Optimization

For maximal lightweight potential and optimal manufacturability, part geometry, material and process must match in mutual regard and thus, part and process conceptualisation impact most on final part performance. Besides rigorous analysis of process dynamics, simulations enable an automated search of optima during part design.

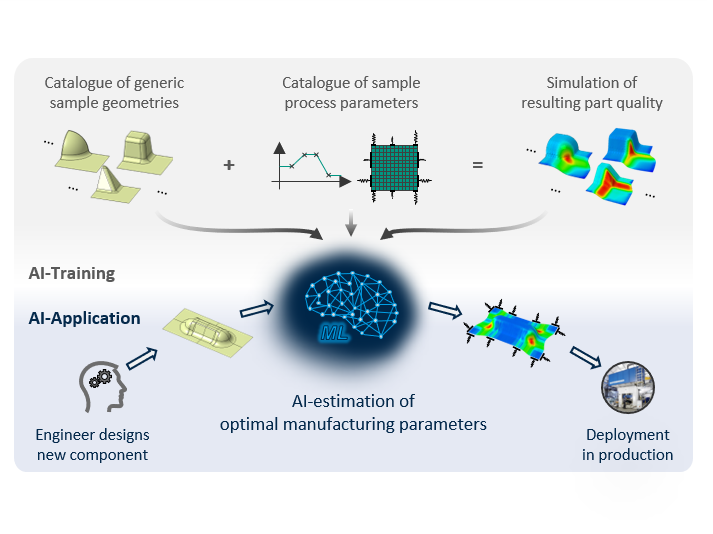

We couple our elaborate and detailed simulation models with optimisation algorithms. Apart from definition of suitable optimisation objectives we also focus on computational efficiency: For instance, AI-Models can guide the optimiser’s search and concentrate costly simulations on the most promising variants. This reduces the computational effort by up to 70%.

Research focus

- Laminate optimisation

- Topology optimisation

- Optimisation of local reinforcements (patches)

- AI-assisted manufacturing process optimisation

- Development of efficient process models

Research projects |

ContactM.Sc. Tobias Würth |

Selected publications in the research field

Böhnke, B. H.; Eismont, A.; Zimmerling, C.; Kärger, L.; Böhm, K.

2024. Procedia CIRP, 130, 145–153. doi:10.1016/j.procir.2024.10.069

Frölich, F.; Hof, L.; Zimmerling, C.; Wittemann, F.; Kärger, L.

2024. The International Journal of Advanced Manufacturing Technology. doi:10.1007/s00170-024-14913-w

Würth, T.; Freymuth, N.; Zimmerling, C.; Neumann, G.; Kärger, L.

2024. Computer Methods in Applied Mechanics and Engineering, 429, Artkl.Nr.: 117102. doi:10.1016/j.cma.2024.117102

Würth, T.; Prietze, A.; Zimmerling, C.; Krauß, C.; Kärger, L.

2023. NAFEMS-Magazin, 68 (4), 39–45

Zimmerling, C.

2024, March 4. Society for the Advancement of Material and Process Engineering Europe Summit (SAMPE 2024), Paris, France, March 4, 2024

Zimmerling, C.

2023, April 20. 26th International ESAFORM Conference on Material Forming (ESAFORM 2023), Krakow, Poland, April 19–21, 2023

Zimmerling, C.

2023, March 22. 27. Nationales SAMPE Symposium Deutschland (2023), Munich, Germany, March 21–22, 2023

Zimmerling, C.

2023, September 26. ITA Reinforced! Innovation Day: “Automation” and “Composite Testing and Sensor Integration” (2023), Aachen, Germany, September 26, 2023

Zimmerling, C.; Kärger, L.

2023. Material Forming 26th International ESAFORM Conference on Material Forming (ESAFORM 2023) Krakau, Polen, 19.04.2023–21.04.2023, 1155–1166, Materials Research Forum LLC. doi:10.21741/9781644902479-126

Würth, T.; Krauß, C.; Zimmerling, C.; Kärger, L.

2023. Materials & Design, 231, Art.-Nr.: 112034. doi:10.1016/j.matdes.2023.112034

Zimmerling, C.

2023, January 18. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000154623

Zimmerling, C.; Fengler, B.; Kärger, L.

2022. Key Engineering Materials, 926, 2247–2257. doi:10.4028/p-1o0007

Zimmerling, C.; Kärger, L.; Carosella, S.; Middendorf, P.; Henning, F.

2019, May 20. 6. Technologietag Hybrider Leichtbau (2019), Leinfelden-Echterdingen, Germany, May 20–21, 2019

Zimmerling, C.; Poppe, C.; Stein, O.; Kärger, L.

2022. Materials and Design, 214, Art.-Nr.: 110423. doi:10.1016/j.matdes.2022.110423

Zimmerling, C.; Schindler, P.; Seuffert, J.; Kärger, L.

2021. ESAFORM 2021 - 24th International Conference on Material Forming, ULiège Library. doi:10.25518/esaform21.3882

Zimmerling, C.; Fengler, B.; Wen, H.; Fan, Z.; Kärger, L.

2020, September 1. 23rd / 6th Joint Event: International Conference on Composite Structures - International Conference on Mechanics of Composites (ICCS / MECHCOMP 2020), Porto, Portugal, September 1–4, 2020

Zimmerling, C.; Poppe, C.; Kärger, L.

2019. Lightweight Design worldwide, 12 (6), 12–19. doi:10.1007/s41777-019-0064-x

Zimmerling, C.; Poppe, C.; Kärger, L.

2020. Procedia manufacturing, 47, 847–854. doi:10.1016/j.promfg.2020.04.263

Fengler, B.

2021. KIT Scientific Publishing. doi:10.5445/KSP/1000104717

Fengler, B.; Schäferling, M.; Schäfer, B.; Bretz, L.; Lanza, G.; Häfner, B.; Hrymak, A.; Kärger, L.

2019. Hospital physician, 213, 47–57. doi:10.1016/j.compstruct.2019.01.063

Zimmerling, C.

2019. Carbon-Composites-Magazin, (1), 19–20

Zimmerling, C.; Pfrommer, J.; Liu, J.; Beyerer, J.; Henning, F.; Kärger, L.

2018. 18th European Conference on Composite Materials (ECCM 2018), Athen, GR, June 24-28, 2018

Zimmerling, C.; Trippe, D.; Fengler, B.; Kärger, L.

2019. Proceedings of the 22nd International ESAFORM Conference on Material Forming ; Vitoria-Gasteiz, Spain, 8–10 May 2019. Ed.: L. Galdos, Art.-Nr.: 020007, American Institute of Physics (AIP). doi:10.1063/1.5112512

Zimmerling, C.; Dörr, D.; Henning, F.; Kärger, L.

2019. Composites / A, 124, Art. Nr.: 105459. doi:10.1016/j.compositesa.2019.05.027

Fengler, B.; Hrymak, A.; Kärger, L.

2019. Hospital physician, 221, Art. Nr.: 110861. doi:10.1016/j.compstruct.2019.04.033

Fengler, B.

2019. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000089502

Zimmerling, C.; Dörr, D.; Henning, F.; Kärger, L.

2018. Proceedings of the 21st International ESAFORM Conference on Material Forming : ESAFORM 2018 : Palermo, Italy, 23-25 April 2018. Ed.: L. Fratini, Art.Nr. 020042, American Institute of Physics (AIP). doi:10.1063/1.5034843

Kärger, L.; Galkin, S.; Zimmerling, C.; Dörr, D.; Linden, J.; Oeckerath, A.; Wolf, K.

2018. Composite structures, 192, 143–152. doi:10.1016/j.compstruct.2018.02.041