approach for the compression molding process of Sheet Molding Compound

Meyer, N.; Schöttl, L.; Bretz, L.; Hrymak, A. N.; Kärger, L.

2020. Composites / A, 132, Article: 105809. doi:10.1016/j.compositesa.2020.105809

Meyer, N.; Schöttl, L.; Bretz, L.; Hrymak, A. N.; Kärger, L.

2020. Composites / A, 132, Article: 105809. doi:10.1016/j.compositesa.2020.105809

A revisit of Jeffery‘s equation - modelling fiber suspensions with Smoothed Particle Hydrodynamics

Meyer, N.; Saburow, O.; Hohberg, M.; Hrymak, A.; Henning, F.; Kärger, L.

2018, September 27. Materials Science and Engineering Congress (MSE 2018), Darmstadt, Germany, September 26–28, 2018

Meyer, N.; Saburow, O.; Hohberg, M.; Hrymak, A.; Henning, F.; Kärger, L.

2018, September 27. Materials Science and Engineering Congress (MSE 2018), Darmstadt, Germany, September 26–28, 2018

Virtual process chain of sheet molding compound: Development, validation and perspectives

Görthofer, J.; Meyer, N.; Pallicity, T. D.; Schöttl, L.; Trauth, A.; Schemmann, M.; Hohberg, M.; Pinter, P.; Elsner, P.; Henning, F.; Hrymak, A.; Seelig, T.; Weidenmann, K.; Kärger, L.; Böhlke, T.

2019. Composites / B, 169, 133–147. doi:10.1016/j.compositesb.2019.04.001

Görthofer, J.; Meyer, N.; Pallicity, T. D.; Schöttl, L.; Trauth, A.; Schemmann, M.; Hohberg, M.; Pinter, P.; Elsner, P.; Henning, F.; Hrymak, A.; Seelig, T.; Weidenmann, K.; Kärger, L.; Böhlke, T.

2019. Composites / B, 169, 133–147. doi:10.1016/j.compositesb.2019.04.001