Forming

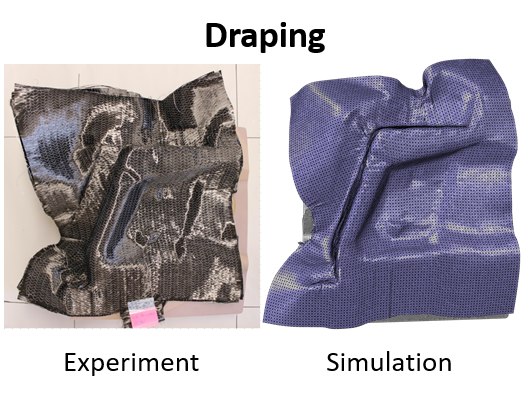

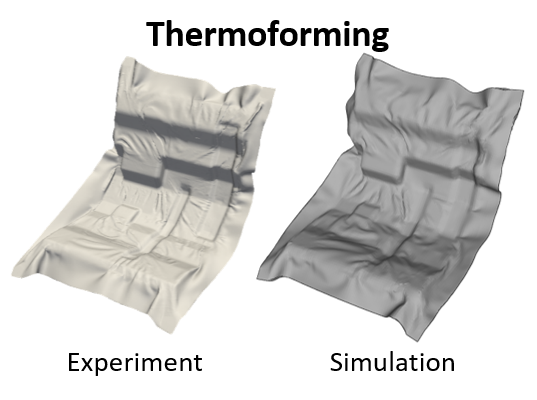

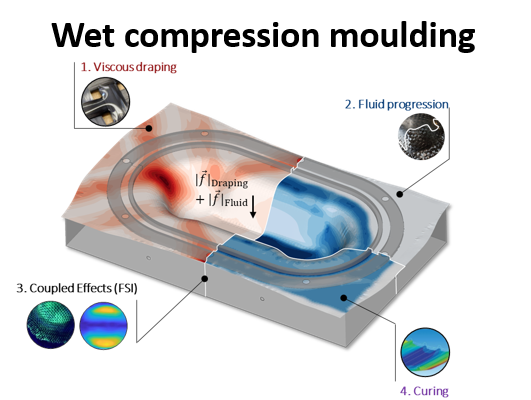

In the field of forming simulation, methods for the prediction of the forming behaviour of textile and pre-impregnated semi-finished products are developed. Our institute focuses on dry woven or non-crimp fabrics, unidirectionally reinforced thermoplastic tapes (UD-Tapes) as well as on the combination of textile draping and infiltration in one process step, which is especially relevant for wet compression moulding. For the macroscopic description of the semi-finished products during processes, we develop methods for forming simulation by implementing suitable finite user-elements, material models and contact models, based on the commercial FE solver Abaqus. In addition, state of the art methods for the characterization of semi-finished products are conducted in cooperation with the KIT-IAM-WK and Fraunhofer ICT, and customized characterization methods are developed for new material systems.

Research focus

- Efficient macroscopic simulation models for component forming

- Prediction of forming effects and defects (e.g. fiber orientation, wrinkling, gapping)

- Development of suitable material models considering the anisotropic membrane and bending behavior of semi-finished products

- Thermomechanical and rate-dependent modelling of UD-tapes considering crystallization kinetics (cooling)

- Strong fluid-structure interaction for the infiltration during wet compression processes

- Efficient consideration of mesoscopic effects (e.g. fibre bending) on a macroscopic scale

- Development of three dimensional modelling approaches to consider compaction during forming simulations

Research projects |

ContactM.Sc. Johannes Mitsch

M.Sc. Jan Paul Wank

|