TraCLight - Transatlantic Cluster for Lightweighting

- Contact:

- Funding:

Bundesministerium für Bildung und Forschung (BMBF)

- Startdate:

23.07.2019

- Enddate:

01.07.2022

TraCLight - Transatlantic Cluster for Lightweighting

Cost and resource efficient manufacturing of FRP-metal hybrid structures in Wet Compression Moulding

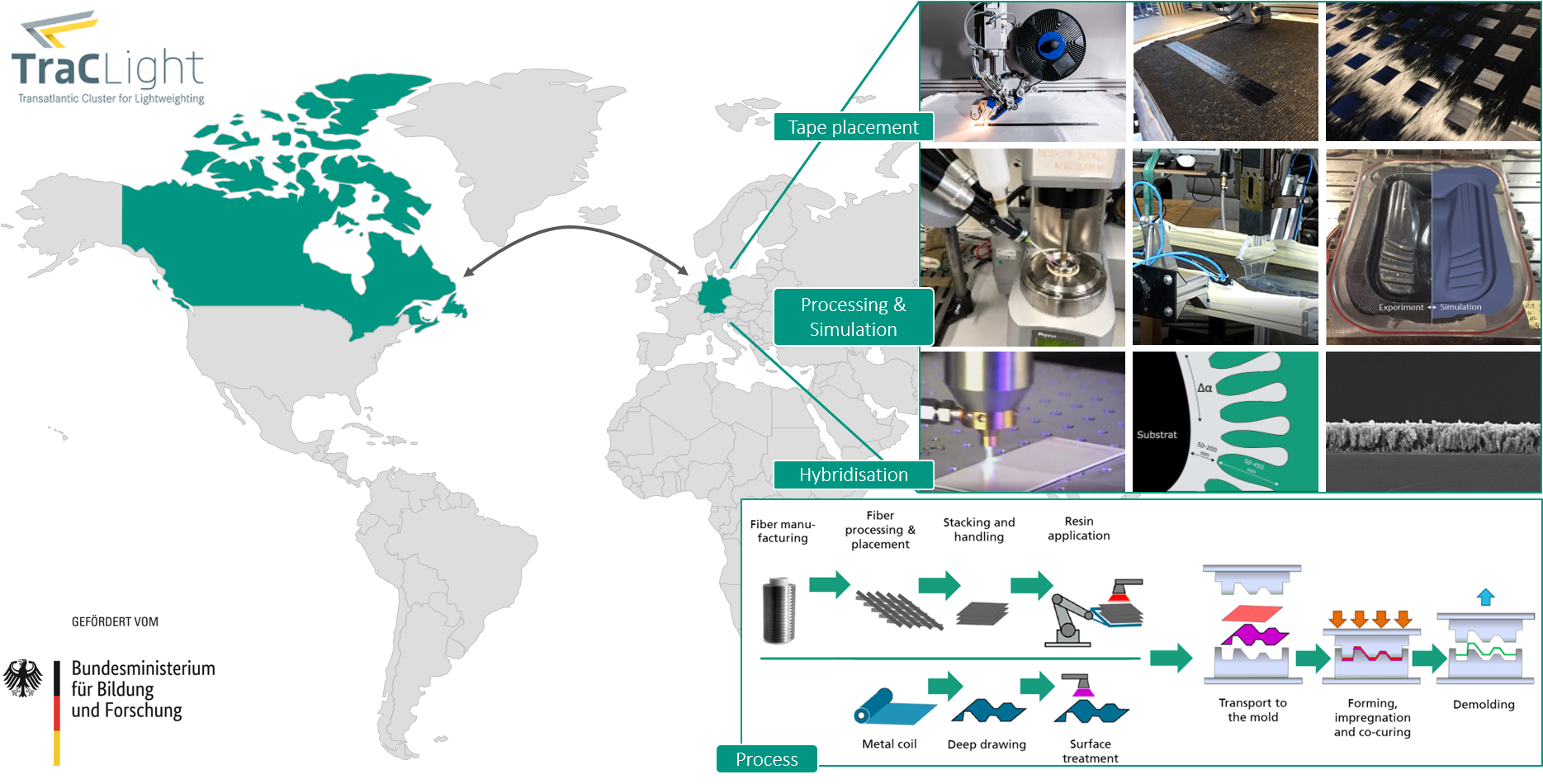

The overall strategic goal of the project is to strengthen the transatlantic cooperation between German and North American companies in the field of lightweight construction. This includes the pooling of competencies, the joint advancement of current research topics and the development of new and effective cooperation mechanisms. The overall scientific objective of the project is the development of advanced technologies for hybrid Wet Compression molding, which enables an economical production of complex, FRP-metal hybrid structures in large quantities for automotive applications.

Figure 1: Process and project work on the German side

The German partners are developing fabric structures made of basalt and carbon fibres, which are to be infiltrated and hybridised directly using wet compression moulding. In addition to process development and the development of numerical models, the focus of research is on the functionalisation of surfaces and direct hybridisation. The project results are to be concluded in a complex demonstrator.

The process development and material characterisation is carried out in cooperation between the Fraunhofer ICT and the KIT. Based on this, suitable simulation methods for process design will be developed at KIT-FAST. A physical understanding of the process will be developed, which will further enable technologies, materials and methods to allow even more sustainable and efficient lightweight construction solutions.

Partner:

Deutsche Partner:

Kanadische Partner: