Fiber composite processes

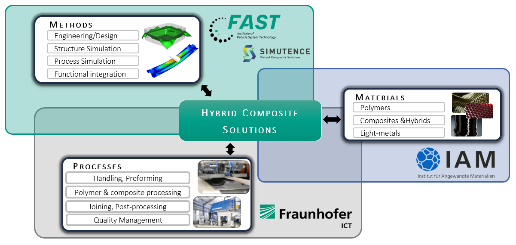

For the development of large-scale, lightweight and high-performance fibre composites and hybrid components, it is vital to combine competencies from the disciplines of methods, materials and production and use them holistically.

Methods development at the KIT Institute "FAST Lightweight Engineering" involves the development of simulation methods and integrated virtual process chains (CAE chains) for the virtual description of the manufacturing process chains of fibre composite components.

The CAE chains allow to consider and predict complex interactions between component design, manufacturing, material properties and the resulting part behaviour already in the early phases of product development.

Our mission

-

Method development for the efficient virtual validation of manufacturing processes

-

Consideration of manufacturing effects within a continuous process chain

-

Early support in process development

-

Optimisation of fibre-reinforced structural components and process sequences

Our expertise

A comprehensive list of ongoing and completed projects can be found here. |

Your contact persons

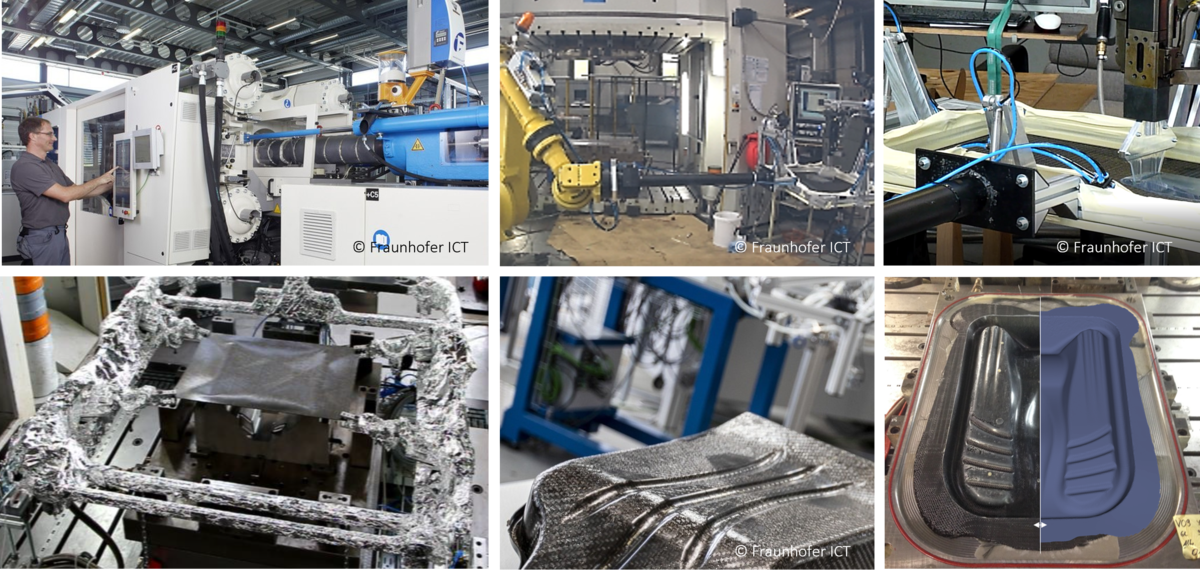

Processes(Fraunhofer ICT)

Methods

Materials (Institute for Material Scince) |