DFG Hybrides Tiefziehen

- Contact:

- Funding:

DFG – Deutsche Forschungsgemeinschaft

- Partner:

Institut für Angewandte Materialien - Werkstoffkunde (IAM-WK)

Fraunhofer-Institut für Chemische Technologie (ICT) - Startdate:

05/2015

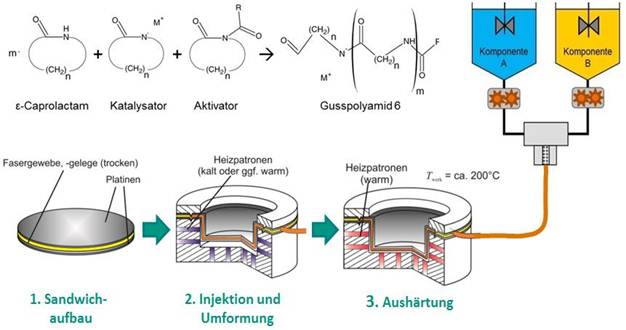

In situ hybridization during thermoforming - Thermoplastic fiber-metal laminate (FML) components based on reactively processed cast polyamide 6.

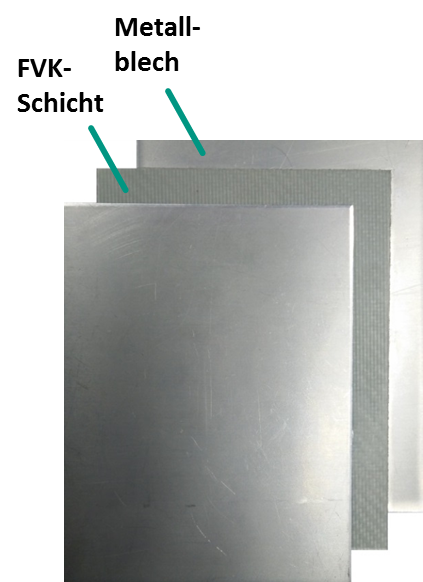

Fiber-metal laminates (FML) are hybrid materials consisting of several fiber-plastic composite (FRP) layers, each often only a few tenths of a millimeter thick, and metal sheets.

Fiber-metal laminates (FML) are hybrid materials consisting of several fiber-plastic composite (FRP) layers, each often only a few tenths of a millimeter thick, and metal sheets.

In addition to very good weight-specific mechanical strengths and stiffnesses, FMLs are characterized in particular by their excellent impact and fatigue properties.

However, complex multi-stage manufacturing processes with low forming ratios currently prevent large-scale series production of FMLs in mobile lightweight construction.

The aim of this research project is therefore to develop a process for the production of near-net-shape FML structural components by combining deep-drawing and thermoplastic resin transfer molding (T-RTM) processes.

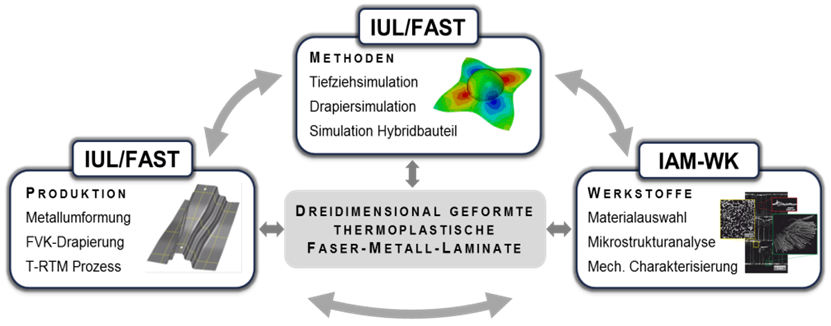

Corresponding research topics are the simulation of the forming and draping behavior of T-FML considering the interactions of fiber and metal layers, the intrinsic fabrication of near-net-shape 3D formed T-FML devices by in situ polymerization and hybridization during the forming process, and the investigation of the process-structure-property relationships and damage evolution of T-FML.