Vector-Foundation DEmiL

- Contact:

- Funding:

Vector Foundation

- Startdate:

01.03.2017

- Enddate:

31.12.2019

DEmiL (Directly Cooled Electric Motor with Integral Lightweight Housing made of Reactive Injection Molding)

A cooperation project of KIT and Fraunhofer-Institut für Chemische Technologie (ICT)

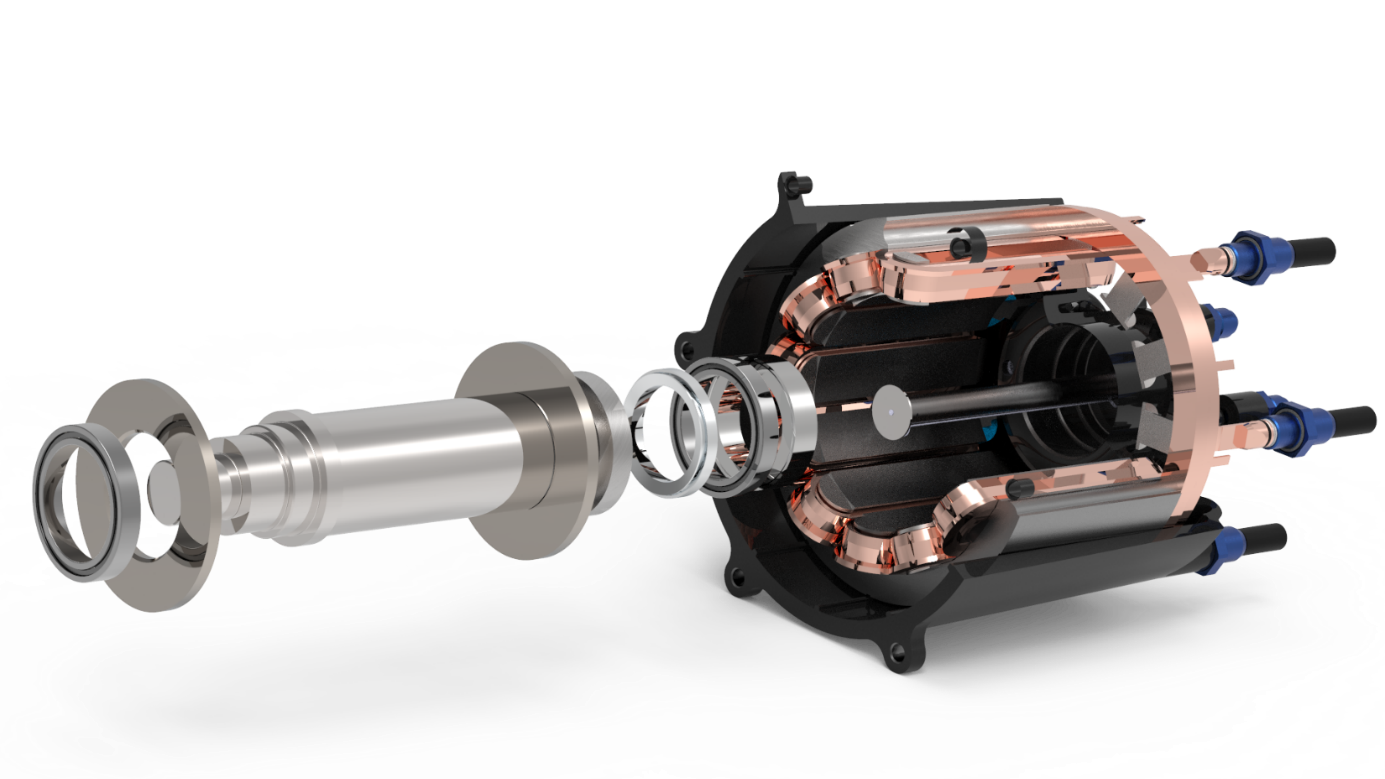

The research focus was on a novel electric motor for traction applications in the e-mobility sector. The permanent-magnet-excited synchronous machine with single-tooth winding is optimized for a high power density and efficiency. The central part of the motor is a stator composed of twelve segmented individual teeth, which are wound up with a flat wire. The rectangular wire is coiled in several layers and thus creates a triangular free space between two neighboring teeth. This free space forms an internal cooling channel for the stator winding and is responsible for the high power density and efficiency of the machine due to the spatial proximity and the resulting optimum heat transfer between the heat source (winding) and the heat sink (cooling medium). Thus, higher continuous loads are possible. Furthermore, the resulting low temperature level within the machine makes it possible to use more inexpensive and high-production process-oriented materials in the region of housing parts. Therefore, the thermoset injection molding process will be in the focus for the overmolding of the stator. The results are published in [1].

Reference:

[1] Langheck A, Reuter S, Saburow O, Maertens R, Wittemann F, Berg LF et al. Evaluation of an Integral Injection Molded Housing for High Power Density Synchronous Machines with Concentrated Single-Tooth Winding. In: 2018 8th International Electric Drives Production Conference (EDPC): IEEE; 2018 - 2018, p. 1–6.