Development of macroscopic simulation methods for the deformation of fabrics

Motivation

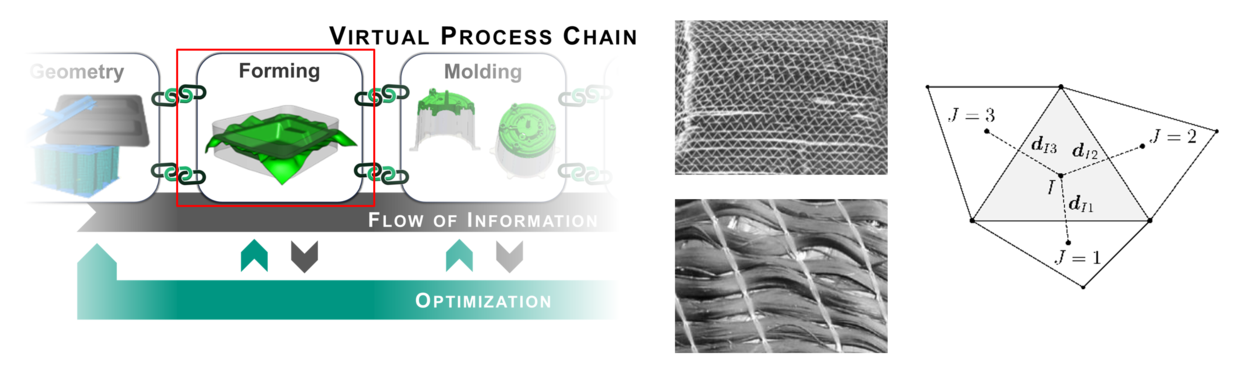

The production of complex-shaped structural components from high-performance composite materials plays a central role in the automotive industry. In the first process step, textile semi-finished products are formed before they are infiltrated with polymers. Continuous fiber-reinforced fabrics made from stitched carbon fibers offer particularly high lightweight construction potential and outstanding mechanical properties.

The forming process is simulated in order to detect and avoid defects such as wrinkling, gaps between fiber bundles or incorrect fiber alignment at an early stage. Macroscopic approaches that consider the fibres as a homogenized material are often used for the efficient modelling of large components. However, local effects, such as the slippage of individual fiber bundles or their bending stiffness, cannot be adequately mapped with these approaches. In order to include these local effects in the simulation, the aim of this project is to extend classic models with so-called neighboring element methods. This makes it possible to provide a reference element with non-local information from its environment.

The task includes the identification and transfer of relevant mesoscopic transformation defects into macroscopic effects, as well as their implementation through the development and extension of Abaqus/Explicit user subroutines. Finally, parameterization studies are used to simulate how the implemented effects affect the forming behavior.

Contents:

- Research on the state of the art and research in the field of macroscopic forming simulation of joints

- Familiarization with forming simulation using the software Abaqus/Explicit software

- Further and new development of Abaqus/Explicit User subroutines to improve the prediction of the forming behavior of fabrics

- Documentation of the work steps and results

Requirements:

- Initiative and independent way of working

- Strong analytical skills

- Interest in simulation and numerics

- Knowledge of working with the simulation software Abaqus/Explicit (advantageous)

- Programming skills in Python and Fortran (advantageous)

Subject area: Mechanical engineering / lightweight construction / computational engineering

Type of work: simulative / numerical

Start: immediately

Application: Please send your CV and transcript of records to the contact email address

Contact: Jan Paul Wank, M.Sc.; Email: janpaul.wank∂kit.edu; Phone: +49 721 608-45904