WAK-Awards 2024

October 2024: Once a year, the “Wissenschaftlicher Arbeitskreis Kunststofftechnik (WAK)” acknowledges the best scientific works in the field of plastics technology. The prizes are provided by four innovative companies in the plastics technology sector. In the areas of materials, design, processing, and recycling, the best master’s thesis and dissertation are awarded.

This year, the WAK awarded the Wilfried Ensinger Prize to M. Sc. Christina Dohmen for her master's thesis in the field of development and description of engineering plastics for innovative applications. Ms Dohmen's thesis entitled "Transversalisotropic, thermoviscoelastic modelling and characterization of a closed-cell polymer structural foam" was supervised by M. Sc. Sarah Schlegel, Prof. Dr.-Ing. Luise Kärger and Prof. Dr.-Ing. Frank Henning.

Dr.-Ing. Constantin Krauß receives the WAK's Oechsler Prize for his dissertation for the best work in the field of methods and approaches for the development and design of plastic components. Mr. Krauß' thesis entitled "Direction-dependent result data transfer in virtual process chains for fiber-reinforced polymers and the impact on structural simulation" was supervised by Prof. Dr.-Ing. Luise Kärger.

The WAK awards the Brose Prize for Dr. Bastian Schäfer's dissertation for the best work in the field of new processes and techniques in plastics processing. Mr. Schäfer's thesis entitled "Macroscopic forming simulation of unidirectional non-crimp fabrics: Hyperelastic material modeling and 3D-solid-shell approach" was supervised by Prof. Dr.-Ing. Luise Kärger and Prof. Dr.-Ing. Frank Henning.

SAMPE Germany Innovation Award and SAMPE Europe "Best PhD" Award

October 2023: Every year, SAMPE Europe awards a prize for the best doctoral thesis in the field of fibre composites and we are delighted to announce that Clemens Zimmerling has won the prize! Clemens' thesis had already been selected as a representative for SAMPE Germany in the national competition and now had to face the international competition.

The jury of international experts did not have it easy: 16 student candidates from Finland to Spain presented their excellent research work on new materials and innovative processes to the international panel of experts. We are delighted that Clemens was able to impress the international jury with his doctoral thesis on AI-supported process optimisation.

ESAFORM PhD Prize 2023 for Industrial Research

April 2023: For the twelfth time, the European Scientific Association for Material Forming (ESAFORM) is honouring outstanding dissertations in the field of material forming at the annual ESAFORM conference. This year, ESAFORM is honouring the dissertation by Dr Clemens Zimmerling from KIT-FAST with the Lionel Fourment ESAFORM Phd Prize for Industrial Research 2023.

After Dr Dominik Dörr and Dr Christian Poppe, Dr Clemens Zimmerling was able to convince the jury this year. This is the third time in a row that the prize has gone to FAST! Following the award ceremony, Clemens was able to present his work on ML-assisted process engineering to the audience. We are delighted that Clemens' work has been recognised!

Dr.-Ing. Höfler award of the Faculty of Mechanical Engineering

July 2023: The KIT Faculty of Mechanical Engineering awards Lukas Hof and Jan Paul Wank the Dr.-Ing. Willy-Höfler Prize for their Master's theses.

Lukas Hof wins the prize in the subject area "Materials Engineering". His Master's thesis was written under the supervision of Prof. Dr.-Ing. Luise Kärger and M. Sc. Felix Fröhlich and is entitled "Development of a simulation model for strand deposition in material extrusion using the smoothed particle hydrodynamics method". Jan Paul Wank is awarded the prize in the category "Thermodynamics". His Master's thesis was supervised by Prof. Dr.-Ing. Luise Kärger and M. Sc. Louis Schreyer and is entitled "Development of an efficient simulation model for the extrusion of long-fibre reinforced thermoplastics".

The prizes are donated by the Dr.-Ing. Willy-Höfler Foundation and awarded annually during the Mechanical Engineering Day.

Dr.-Ing. Höfler award of the Faculty of Mechanical Engineering

Nils Meyer wins the Dr.-Ing. Höfler award for the best doctoral thesis in mechanical engineering 2021

The Faculty of Mechanical Engineering at KIT awards the Dr.-Ing. Höfler award for the best doctoral thesis in mechanical engineering 2021 to Nils Meyer from the Institute of Vehicle System technology – Lightweight Design. The prize was donated by the Dr.-Ing. Willy-Höfler-Foundation and is awarded once a year. At the ceremony, Nils Meyer gave a short and very comprehensible presentation of his research.

ESAFORM Phd Prize 2022 for Industrial Research

April 2022: For the eleventh time, the European Scientific Association for Material Forming (ESAFORM) honors dissertations with an outstanding contribution in the field of industrial material forming at the annual ESAFORM conference. This year, ESAFORM honors the dissertation of Dr.-Ing. Christian Poppe from KIT-FAST with the Lionel Fourment ESAFORM Ph.D. Prize for Industrial Research 2022.

With his simulation model for the wet pressing technology of continuous fiber-reinforced structural components, Dr.-Ing. Christian Poppe has succeeded for the first time in describing the forming of semi-finished products and their infiltration during the process simultaneously in one model. This makes it possible to advance forward-looking topics in the fields of lightweight construction and software-defined manufacturing, which are important for mobility. Thanks to his work, new software modules are now available that support resource-saving process design of lightweight structures and are used in the automotive and aerospace industries for product development.

WAK / Röchling Prize 2021 for an outstanding master thesis

For the 20th time, the Scientific Working Group of University Professors of Plastics Engineering (WAK) honors the best scientific theses in the field of plastics engineering. Eight prizes were offered in the three categories of materials, design and processing, as well as the special prize for hybrids. The WAK awarded the master thesis of M.Sc. Felix Frölich from KIT-FAST with the Röchling Prize for the best master´s thesis in the field of new hybrid materials, systems and process technologies based on plastics.

The thesis entitled "Modelling and numerical investigation of the Mullins effect regarding the damping behavior of hybrid CFRP-elastomer-metal laminates" was written under the supervision of Prof. Dr.-Ing. Luise Kärger as well as M.Sc. Alexander Jackstadt.

SAMPE Deutschland Innovationspreis 2021

SAMPE Germany awards the Innovation Prize for outstanding theses to Louis Schreyer from the Lightweight Construction Technology department. His master's thesis was written under the supervision of Prof. Dr.-Ing. Luise Kärger and M.Sc. Constantin Krauß and is entitled "Numerical impact analysis of high-pressure accumulators in fiber composite construction using the finite element method".

ESAFORM Phd Prize for Industrial Research

April 2021: For the tenth time, the European Scientific Association for Material Forming (ESAFORM) honors dissertations with an outstanding contribution in the field of industrial material forming at the annual ESAFORM conference. This year, ESAFORM honors the dissertation of Dr.-Ing. Dominik Dörr from KIT-FAST with the Lionel Fourment ESAFORM Phd Prize for Industrial Research 2021.

With the simulation of the forming process of thermoplastic tape laminates, Dominik Dörr dedicated himself to a forward-looking topic in the fields of lightweight construction and software-defined manufacturing, which are important for mobility. Thanks to his work, new software modules are now available that support resource-saving process design of lightweight structures and are used in the automotive and aerospace industries for product development.

WAK / Röchling Prize 2020 for outstanding dissertation

November 2020:

The Scientific Working Group of University Professors of Plastics Engineering (WAK) is awarding prizes for the best scientific papers in the field of plastics engineering for the 19th time. Eight prizes were awarded in the three categories of materials, design and processing, as well as the special prize for hybrids. WAK honored the dissertation of Dr.-Ing. Dominik Dörr of KIT-FAST with the Röchling Prize for the best dissertation in the field of new hybrid materials, systems, and process technologies based on plastics.

With the simulation of the forming process of thermoplastic tape laminates, Dominik Dörr dedicated himself to a forward-looking topic in the fields of lightweight construction and software-defined manufacturing, which are important for mobility. Thanks to his work, new software modules are now available that support resource-saving process design of lightweight structures and are used in the automotive and aerospace industries for product development.

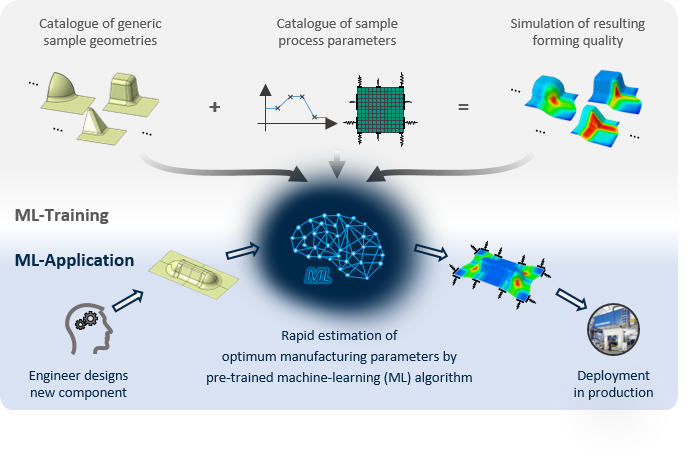

ESAFORM „Best Communication Award“ in bronze

The European Scientific Association for Material Forming (ESAFORM) honours Clemens Zimmerling (KIT-FAST) with the Best Communication Award in bronze. The paper awarded by the jury, discusses possible applications of machine learning methods for time-efficient optimisation of textile forming processes. The prize was established in 2020 and is intended to help make innovative work by young scientists in the field of material forming more visible internationally.

Figure: Schematic sketch of the envisioned application of machine-learning techniques for time-efficient proces optimisation

ThinKing – Lightweight idea of the month

Is this envisioned component truly manufacturable with this proposed geometry? Precise manufacturing simulations give an answer, but are often time-consuming. A new software idea from KIT may speed up this proces: The scientists combine process simulations with machine learning and AI techniques so that an algorithm recognizes component features and quickly assesses if production of the component will work satisfactory. This saves costs in development and production.

With a wink, the scientists call it "virtual AI process expert". "It's almost like assembling the know-how and intuition of many engineers into one program and making it available at the touch of a button," explains Clemens Zimmerling from the Institute of Vehicle Systems Engineering at the Karlsruhe Institute of Technology (KIT). This virtual process expert is to be used in the design of lightweight structures made of fiber composites - both to quickly optimize the component and its manufacturing process.

Figure: Schematic sketch of the envisioned application of machine-learning techniques for time-efficient proces optimisation

Redtenbacher Prize of the Faculty of Mechanical Engineering at KIT

Nils Meyer wins the Redtenbacher Prize for the best Master's degree in mechanical engineering 2017

July 2018: The Faculty of Mechanical Engineering at KIT awards the Redtenbacher Prize for the best Master's degree in Mechanical Engineering 2017 to Nils Meyer from the Institute for Lightweight Technology.

The prize was donated by the KSB Foundation and is complemented by a medal engraved with Redtenbacher's portrait.

Ferdinand Redtenbacher (1809-1863) is considered a pioneer of scientific mechanical engineering and taught at the Karlsruhe Polytechnic until shortly before his death.

Dean of the Faculty of Mechanical Engineering Prof. Dr.-Ing. Carsten Proppe and award winner Nils Meyer

Hanns-Voith-Foundation Award

Juni 2018: For the Sixth time in history, the Hanns-Voith-Foundation honors outstanding final theses by awarding a foundation prize. Constantin Krauß from the Institut of Lightweight Technology was honored in the "New Materials" thematic cluster. His master's thesis was conducted under the supervision of Prof. Dr.-Ing. Frank Henning and Dipl.-Ing. David Hummelberger and is entitled "Development and validation of a mechanism-based design methodology for metal-metal hybrids"

left to right: Project lead Dipl.-Ing. David Hummelberger, Award winner Constantin Krauß, Supervisor Prof. Dr.-Ing. Frank Henning, Dr. Johannes Staeves (BMW Group)

Project "SMiLE" awarded as lighthouse project

June 2015: On the occasion of the National Conference on Electromobility on June 15 and 16 in Berlin, the German government has designated seven outstanding technological projects as lighthouses of electromobility. The selection of a project as a lighthouse is a "seal of approval" for particularly important innovations that make a significant contribution to technological progress or cost reduction in electromobility. The lighthouses selected to date have focused on six future fields:

- Drive systems

- Energy systems and energy storage

- Charging infrastructure and grid integration, mobility concepts

- Recycling and resource efficiency

- information and communication technology and

- Lightweight construction

SMiLE's goal is to develop a lightweight construction concept that is fully adapted to the special requirements of electromobility. The structure of the project ensures that the results are directly incorporated into standardizable products at the manufacturers along the value chain. The starting point are innovative materials and manufacturing processes adapted to their properties, which in conjunction with novel concepts provide the basis for competitive products.

The project is funded by the German Federal Ministry of Education and Research (BMBF).

source: bmbf.de (01.07.2015)

AVK Innovationspreis

October 2014: Presentation of the AVK Innovation Award in Frankfurt am Main

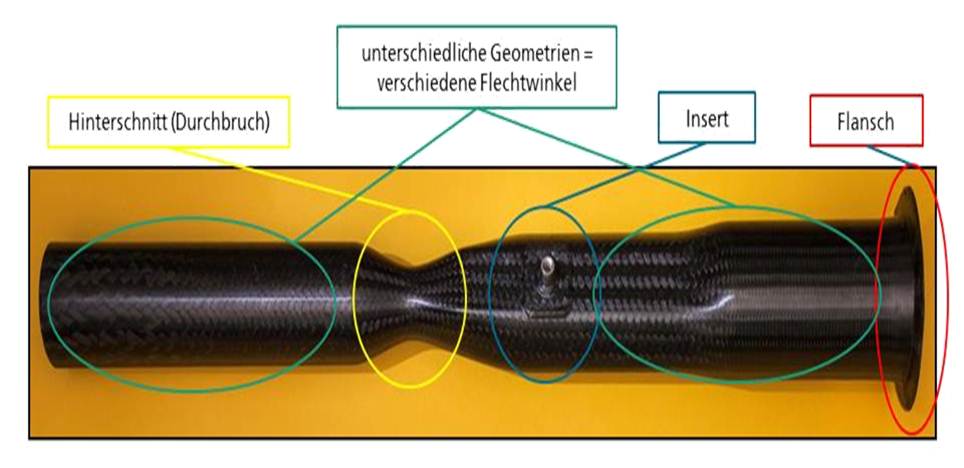

Integral fabrication of a functionally integrated structural hollow component by means of triaxial braiding in a high pressure RTM process

The demonstrator realized in the project "Research for a closed simulation and manufacturing process chain for crash-relevant fiber composite structures in automotive engineering" is a generic structural hollow component (derived from a seat cross member), which was manufactured with a tri-axial braid in combination with a high-pressure RTM process. From a manufacturing point of view, the focus was on an integral production with cycle times below 5 min. In the demonstrator, the following production engineering challenges were mastered:

- Display of continuously varying cross-sections along the length of the component for defined energy absorption

- Integration of an insert for load/force application

- Realization of an undercut in the component (e.g. for cable bushings)

- Production of a flange for possible connection to other components

Hanns-Voith-Foundation Award

Juni 2014: For the second time in its history, the Hanns-Voith-Foundation honors outstanding final theses by awarding a foundation prize. This year, a graduate from the Institut of Lightweight Technology at KIT was was honored in the “New Materials” thematic cluster. Alexander Bernath receives the award for his diploma thesis entitled "Development of a method for simulating resin transfer molding with OpenFOAM".

Vector Stiftungs-YIG „Green Mobility“

Frau Dr.-Ing. Luise Kärger wurde die Leitung einer neuen Young Investigator Group (YIG) übertragen, die das KIT in Kooperation mit der Vector Stiftung eingerichtet hat. YIGs dienen der Förderung herausragender Nachwuchswissenschaftler nach Abschluss der Promotion, ihrer frühen Selbständigkeit und der Stärkung des Forschungsprofils des KIT. Mit der YIG erhielt Frau Dr. Kärger den offiziellen Status einer Nachwuchsgruppenleiterin und wurde Mitglied im Young Investigator Network (YIN), dem interdisziplinären Forschungsnetzwerk der unabhängigen Nachwuchsgruppenleiter des KIT.