BMWK Optifeed

- Contact:

- Funding:

The project of the research association Forschungskuratorium Textil e.V. is funded via the AiF within the program for supporting the “Industrial Collective Research” (IGF) from funds of the Federal Ministry of Economic Affairs and Climate Protection (BMWK).

- Partner:

KIT-FAST, ITA of RWTH Aachen

- Startdate:

10/21

- Enddate:

09/23

Time-efficient determination of suitable material feeding strategies for stamp-draping processes in fiber-reinforced plastics using machine learning techniques - Optifeed

Reduce costly process trials,

easy usability

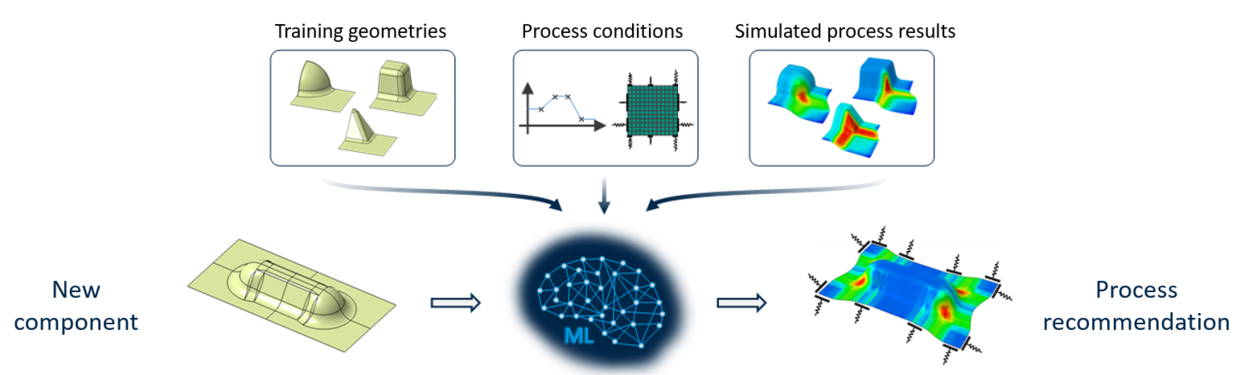

In practice, fine-tuning a manufacturing process for defect-free component production requires numerous cost-intensive process trials. Numerical process simulations in combination with optimisation algorithms can help reduce expensive process trials, but require elaborate material testing, numerical expertise and long computing times. This reduces their attractiveness, especially for SMEs with limited access to powerful computing technology. The search for optimal manufacturing parameters is therefore often experiment- and experience-driven according to expert knowledge.

Better a good early estimate early

than a precise optimisation result late

The increasing availability and user-friendliness of advanced machine learning techniques hints that this expert knowledge can be emulated with 'learning' algorithms. Comparable to an experienced expert, ML-algorithms can learn the relationship between geometry, process conditions and observed component quality from examples. Automated simulations allow to address an enormous range of different process examples to be taken into account and thus the process knowledge of many forming experts to be concentrated in a single algorithm.