PowerCheckValve

- Contact:

- Funding:

ZIM - Zentrales Innovationsprogramm Mittelstand

Bundesministerium für Wirtschaft und Klimaschutz (BMWK) - Partner:

Müller Landmaschinen GmbH

Motivation

Due to increasing electrification and the associated elimination of the loud noises of the combustion engine, other noises are coming to the fore. These include the noise of pumps and their components. In addition to the noise pollution, it can also be assumed that the vibrations responsible for this have a negative effect on component service life.

Project description

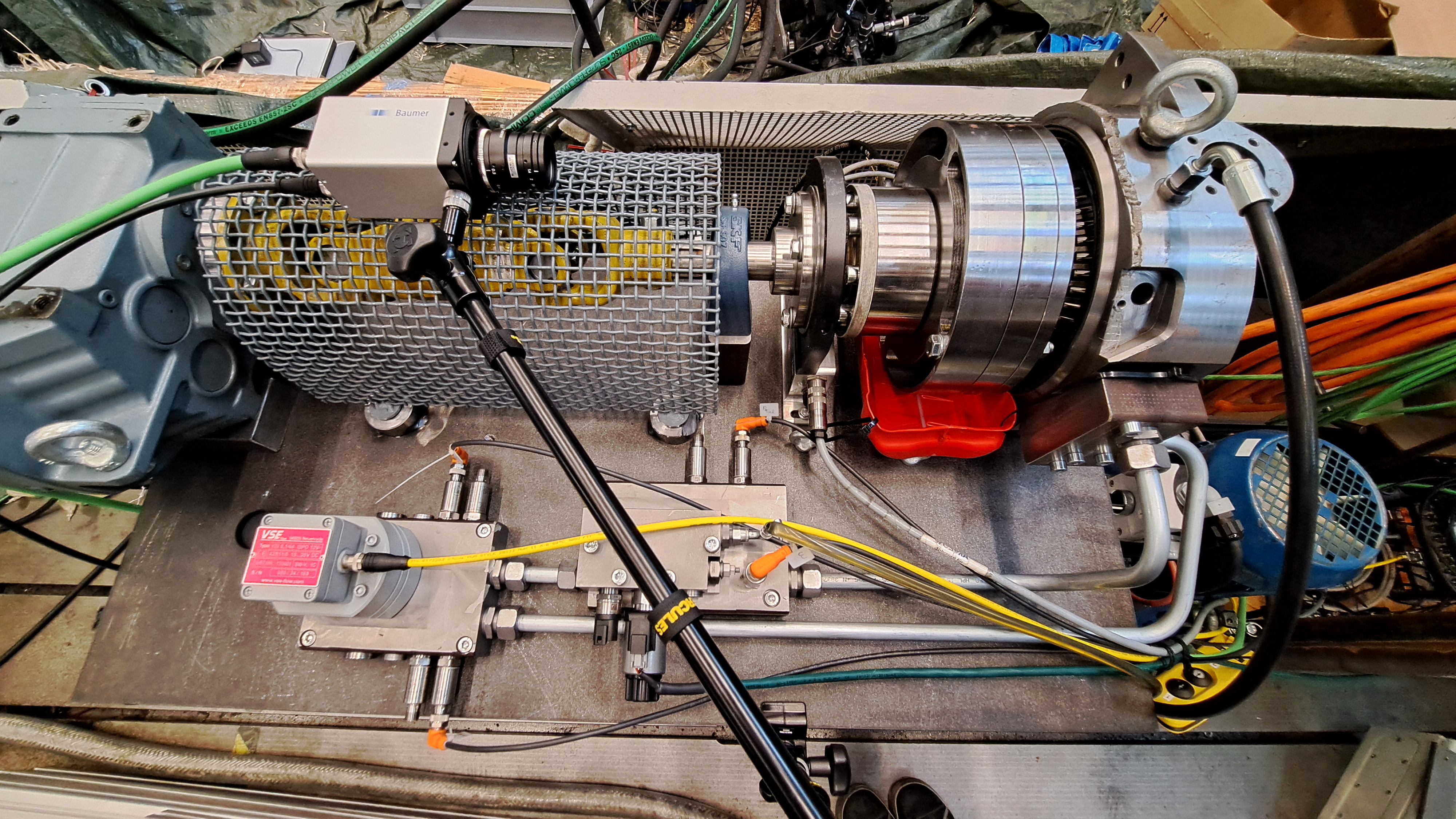

In the project, a radial piston pump integrated in the drive train of a mobile machine is being investigated, in which loud knocking occurs during operation. In this pump, non-return valves are used to separate the piston chamber from the low and high pressure sides. It is assumed that one of these valves is responsible for the knocking. As it is not possible to carry out a precise investigation on the vehicle, a test rig is being set up at the Institute for Mobile Machinery where the pump can be examined in isolation. Here, sensors are used to determine the exact time of the knocking.

Aim

The aim of the project is to find out the exact cause of the knocking. A valve is then to be developed in which the knocking is completely stopped or only occurs at speeds outside the operating range. These results will also be used to create a generally applicable method for developing non-return valves for other high-frequency applications.