DFG MerVa

- Contact:

- Funding:

DFG

- Partner:

Leibniz-Institut für Polymerforschung Dresden e. V., Abteilung Verbundwerkstoffe

- Startdate:

01.02.2019

- Enddate:

31.01.2022

Methods and process development for the infiltration of highly loadable topology-optimized fiber-reinforced composites with a variable-axial fiber architecture

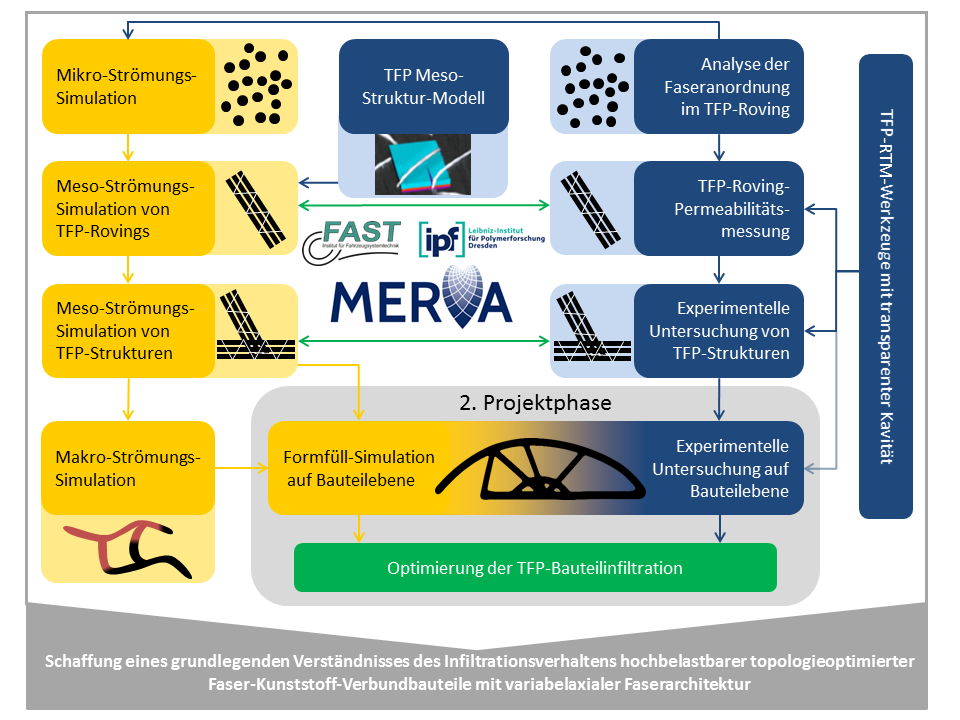

The research project MerVa (Method and process development for the infiltration of highly loadable topology-optimized fiber-plastic composite components with variable-axial fiber architecture) deals with the numerical and experimental investigation of the infiltration behavior of structural fiber-plastic composite (FPC) structures with variable-axial fiber architecture. This FRP design is considered to be particularly material-efficient and highly loadable, and thus suitable for many structural components. Topology optimization approaches are typically used for the design. The production of the structures is usually done with the Tailored Fiber Placement (TFP) process. However, up to now, a more widespread use of such an innovative fiber composite design has been hindered by unsolved questions regarding the infiltration of the textile preforms, e.g. by resin transfer molding. For example, the injection gates and the flow direction of the resin can so far only be determined and optimized manually and with a great experimental effort, because of the multi-scale infiltration behavior of the TFP preforms and the complex fiber architecture at the crossing points of TFP rovings.

In a joint project of the Leibniz Institute of Polymer Research Dresden e. V. (IPF) and the Karlsruhe Institute of Technology (KIT) these questions are investigated. The primary objective of the project is to create a fundamental understanding of the infiltration behavior of complex TFP preforms with variable fiber orientation. For this purpose, the microstructure of variable-axial TFP rovings will be analyzed experimentally. Furthermore, experimental investigations of the impregnation behavior on the meso and macro scale are performed. Based on the experimental results, flow simulation methods on the micro-, meso- and macro-scale are developed. Furthermore, the scalability of the occurring effects is investigated and corresponding homogenization approaches are evaluated. The aim of modeling at the macro level is to predict the filling behavior of the structural TFP components with sufficient accuracy and efficiency to enable virtual optimization and validation of infiltration processes in the future.