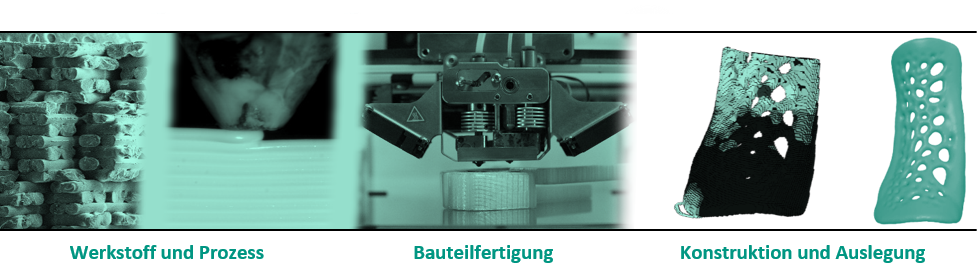

Design of additively manufactured polymer structures using medical applications as an example

Lecture with project part

Motivation and background

In this course, students learn about the individualized, additive manufacturing of polymer components and apply them independently in a semester-long development project. The course first provides an overview of established AM process technologies and uses the example of extrusion processes to work out the interaction between material, process settings and design. Special requirements of medical technology for component development and material selection are presented in separate lectures. This is followed by an application-oriented introduction to the practical component design of printed polymer structures using the finite element method (FEM). FE-based topology optimization is presented as a particularly suitable idea generator for efficient design solutions. The CAE design methods are specifically deepened in practice in exercises. Equipped with knowledge of processes, materials and methods, students finally solve an individual development project from the field of orthotics in small groups.

Content:

-

Overview of additive manufacturing processes(3D printing, additive manufacturing)

-

Interaction process-material-component

-

Polymers in additive manufacturing:

Material science fundamentals, material and component testing. -

Special aspects of additive manufacturing in medical technology (external guest contributions)

-

Computer-aided component design and optimization (lectures and exercises)

-

Semester project: Design, manufacture and testing of a component from the field of "medical technology

Lecturer: Prof. Dr.-Ing. Luise Kärger (FAST-LB)

Registration: This semester, no additional registration via the website is necessary. The course is open and accessible without limit.

|

Language: German

|

Period: Summer Semester

Lecture & Lecture Hall Exercise:

Tuesdays 2:00 – 3:30 p.m. Building 70.04, East Campus, Room 112

Consultations:

At 3:45 – 5:15 p.m. on the following days:

Building 70.04, Campus Ost, Room 125

|

Outcome Assessment: Testate (ungraded) Final project + oral exam (graded) |

Effort:

3 SWS and 4 LP.