RTM mold filling

The aim in simulating the mold filling process is to predict the course of the resin flow front in order to minimize process time or cavity pressure and to avoid dry spots.

The simulations are carried out using specially developed methods based on OpenFOAM®.

Emphasis is placed on the component-level simulation of complex RTM process variants as well as the flow around embedded load introduction elements.

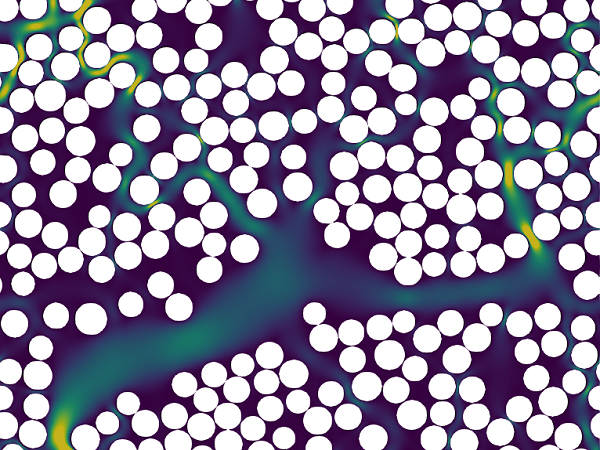

In addition to the experimental measurement of material parameters (permeability of the semi-finished product, viscosity of the resin), another focus is the numerical determination of permeability by homogenization of the fiber flow around at micro and meso level.

Research focus

-

Component-level simulation of complex RTM process variants such as pressure-controlled RTM (PC-RTM)

-

Simulation of mold filling during the production of sandwich components

-

Simulation of the flow around embedded load introduction elements

-

Numerical determination of the semi-finished product permeability by homogenization of the flow behavior on micro and meso level

Research projects |

Contact

Tel.: +49 721 608-41816

Email: sarah.schlegel∂kit.edu

Tel.: +49 721 608-45383

Email: dennis.weitze∂kit.edu

|

Selected publications in the research field

Lasttragende FVK-Metall-Hybridstruktur für automobile Crashanwendungen

Muth, M.; Seuffert, J.; Bernath, A.; Roth, S.; Weidenmann, K.

2019. 23. Internationales Dresdner Leichtbausymposium (2019), Dresden, Germany, June 27–28, 2019

Muth, M.; Seuffert, J.; Bernath, A.; Roth, S.; Weidenmann, K.

2019. 23. Internationales Dresdner Leichtbausymposium (2019), Dresden, Germany, June 27–28, 2019

Investigation of the thermoviscoelastic behavior of a closed-cell polymer structural foam under pressure for processing in hybrid LCM processes

Dietrich, S.; Dohmen, C.; Frölich, F.; Jackstadt, A.; Wittemann, F.; Kärger, L.

2024. Proceedings of the 21st European Conference on Composite Materials. Vol 2 Material Science. Ed.: C. Binetruy, 548–554, European Society for Composite Materials (ESCM)

Dietrich, S.; Dohmen, C.; Frölich, F.; Jackstadt, A.; Wittemann, F.; Kärger, L.

2024. Proceedings of the 21st European Conference on Composite Materials. Vol 2 Material Science. Ed.: C. Binetruy, 548–554, European Society for Composite Materials (ESCM)

of-rtm-6 – An OpenFOAM-6 extension with curing models and anisotropic permeability for usage in LCM simulations

Bernath, A.; Seuffert, J.; Dietrich, S.; Poppe, N.; Magagnato, D.; Wittemann, F.; Henning, F.; Kärger, L.

2024. doi:10.5281/zenodo.13327698

Bernath, A.; Seuffert, J.; Dietrich, S.; Poppe, N.; Magagnato, D.; Wittemann, F.; Henning, F.; Kärger, L.

2024. doi:10.5281/zenodo.13327698

Multiscale behavior of locally reinforced composite structures produced by tailored fiber placement

Bittrich, L.; Lisboa, T.; Uhlig, K.; Dietrich, S.; Kärger, L.; Stommel, M.; Spickenheuer, A.

2023. 23rd International Conference on Composite Materials, ICCM 2023 : Belfast, 30th July - 4th August 2023, International Committee on Composite Materials

Bittrich, L.; Lisboa, T.; Uhlig, K.; Dietrich, S.; Kärger, L.; Stommel, M.; Spickenheuer, A.

2023. 23rd International Conference on Composite Materials, ICCM 2023 : Belfast, 30th July - 4th August 2023, International Committee on Composite Materials

Numerical Investigation of the Mold Filling Behavior of Sandwich Parts in Resin Transfer Molding

Dietrich, S.; Seuffert, J.; Kärger, L.

2023. 23rd International Conference on Composite Materials (ICCM 2023), 8 S., Queen’s University Belfast

Dietrich, S.; Seuffert, J.; Kärger, L.

2023. 23rd International Conference on Composite Materials (ICCM 2023), 8 S., Queen’s University Belfast

On the Resin Transfer Molding (RTM) Infiltration of Fiber-Reinforced Composites made by Tailored Fiber Placement

Bittrich, L.; Seuffert, J.; Dietrich, S.; Uhlig, K.; Lisboa, T. de V.; Kärger, L.; Spickenheuer, A.

2022. Polymers, 14 (22), Art.-Nr.: 4873. doi:10.3390/polym14224873

Bittrich, L.; Seuffert, J.; Dietrich, S.; Uhlig, K.; Lisboa, T. de V.; Kärger, L.; Spickenheuer, A.

2022. Polymers, 14 (22), Art.-Nr.: 4873. doi:10.3390/polym14224873

A Benchmark for Fluid-Structure Interaction in Hybrid Manufacturing: Coupled Eulerian-Lagrangian Simulation

Meyer, N.; Werner, H. O.; Seuffert, J.; Dietrich, S.; Poppe, C.; Krauß, C.; Kärger, L.

2021, July 21. 5th International Conference on Hybrid Materials and Structures (2022), Leoben, Austria, July 20–22, 2022

Meyer, N.; Werner, H. O.; Seuffert, J.; Dietrich, S.; Poppe, C.; Krauß, C.; Kärger, L.

2021, July 21. 5th International Conference on Hybrid Materials and Structures (2022), Leoben, Austria, July 20–22, 2022

A Benchmark for Fluid-Structure-Interaction in Hybrid Manufacturing: Simulation with preCICE in OpenFOAM

Dietrich, S.; Seuffert, J.; Werner, H.; Meyer, N.; Poppe, C.; Krauß, C.; Kärger, L.

2022, June 9. 8th European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2022), Oslo, Norway, June 5–9, 2022

Dietrich, S.; Seuffert, J.; Werner, H.; Meyer, N.; Poppe, C.; Krauß, C.; Kärger, L.

2022, June 9. 8th European Congress on Computational Methods in Applied Sciences and Engineering (ECCOMAS 2022), Oslo, Norway, June 5–9, 2022

Mold-filling Simulation of Resin Transfer Molding with Fluid-Structure Interaction. PhD dissertation

Seuffert, J.

2022, April 4. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000144393

Seuffert, J.

2022, April 4. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000144393

Hybrid material additive manufacturing: interlocking interfaces for fused filament fabrication on laser powder bed fusion substrates

Englert, L.; Heuer, A.; Engelskirchen, M. K.; Frölich, F.; Dietrich, S.; Liebig, W. V.; Kärger, L.; Schulze, V.

2022. Virtual and Physical Prototyping, 17 (3), 508–527. doi:10.1080/17452759.2022.2048228

Englert, L.; Heuer, A.; Engelskirchen, M. K.; Frölich, F.; Dietrich, S.; Liebig, W. V.; Kärger, L.; Schulze, V.

2022. Virtual and Physical Prototyping, 17 (3), 508–527. doi:10.1080/17452759.2022.2048228

Experimental and numerical analysis of mold filling in rotational molding

Nieschlag, J.; Seuffert, J.; Strack, D.; Friedmann, M.; Kärger, L.; Henning, F.; Fleischer, J.

2021. Journal of Composites Science, 5 (11), 289. doi:10.3390/jcs5110289

Nieschlag, J.; Seuffert, J.; Strack, D.; Friedmann, M.; Kärger, L.; Henning, F.; Fleischer, J.

2021. Journal of Composites Science, 5 (11), 289. doi:10.3390/jcs5110289

Micro-Scale Permeability Characterization of Carbon Fiber Composites Using Micrograph Volume Elements

Seuffert, J.; Bittrich, L.; Cardoso de Oliveira, L.; Spickenheuer, A.; Kärger, L.

2021. Frontiers in Materials, 8, Art. Nr.: 745084. doi:10.3389/fmats.2021.745084

Seuffert, J.; Bittrich, L.; Cardoso de Oliveira, L.; Spickenheuer, A.; Kärger, L.

2021. Frontiers in Materials, 8, Art. Nr.: 745084. doi:10.3389/fmats.2021.745084

Experimental and numerical investigations of pressure-controlled resin transfer molding (PC-RTM)

Seuffert, J.; Rosenberg, P.; Kärger, L.; Henning, F.; Kothmann, M. H.; Deinzer, G.

2020. Advanced manufacturing: polymer & composites science, 6 (3), 154–163. doi:10.1080/20550340.2020.1805689

Seuffert, J.; Rosenberg, P.; Kärger, L.; Henning, F.; Kothmann, M. H.; Deinzer, G.

2020. Advanced manufacturing: polymer & composites science, 6 (3), 154–163. doi:10.1080/20550340.2020.1805689

Numerical prediction of curing and process-induced distortion of composite structures. PhD dissertation

Bernath, A.

2021. KIT Scientific Publishing. doi:10.5445/KSP/1000125453

Bernath, A.

2021. KIT Scientific Publishing. doi:10.5445/KSP/1000125453

Investigations on intrinsically manufactured FRP/metal composites - from embedded inserts to load-bearing hybrid structures

Bernath, A.; Seuffert, J.; Muth, M.; Roth, S.; Fleischer, J.; Weidenmann, K. A.; Henning, F.

2020, April 29. 4th International Conference Hybrid - Materials and Structures (2020), Online, April 28–29, 2020

Bernath, A.; Seuffert, J.; Muth, M.; Roth, S.; Fleischer, J.; Weidenmann, K. A.; Henning, F.

2020, April 29. 4th International Conference Hybrid - Materials and Structures (2020), Online, April 28–29, 2020

Numerical prediction of curing and process-induced distortion of composite structures. PhD dissertation

Bernath, A.

2020, February 26. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000105945

Bernath, A.

2020, February 26. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000105945

Comparison of Finite Volume and Finite Element Methods for the Prediction of Process Induced Residual Stresses during Resin Transfer Molding

Bernath, A.; Henning, F.

2014. 27th International Workshop Research in Mechanics of Composites (2014), Bad Herrenalb, Germany, December 11–12, 2014

Bernath, A.; Henning, F.

2014. 27th International Workshop Research in Mechanics of Composites (2014), Bad Herrenalb, Germany, December 11–12, 2014

Holistic Development of High-Pressure RTM Composite Structures

Henning, F.; Bernath, A.; Galkin, S.; Kärger, L.; Magagnato, D.; Schirmaier, F.; Thoma, B.

2015. 31st International Conference of the Polymer Processing Society (PPS 2015), Jeju Island, Korea, June 7–11, 2015

Henning, F.; Bernath, A.; Galkin, S.; Kärger, L.; Magagnato, D.; Schirmaier, F.; Thoma, B.

2015. 31st International Conference of the Polymer Processing Society (PPS 2015), Jeju Island, Korea, June 7–11, 2015

Enhanced Viscosity Characterization for Fast Curing Epoxy Resins at Process Relevant Temperatures

Bernath, A.; Grulich, M.; Kärger, L.; Henning, F.

2018, May 31. 14th International Conference on Flow Processes in Composite Materials (2018), Luleå, Sweden, May 30–June 1, 2018

Bernath, A.; Grulich, M.; Kärger, L.; Henning, F.

2018, May 31. 14th International Conference on Flow Processes in Composite Materials (2018), Luleå, Sweden, May 30–June 1, 2018

Simulating Mold Filling in Compression Resin Transfer Molding (CRTM) Using a Three-Dimensional Finite-Volume Formulation

Seuffert, J.; Kärger, L.; Henning, F.

2018. Journal of composites science, 2 (2), Article: 23. doi:10.3390/jcs2020023

Seuffert, J.; Kärger, L.; Henning, F.

2018. Journal of composites science, 2 (2), Article: 23. doi:10.3390/jcs2020023

Experimental and numerical study of the spring-in of angled brackets manufactured using different resins and fiber textiles

Bernath, A.; Groh, F.; Exner, W.; Hühne, C.; Henning, F.

2019. Journal of composite materials, 53 (28-30), 4173–4188. doi:10.1177/0021998319855423

Bernath, A.; Groh, F.; Exner, W.; Hühne, C.; Henning, F.

2019. Journal of composite materials, 53 (28-30), 4173–4188. doi:10.1177/0021998319855423

Experimental and numerical study of the influence of integrated load transmission elements on filling behavior in resin transfer molding

Magagnato, D.; Seuffert, J.; Bernath, A.; Kärger, L.; Henning, F.

2018. Composite structures, 198, 135–143. doi:10.1016/j.compstruct.2018.05.021

Magagnato, D.; Seuffert, J.; Bernath, A.; Kärger, L.; Henning, F.

2018. Composite structures, 198, 135–143. doi:10.1016/j.compstruct.2018.05.021

Simulation of the influence of embedded inserts on the rtm filling behavior considering local fiber structure

Seuffert, J.; Kärger, L.; Henning, F.

2017. 21st Symposium on Composites, 2017; Bremen; Germany; 5 July 2017 through 7 July 2017. Ed.: A. S. Herrmann, 681–688, Trans Tech Publications. doi:10.4028/www.scientific.net/KEM.742.681

Seuffert, J.; Kärger, L.; Henning, F.

2017. 21st Symposium on Composites, 2017; Bremen; Germany; 5 July 2017 through 7 July 2017. Ed.: A. S. Herrmann, 681–688, Trans Tech Publications. doi:10.4028/www.scientific.net/KEM.742.681

Accurate Cure Modeling for Isothermal Processing of Fast Curing Epoxy Resins

Bernath, A.; Kärger, L.; Henning, F.

2016. Polymers, 8 (11), 390. doi:10.3390/polym8110390

Bernath, A.; Kärger, L.; Henning, F.

2016. Polymers, 8 (11), 390. doi:10.3390/polym8110390

An integrated development approach to combine design, manufacturing and validation of high-pressure RTM composite structures

Henning, F.; Bernath, A.; Chaudhari, R.; Kärger, L.; Magagnato, D.; Schirmaier, F.

2014. SAMPE Annual Tech Conference; 2.-5.06.2014, Seattle

Henning, F.; Bernath, A.; Chaudhari, R.; Kärger, L.; Magagnato, D.; Schirmaier, F.

2014. SAMPE Annual Tech Conference; 2.-5.06.2014, Seattle

Experimentelle und Numerische Untersuchung der Infiltration der RTM-Fertigung

Magagnato, D.; Frey, M.; Bernath, A.; Steibler, P.; Henning, F.

2013. 19. Symposium Verbundwerkstoffe und Werkstoffverbunde, Karlsruhe, 3.-5. Juli 2013

Magagnato, D.; Frey, M.; Bernath, A.; Steibler, P.; Henning, F.

2013. 19. Symposium Verbundwerkstoffe und Werkstoffverbunde, Karlsruhe, 3.-5. Juli 2013

_und_Kavit%c3%a4tsdruck_(rechts)_bei_der_Formf%c3%bcllung_eines_Fahrzeugunterbodens.png)