MWK Forschungsbrücke Karlsruhe-Stuttgart

- Contact:

- Funding:

Our gratitude belongs to the Ministry of Science, Research and Art (MWK) in Baden-Württemberg for funding this innovative project

- Partner:

Universität Stuttgart – Institut für Flugzeugbau (IFB), Karlsruher Institut für Technologie - Institut für Fahrzeugsystemtechnik (FAST)

- Startdate:

01.10.2016

- Enddate:

30.06.2020

Forschungsbrücke Karlsruhe - Stuttgart

„Time and cost-efficient product development for high-performance lightweight fiber composite design using wet-pressing technology “

The “Forschungsbrücke” project relies on the experience of the long-standing supraregional cooperation of KIT and the University of Stuttgart to develop a sustainable understanding of technology in the field of wet compression molding. In essence, the following objectives were achieved:

- Investigation of production processes suited for large volume production of high-performance fiber composite structures using wet pressing technology

- Development of a physically based process understanding, numerical method development and holistic process and product optimisation as well as a methodology for current and cost-efficient fatigue characterisation

- Competence focusing and strategic strengthening of the cooperation between the lightweight design institutes KIT-FAST and IFB Stuttgart

- Establishment of evaluation criteria and process limits for the wet pressing process at component level

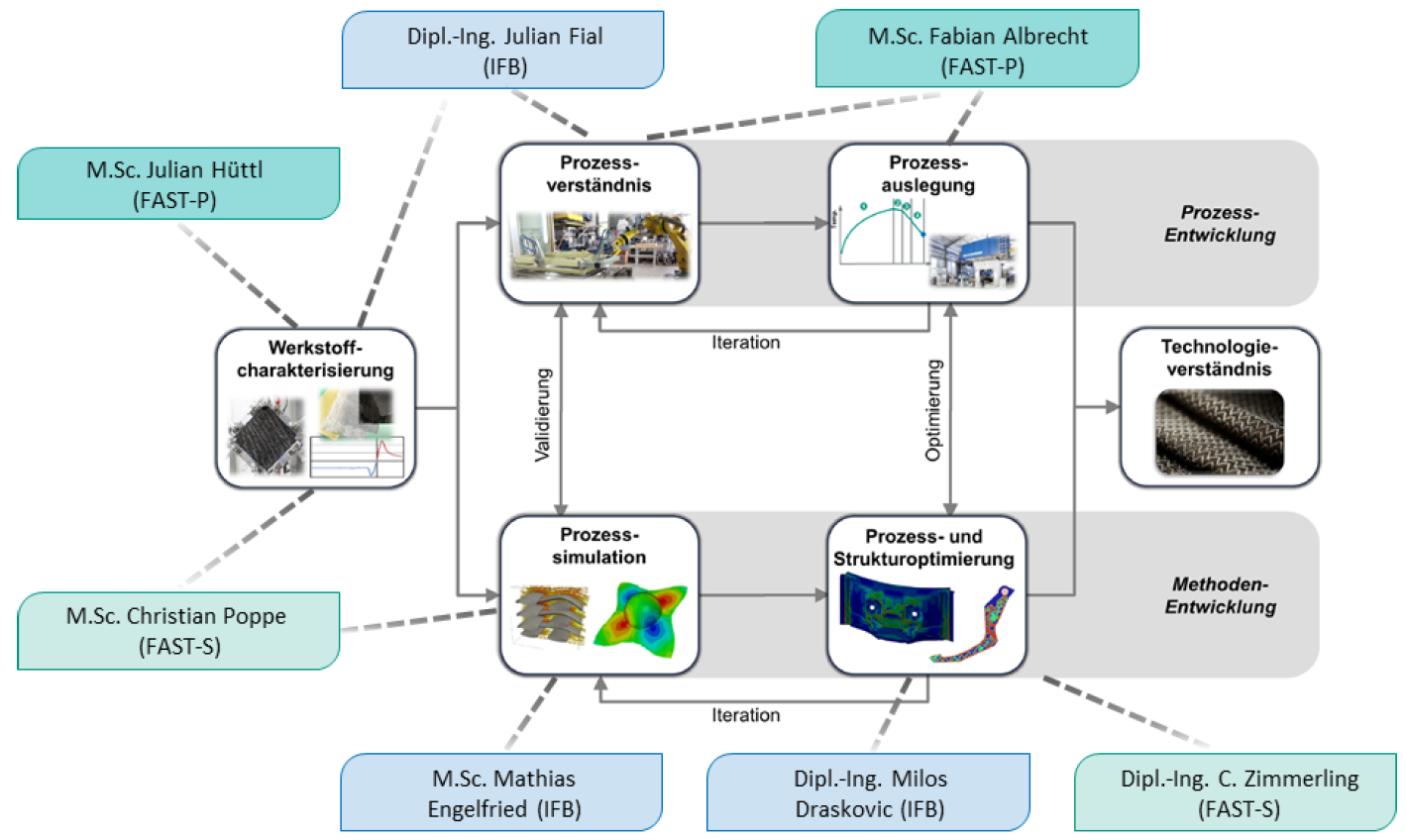

Under the coordination of KIT-FAST, the cooperation structure shown in Figure 1 was developed and successfully implemented within the project:

Fig. 1: Project content and methodology

The "Forschungsbrücke" project has significantly strengthened and improved the technical cooperation between KIT and the University of Stuttgart in the field of lightweight design. The scientific aim of the collaborative project was the development and maturation of WCM process for resource-efficient lightweight construction in the future. Substantial new insights, new process strategies and simulation methods were developed for this future-oriented fiber composite technology. This has resulted in numerous national and international publications (see references):

- 3 journal articles (peer-reviewed)

- 2 articles in related magazines

- 21 conference proceedings (peer-reviewed)

- 4 presentations at annual technology meetings

- 7 additional publications

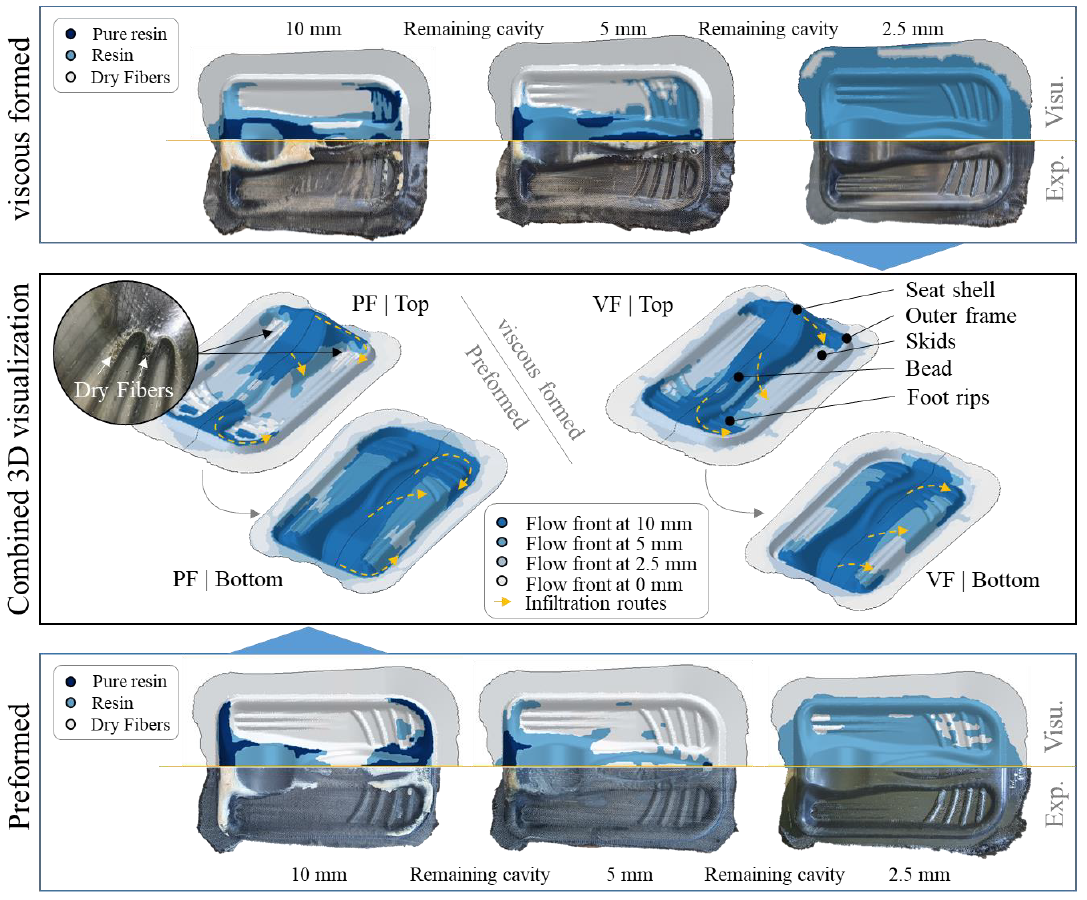

Due to the research results achieved in the project, KIT-FAST and IFB Stuttgart are among the internationally leading research institutes in the field of wet compression molding. This concerns both the process technology and the simulation methods for prediction; analysis and optimization of the complex multi-physical process. For example, it could be shown that the infiltration behavior of complex components differs significantly, depending on whether a preforming step is applied beforehand (see Figure 2).

Figure 2: Comparison of process variants with and without preforming applied to a complex demonstrator [Alb20]

Figure 2: Comparison of process variants with and without preforming applied to a complex demonstrator [Alb20]

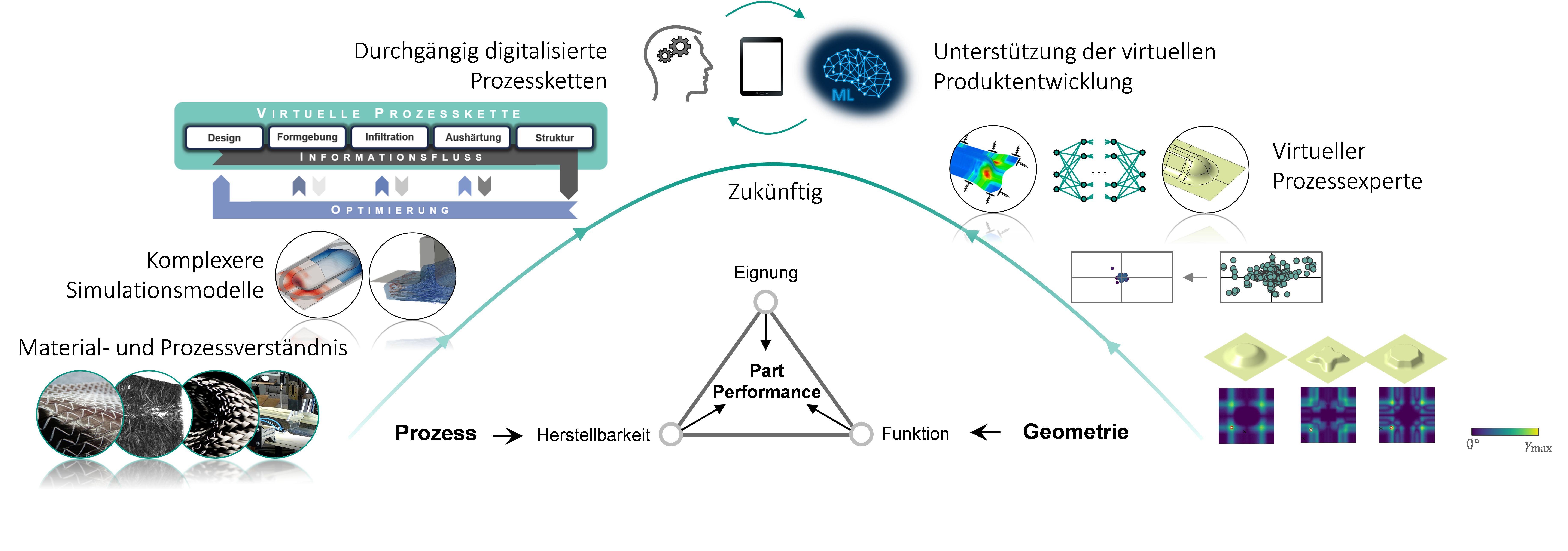

Moreover, the project has also addressed future developments in the field of virtual design of CFRPs by combining complex simulation methods and methods for artificial intelligence (Figure 3).

Figure 3: Future AI-support of continuously digitalized product development [Zim19e]

With the achieved results and the consolidated cooperation, the “Forschungsbrücke” project is an asset for the institutes FAST and IFB as well as for the technology knowledge in Baden-Württemberg, both in technical and structural terms.

If you want to learn more, register for our final colloquium!

References

FAST-P

[Alb18]: Nasspresstechnologie Prozess- und Produktentwicklung für den Hochleistungsfaserverbundleichtbau, Vortrag, 16. Kunststoffkolloquium, Hechingen, 2018.

[Alb19] Albrecht F, Zimmerling C, Poppe C, Kärger L, Henning F: Development of a modular draping test bench for analysis of infiltrated woven fabrics in wet compression molding, Conference Proceeding DGM-Konferenz, 22. Symposium „Verbundwerkstoffe und Werkstoffverbunde, 2019.

[Alb20]: Albrecht F, Poppe C, Fial J, Henning F, Middendorf, P: Effect of process routing (direct vs. preformed) on part infiltration during Wet Compression Molding (WCM) of a complex demonstrator, Conference Proceedings SAMPE 2020, 2020.

[Hüt17] Hüttl J., Albrecht F., Poppe C., Lorenz F., Thoma B., Kärger L., Middendorf P., Henning F.; Investigations on friction behaviour and forming simulation of plain woven fabrics for wet compression moulding, Conference Proceedings SAMPE 2017.

FAST-S

[Esa20] European Scientific Association for Material Forming (ESAFORM): Best communication award, Web-Information, https://www.esaform.utwente.nl/index.php/esaform-prizes/best-communication-award , zuletzt aufgerufen am 07.07.2020

[Kär18a] Kärger, L.; Dörr, D.; Poppe, C.; Seuffert, J.; Bernath, A.; Galkin, S.; Zimmerling, C.; Henning, F.; Continuous Process Simulation for Continuous Fiber Reinforced Composites, International VDI Conference, Amsterdam, 2018.

[Kär18b] Kärger L, Dörr D, Zimmerling C, Seuffert J, Bernath A, Galkin S, Henning F: Composite Design via Continuous Simulation of Process and Structural Behavior - Fundamentals and Applications. AWRT Korea-EU Forum on Automotive Lightweighting, Seoul, 2018.

[Kär20] Kärger L, Galkin S, Dörr D, Poppe C: Capabilities of Macroscopic Forming Simulation for Large-Scale Forming Processes of Dry and Impregnated Textiles, ESAFORM 2020, Cottbus, Procedia Manufacturing 47:140–7, 2020.

[Lbw19] Leichtbau BW GmbH: ThinKing März 2019: Der virtuelle Prozessexperte für den Leichtbau, Web-Information, https://www.leichtbau-bw.de/aktuelles/news/detailansicht/article/thinking-maerz-2019-der-virtuelle-prozessexperte-fuer-den-leichtbau.html , zuletzt aufgerufen am 07.07.2020

[Pfr18] Pfrommer J, Zimmerling C, Liu J, Kärger L, Henning F, Beyerer J: Optimisation of manufacturing process parameters using deep neural networks as surrogate models, Procedia CIRP 72, 2018 pp. 426-431

[Pop17a] Poppe C, Fial J, Kärger L, Carosella S, Zimmerling C, Albrecht F, Draskovic M, Engelfried M, Middendorf P, Henning F: Zeit- und kosteneffiziente Prozess- und Produktentwicklung für den Hochleistungs-Faserverbundleichtbau mittels Nasspresstechnologie. 4. Technologietag Hybrider Leichtbau, Stuttgart, 2017.

[Pop17b] Poppe C. & Zimmerling C., Kärger L., Carosella S., Middendorf P., Henning F.; Zeit- und kosteneffiziente Prozess- und Produktentwicklung für den Hochleistungs-Faserverbundleichtbau mittels Nasspresstechnologie, Marktplatz Leichtbau, Ludwigsburg, 2017.

[Pop18a] Poppe C, Dörr D, Henning F, Kärger, L: A 2D modelling approach for fluid propagation during FE-forming simulation of continuously reinforced composites in wet compression moulding. Submitted for publication in AIP Conference Proceedings, ESAFORM2018, Palermo, 2018.

[Pop18b] Poppe C, Dörr D, Henning F, Kärger L: Experimental and numerical investigation of the shear behavior of infiltrated woven fabrics, Composite Part A, Vol 14, 327-337, 2018.

[Pop19a] Poppe C, Rosenkranz T, Dörr D, Kärger L: Comparative experimental and numerical study on the bending behavior of infiltrated woven fabrics, Composite Part A 124: 105466, 2019.

[Pop19b] Poppe C, Dörr D, Kraus F, Kärger L: Experimental and Numerical Investigation of the Contact Behavior during FE Forming Simulation of Continuously Reinforced Composites in Wet Compression Molding, AIP-Proceedings ESAFORM 2019, Vitoria-Gasteiz, 2019.

[Pop19c] Poppe C, Dörr D, Kärger L: Systematic approach for the development of an FE-based process simulation framework for wet compression moulding of continuously reinforced composites, Proceedings EUROMECH Colloquium 602 – Composite manufacturing processes. Analyses, modelling and simulations, Lyon, France, 2019.

[Pop20a] Poppe C, Albrecht, F, Krauß, C., Kärger, L: A 3D Modelling Approach for Fluid Progression during Process Simulation of Wet Compression Moulding – Motivation & Approach, ESAFORM 2020, Cottbus, Procedia Manufacturing 47:85–92, 2020.

[Pop20b] Poppe C, Krauß, C., Albrecht, F, Kärger L: A fully coupled 3D process simulation approach to predict macroscopic fibre washing of CFRP during wet compression moulding, 15th International Conference on Flow Processes in Composite Materials (FPCM-15), 15-17, 2020, in West Lafayette, IN, USA (Abstract accepted)

[Sch20] Schäfer B, Dörr D, Kärger L: Reduced-Integrated 8-Node Hexahedral Solid-Shell Element for the Macroscopic Forming Simulation of Continuous Fibre-Reinforced Polymers, ESAFORM 2020, Cottbus, Procedia Manufacturing 47:134–9, 2020.

[Wer20a] Werner H, Poppe C, Henning F, Kärger, L: Material Modelling in Forming Simulation of Three-Dimensional Fiber-Metal-Laminates – A Parametric Study, ESAFORM 2020, Cottbus, Procedia Manufacturing 47:154–61, 2020.

[Zim18a] Zimmerling, C.; Pfrommer, J.; Liu, J.; Beyerer, J.; Henning, F.; Kärger, L.: Application and Evaluation of Meta-Model Assiasted Optimisation Strategies for Gripper-Assisted Fabric Draping in Composite Manufacturing, Proceedings of ECCM 2018, Athens, 2018.

[Zim18b] Zimmerling C, Dörr D, Henning F, Kärger, L: A Meta-Model Based Approach for Rapid Formability Estimation of Continuous Fibre Reinforced Components. AIP Conference Proceedings, ESAFORM2018, Palermo, 2018.

[Zim19a] Zimmerling C, Dörr D, Henning H, Kärger L: A Machine Learning Assisted Approach for Textile Formability Assessment and Design Improvement of Composite Components, Composites Part A, 124, 2019, https://doi.org/10.1016/j.compositesa.2019.05.027

[Zim19b] Zimmerling C, Trippe D, Fengler F, Kärger L: An Approach for Rapid Prediction of Textile Draping Results for Variable Composite Component Geometries Using Deep Neural Networks, AIP Conference Proceedings, ESAFORM 2019, Vitoria-Gasteiz, Spain, 2019.

[Zim19c] Zimmerling C, Kärger L, Carosella S, Middendorf P, Henning F: Zeit- und kosteneffiziente Prozess und Produktentwicklung für den Hochleistungs Faserverbundleichtbau unterstützt durch Techniken des Maschinellen Lernens, 6. Technologietag Hybrider Leichtbau, Stuttgart, 2019.

[Zim19d] Zimmerling C, Poppe C, Kärger L: Virtuelle Produktentwicklung mittels Simulationsmethoden und KI, Lightweight Design 06/2019, Springer Fachmedien Wiesbaden, 2019.

[Zim19e] Zimmerling C: Techniken des Maschinenlernens unterstützen Prozessauslegung und Gestaltung von Faserverbundbauteilen, Carbon Composites Magazine 1/2019: 19-20, 2019.

[Zim20a] Zimmerling C, Poppe C, Kärger L: Estimating Optimum Process Parameters in Textile Draping of Variable Part Geometries - A Reinforcement Learning Approach, ESAFORM 2020, Cottbus, Procedia Manufacturing 47:847–54, 2020.

[Zim20b] Zimmerling C, Fengler B, Wen H, Fan Z, Kärger L: Rapid selection of suitable reinforcement type in continuous-fibre-reinforced composites for multiple load cases, ICCS23 & MECHCOMP6, Online-Conference, 2020 (submitted for publication).

IFB

[Dra17] Drašković, M., Pickett, A., Carosella, S., Kärger, L., Henning, F., Middendorf, P., Accelerated residual strength after fatigue testing using in-situ image processing for damage detection, Conference Proceedings SAMPE 2017.

[Dra18] Drašković, M., Pickett, A., Middendorf, P., In-situ image processing of fatigue damaged cross-ply laminates coupled with simulation to predict residual strength degradation. Conference Proceedings ECCM18, Athens, Greece, 2018.

[Eng18] Engelfried, M., Verspohl, I., Mavoungou, L., Middendorf, P., Generating three-dimensional representative volume elements of yarns with statistical distributed fibre orientations, Conference Proceedings FPCM-14, Lulea, Sweden, 2018.

[Eng20] Engelfried, M., Aichele, B., Middendorf, P., Investigation of the friction between dry and wetted carbon filaments, Procedia Manufacturing 47, ESAFORM2020, Cottbus, Germany, 2020.

[Fia18a] Fial J., Carosella S., Wiest P., Middendorf P., A Novel Textile Characterization Approach Using An Embedded Sensor System And Segmented Textile Manipulation, AIP Conference Proceedings, ESAFORM2018, Palermo, 2018.

[Fia18b] Fial J., Hüttl J., Carosella. S, Kärger L., Henning F., Middendorf P., Ganzheitliche Untersuchung der Nasspresstechnologie anhand ausgewählter Prozess- und Simulationsrouten, 5. Technologietag Hybrider Leichtbau, Stuttgart, 2018.

[Fia20a] Fial J., Carosella S., Ring L., Middendorf P., Shear Characterization of Reinforcement Fabrics using printed Strain Sensors, Procedia Manufacturing 47, ESAFORM2020, Cottbus, 2020.

[Fia20b] Fial J., Carosella S., Middendorf P., Forming Characterization of Non-Crimp Fabrics using Textile-applied printed Strain Sensors, Sampe Europe Conference 2020 Amsterdam.