HyCEML - Hybrid CFRP / elastomer / metal laminates with elastomer layers for targeted adjustment of damping behavior

- Contact:

- Funding:

DFG - Deutsche Forschungsgemeinschaft

- Partner:

Institute for Applied Materials - Materials Science and Engineering - Hybrid and Lightweight Materials

- Startdate:

September 2016

- Enddate:

September 2022

DFG-priority programme 1897 calm, smooth, smart: HyCEML - Hybrid CFRP / elastomer / metal laminates with elastomer layers for targeted adjustment of damping behavior

Motivation

Lightweight design is used to increase efficiency in all kinds of vehicles. Although common lightweight materials offer a high specific stiffness at a low mass, monolithic materials rarely fulfill all requirements. A composite laminate made from layers of CFRP, elastomer and metal for example enables the specific adjustment of the damping capabilities of lightweight structures, which are usually prone to strong vibrations. This material is based on common fiber metal laminates:

CFK/Metall-Laminate:

- High energy absorption under impact loading

- Susceptible to corrosion

Elastomere Zwischenschicht:

- Adjustment of the damping behavior

- Compensation of thermal residual stresses

- Prevention of galvanic corrosion

- Replaces adhesive

Scientific goals

This project’s main objective is the scale bridging experimental and numerical analysis of the dynamics, such as damping and natural frequencies to name a few, of HyCEML. The two project partners FAST and IAM-WK pursue the following goals:

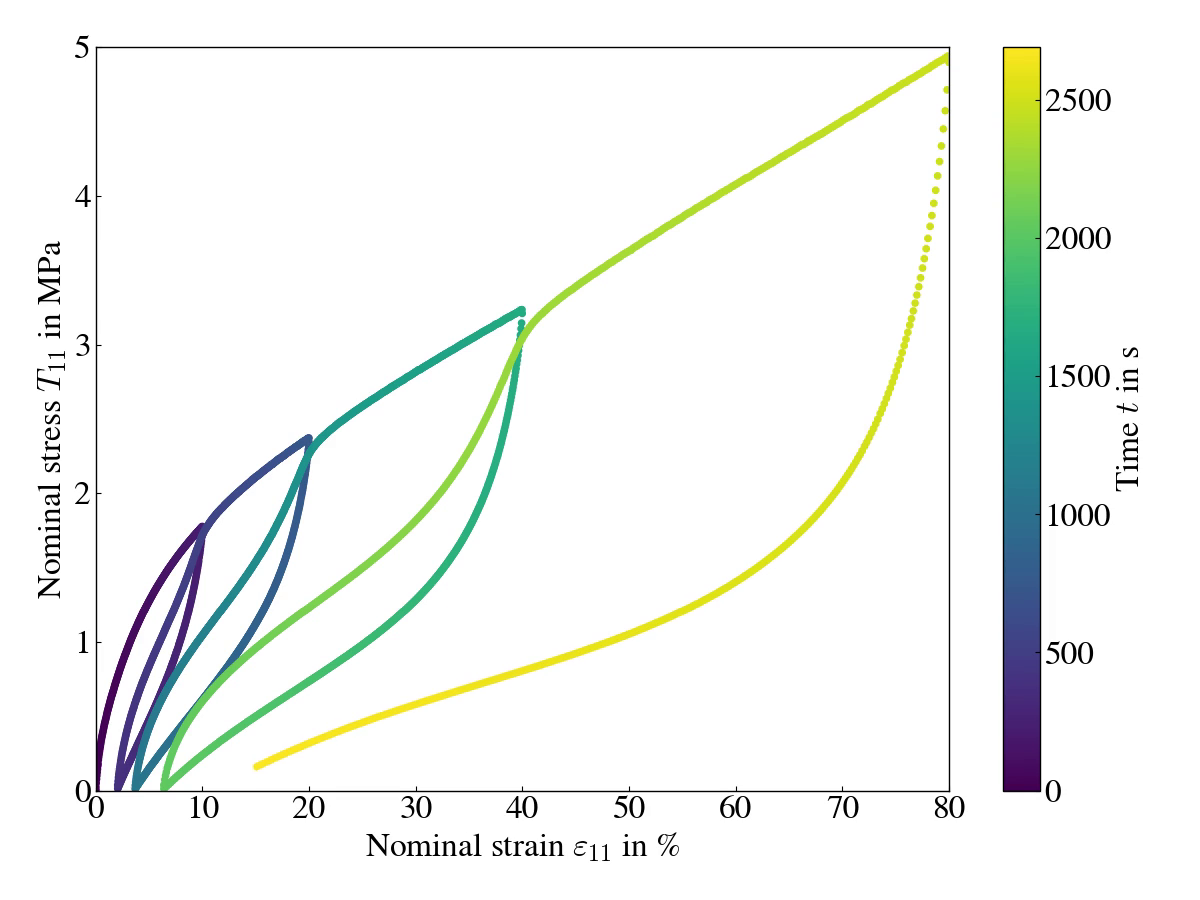

- Experimental characterization of the Mullins effect in the hybrid laminates and its constitutive modeling with suitable material models

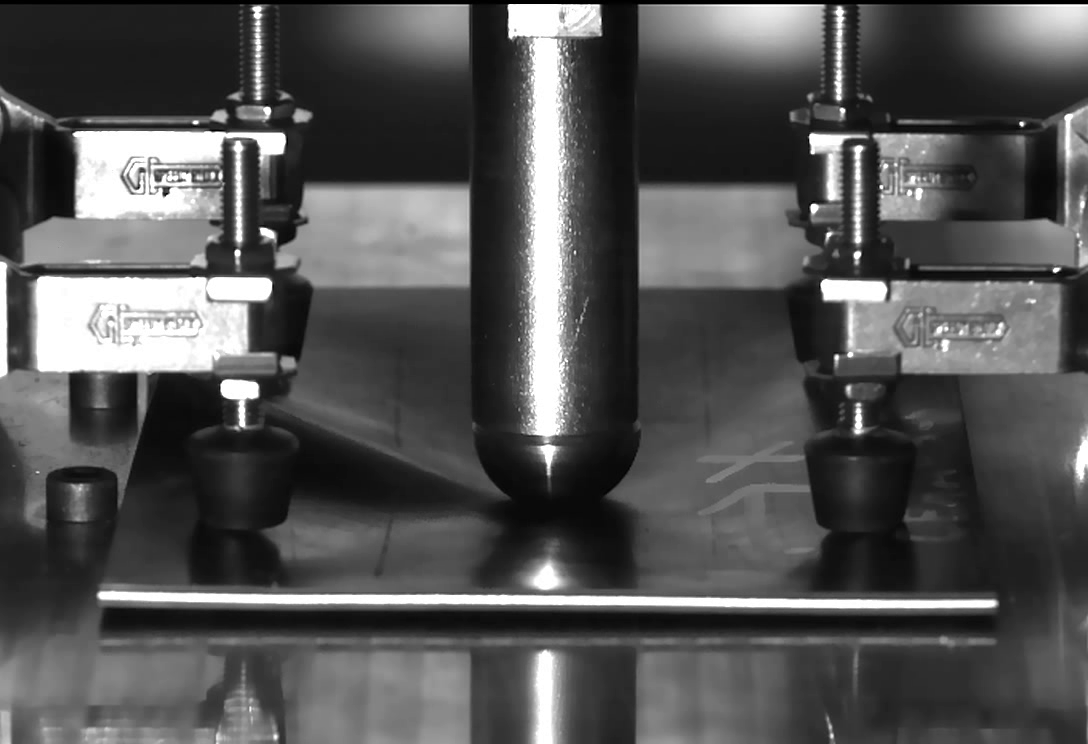

- Identification of damage mechanisms occurring under low-velocity impact in HyCEML

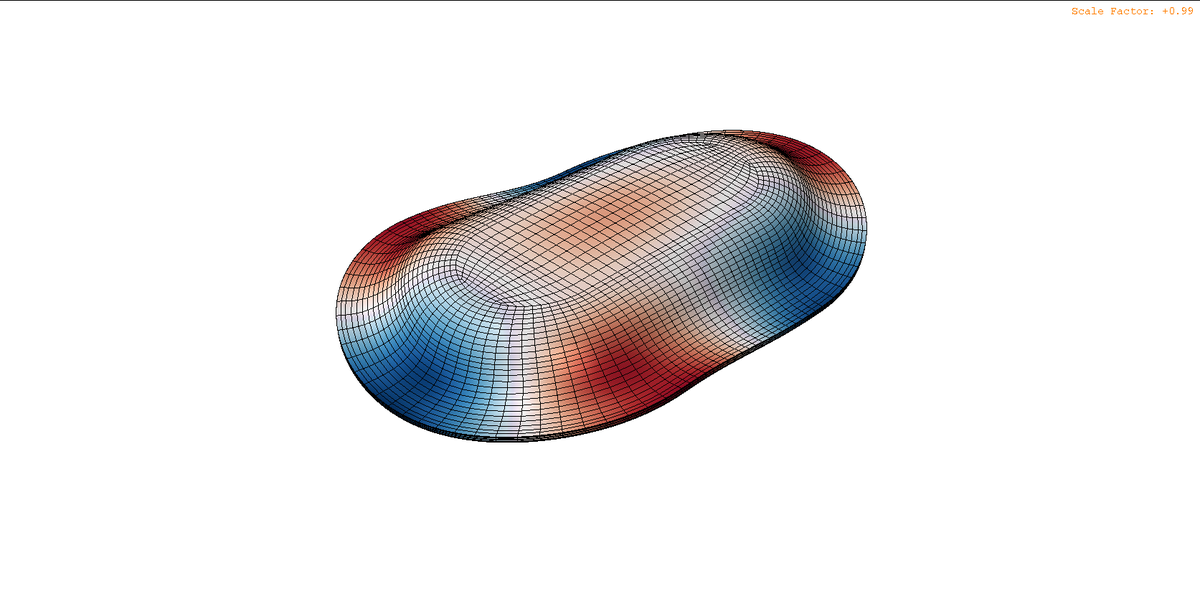

- Consideration of these damage mechanisms in fine-element models for the efficient analysis of damaged components

- Identification of different damage mechanisms’ influence on the dynamic behavior of HyCMEL

- Deduction of guidelines for the damage tolerant design of well damped laminates

Methods

- Intrinsic manufacturing process of laminates in press process

- Quasi-static characterization of constituents and hybrid laminates

- Dynamic-mechanical-analysis and modal analysis

- Closed-form analytical solutions for the rapid prediction of the vibrational behavior of hybrid laminates

- Complex material models depicting different kinds of damage mechanism within the laminate