7th Colloquium Mobile Hydraulics

On September 27 and 28, 2012, the 7th Colloquium on Mobile Hydraulics took place in and in front of the Audimax at KIT Campus South. The event takes place every two years, alternating between KIT and TU Braunschweig. The special feature is that the speakers exhibit a demonstration object or a demonstration machine alongside their lecture. This allows the theoretical content of the lectures to be demonstrated on a practical object.

The lecture series took place on September 27. After the opening by Professor Geimer, Professor Frerichs and Professor Lang from the Institute for Mobile Machines and Commercial Vehicles at the TU Braunschweig presented current mobile hydraulic activities at research institutions. This was followed by the specialist presentations, which were divided into the topics of "New mechatronic systems", "Hybrid drives and alternative drive concepts" and "Driving and working hydraulics". The main focus was on enhancements to existing functionalities and measures to increase the energy efficiency of mobile machinery.

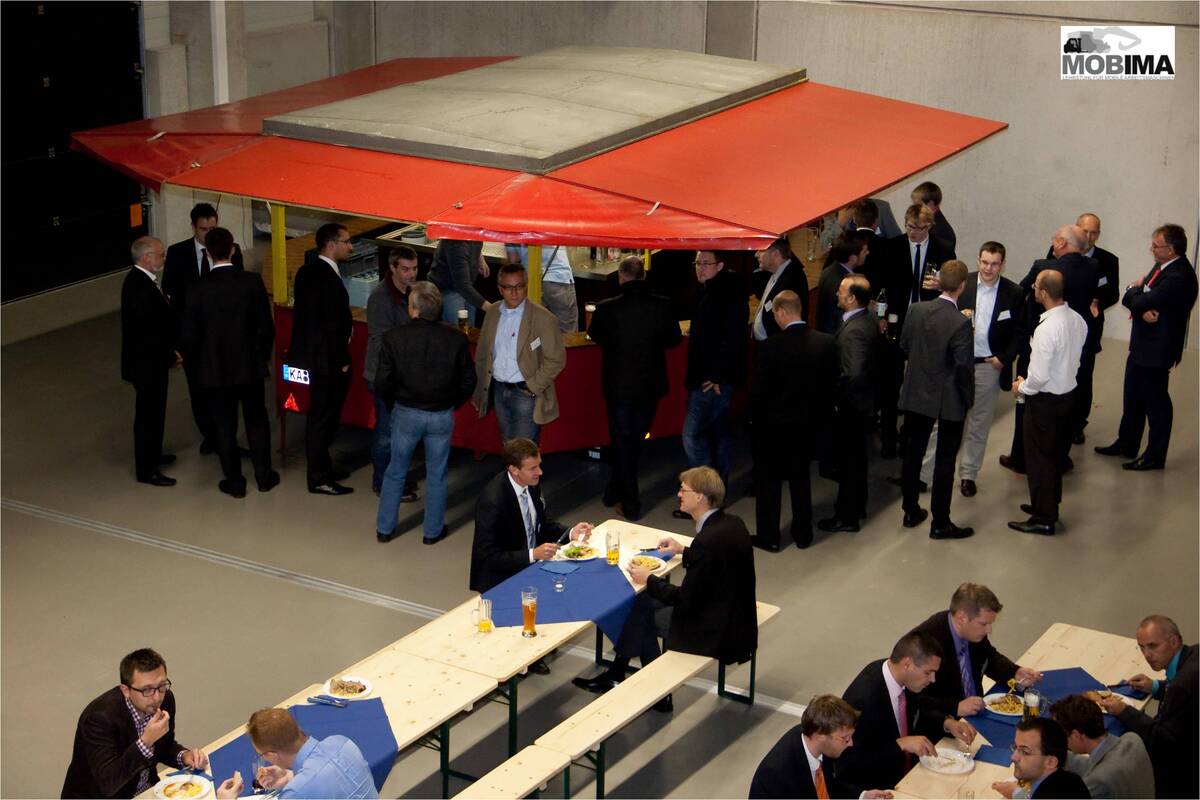

The subsequent evening event took place in the test hall of the Institute of Vehicle Systems Engineering on Campus East. In an informal atmosphere, not only technical topics were discussed over dinner. An exhibition in the test hall and on the new chassis dynamometer framed the evening event.

On the following day, the machine demonstration took place again in the morning in front of the Audimax. The exhibits included a Claas telescopic handler, a Rauch two-disc fertilizer spreader, a wheel loader with parallel kinematic working equipment and a grape harvester from Ero Gerätebau. The event concluded with a lunchtime snack.

The next colloquium on mobile hydraulics is scheduled to take place on October 6/7, 2014 in Braunschweig. October 6/7, 2014 in Braunschweig.

Excursion 2012 - Visiting Liebherr, Hydac, John Deere and Daimler

As part of this year's excursion week, a total of 26 students and employees from the Chair of Mobile Machinery made their way to Colmar, Sulzbach, Zweibrücken and Wörth. The program included visits to the companies Liebherr-France, Hydac, John Deere and the Daimler AG Unimog plant. We received an extremely friendly welcome from the companies and were able to find out all about the company structures, opportunities for internships, final theses and starting a career, as well as a wide range of factory tours. We would like to thank Dr. Späth (Liebeherr), Dr. Bauer (Hydac), Dr. Beck (John Deere) and Dr. Wetzel (Daimler) for their excellent support. All the companies organized a very varied and interesting visit and also took excellent care of our physical well-being.

Special thanks also go to Mr. Mathias Dieter (Hydac), who took the time to join us for dinner. The wide range of information from the management perspective was certainly one of the highlights of this excursion.

Mobima at the Hannover Messe 2012

At the Hannover Messe 2012, the Chair of Mobile Machinery will be presenting the projects Electronic Drawbar for Agricultural Machinery(EDA) and Organic Computing in Off-highway Machines(OCOM) at the KIT stand in Hall 2, Stand C18. These two projects are representative of current research at KIT, and thus demonstrate the interest in agricultural engineering research.

Wheel loader use in teaching

Hands-on teaching examples

On Tuesday, January 17, students on the course "Drive train of mobile machinery" had the special opportunity to experience their theoretical knowledge of hydrostatic travel and work drives on construction machinery live using two practical examples. Two wheel loaders from the Liebherr Group were used to explain and practically demonstrate the relevant systems and assemblies. In addition to the chair's own L509 Stereo wheel loader with an operating weight of approx. 6 tons and a 1.1 m³ bucket, a Liebherr L586 2plus2 was also available. This large wheel loader with an operating weight of around 32 tons and a bucket capacity of 5.5 m³ has a 250 KW diesel engine and the hydrostatic "2plus2" drive, which was previously explained in theory in the associated course. The wheel loader was provided by the Liebherr Group for the acceptance test of the new all-wheel acoustic roller test bench at Campus East. The students had the opportunity to examine the machines in detail and ask questions. Several practical demonstrations of driving, working and steering hydraulics concluded the event.

The course "Drive train of mobile machinery" deals with the topic of drive technology from the perspective of mobile machinery. In contrast to the widely known technologies from the automotive sector, the wide range of prevailing drive types in the work machinery sector is explained here. These include various types of (load) shift, continuously variable and power split transmissions, which are realized by means of mechanical, electrical, hydrostatic or hydrodynamic components. Other components such as axles and tires and related assemblies such as steering and working hydraulics round off the range of topics.