Our Profile

Lightweight Engineering (LB)

Lightweight Engineering is positioned as a cross-sectional topic at the Institute of Vehicle System Technology (FAST) at the Karlsruhe Institute of Technology. Research activities focus on technologies for reducing the weight of vehicles, with a focus on fiber composites in the context of monolithic as well as hybrid structures. With regard to application-oriented and market-relevant research, the LB pursues two objectives:

Fig. 1: Holistic research and development of technologies to ensure maximum affordable lightweighting with high-performance fiber composites for large-scale production.

Fig. 2: Optimal utilization of the lightweight potential of semi-structural long fiber composites with maximum, best possible functional integration.

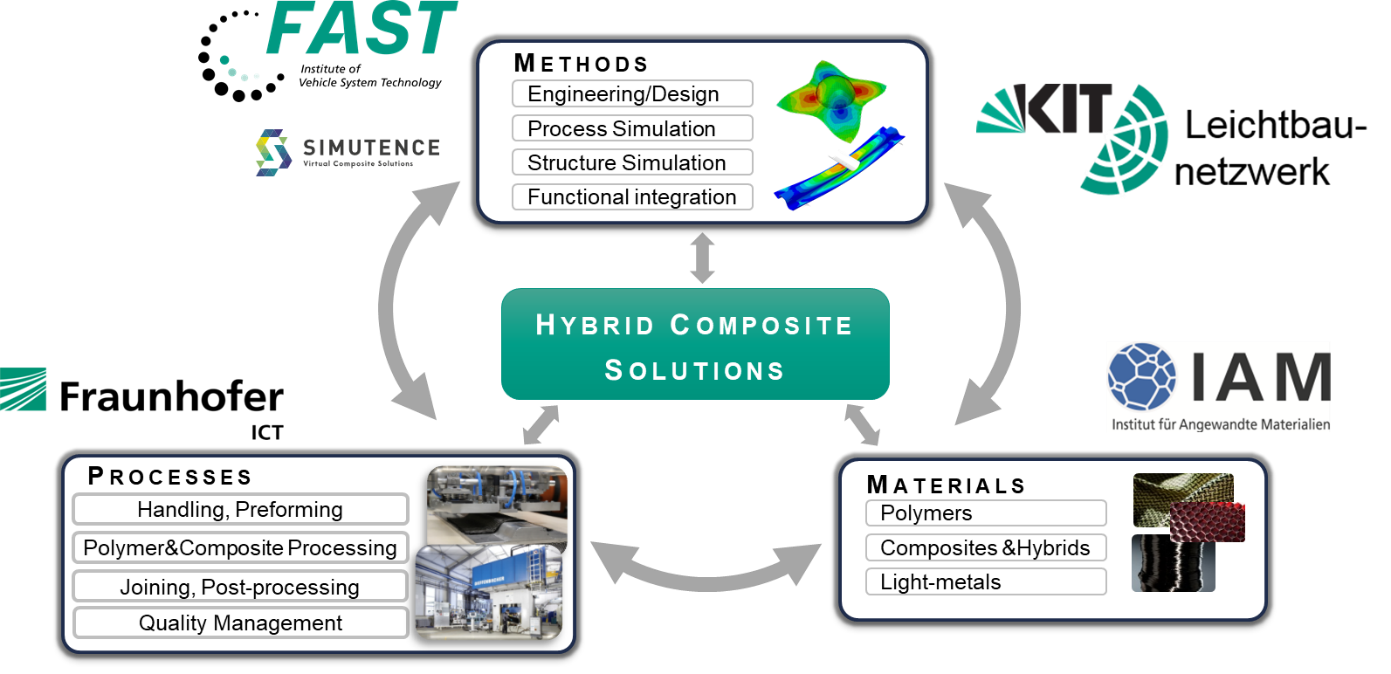

For the development of large-series, lightweight and high-performance fiber composites as well as hybrid components, it is essential to holisitcally apply competencies from the fields of methods, materials and production. This is the basis for the Methods-Materials-Production (MMP) approach. Against this background, FAST-LB pursues a holistic engineering approach to lightweight design in close cooperation with the Department of Polymer Engineering (PE) of the Fraunhofer Institute for Chemical Technology (ICT), the Division for Hybrid Materials and Lightweight Design of the Institute for Applied Materials (KIT-IAM-WK) and further partners of the KIT Lightweight Design Network.

Fig. 3: To develop high-performance lightweight solutions which can be manufactured on an industrial scale, it is essential to concentrate and connect competences in the fields of Methods, Materials and Processes (MMP approach).

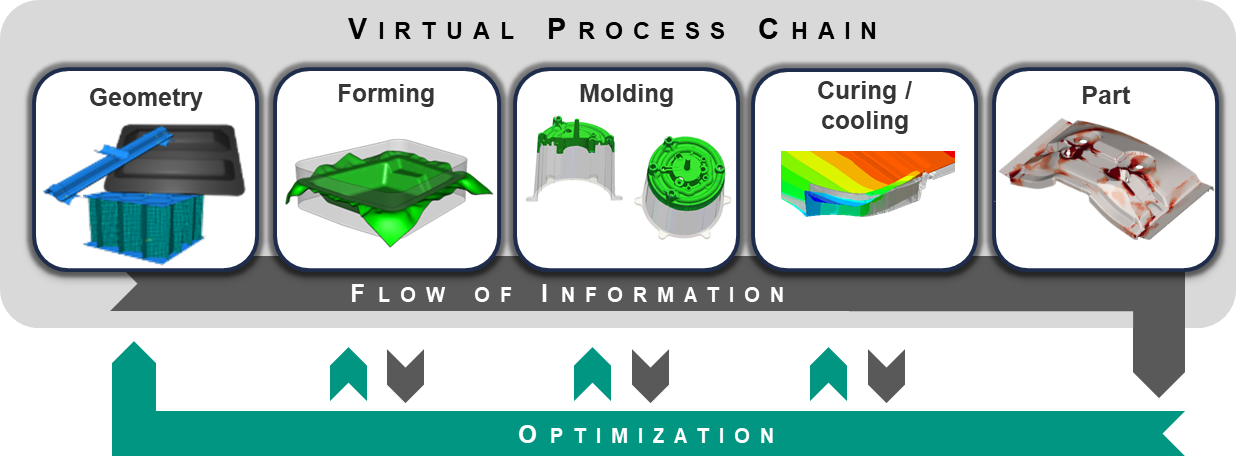

In the area of Method development (M), simulation methods and continuous virtual process chains (CAE chains) are developed at FAST-LB for the virtual description of the manufacturing processes of long fiber and continuous fiber composite components. The CAE-chains allow to consider the complex interactions between component design, manufacturing, material properties and the resulting component behavior already in the early stages of product development. For this purpose, FAST-LB develops material models and simulation methods for the different manufacturing process steps as well as for structural simulation. The manufacturing process steps include forming, molding (RTM, WCM, compression and injection molding, etc.), curing, cooling and distortion. Details on our research work are described under Research.

Fig. 4: Continuous virtual process chain for fiber-reinforced plastic components.

In the field of process and material development, FAST-LB cooperates closely with the Fraunhofer ICT and the KIT-IAM-WK and conducts research on high-volume process technologies in the fields of SMC, LFT, injection molding, RTM, T-RTM, wet compression molding, tape laying, and fiber spraying. In particular, process-integrated material preparation and modification as well as automation and quality assurance of intrinsically and extrinsically hybridized fiber composite components are researched.

Your Contacts:

| Prof. Dr.-Ing. Luise Kärger | Prof. Dr.-Ing. Frank Henning |

|

Head of the Institute Division, Professor of Digitalization in Lightweight Construction |

Professor of Lightweight Technology, Member of the Vehicle Systems Technology Directorate |

| Tel.: +49 721 608-45386 | Tel.: +49 721 608-45384 |

| luise.kaerger∂kit.edu | frank.henning∂kit.edu |

| Dr.-Ing. Florian Wittemann | M.Sc. Constantin Krauß |

| Group leader mold filling simulation | Group leader forming and structural simulation |

| Tel.: +49 721 608-45379 | Tel.: +49 721 608-45896 |

| florian.wittemann∂kit.edu | constantin.krauss∂kit.edu |