Research Focuses

Lighter vehicle structures enable more environmentally friendly mobility. The weight of load-bearing components can be significantly reduced by using high-performance fiber-reinforced composites (HPFRPs). However, load-bearing FRP components can only be designed with optimized weight if the anisotropy of the fibers is fully exploited and if the influences of manufacturing on material behavior are correctly identified and taken into account. To increase the simulability of HL-FRP, YIG is dedicated to the following research topics:

-

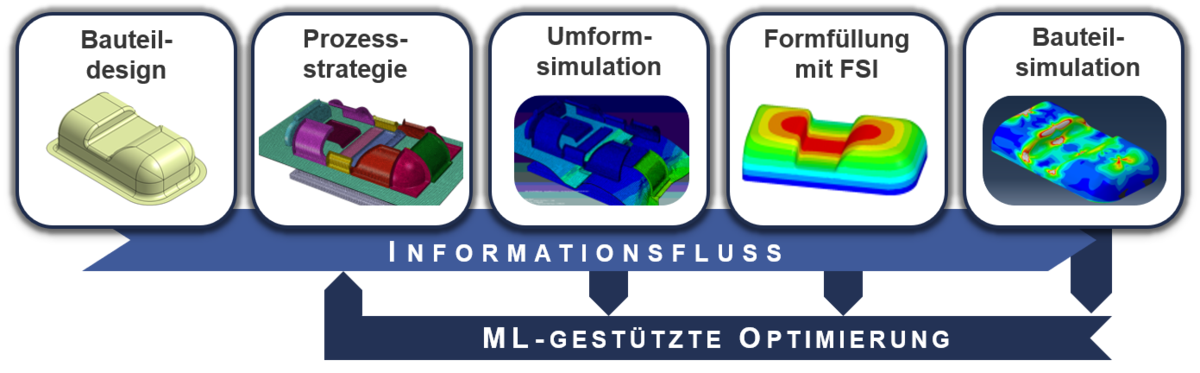

Development of end-to-end CAE chains. In the course of the global trend of digitalization, end-to-end CAE chains and digital twins are a clear competitive advantage in product development. The challenge lies primarily in the combination of efficient overall product consideration (for industrial applicability) and necessary detail modeling.

-

Forming simulation of semi-finished fiber products. YIG has achieved international visibility with its forming simulation methods. Current research topics concern the macroscopic detection of mesoscopic effects of fiber layups, the forming and compacting behavior of thick semi-finished products and the forming behavior under simultaneous infiltration in wet pressing processes.

-

Mold filling processes with fiber-matrix interaction and hybridization. Process-inherent interactions between fibers and matrix flow are a challenge for simulation. YIG is at the forefront of simulating the wet pressing process, mold filling of sandwich structures with fluid-structure interaction, and cross-scale simulation of RTM, injection molding, and impact extrusion processes. Current research topics additionally concern the simulation of additive manufacturing processes as well as the simulation of hybrid processes, with a special focus on warpage and residual stresses.

-

Structural simulation of fiber composite components. In structure simulation, YIG's research focus is on the influence of manufacturing effects. Multiscale simulations are performed to investigate the influence of fiber structure on rate-dependent material behavior. In DFG-SPP 1897, models for hybrid composite-elastomer-metal laminates are developed, including higher order shell formulations.

-

Process and structural optimization for lightweight products. In addition to taking manufacturing effects into account, the CAE chain enables optimization over several simulation steps. However, highly accurate simulation methods are generally too costly for product optimization. AI methods, physics-based approximation methods or a combination of both (black-, white-, grey-box models) can be used to increase efficiency. In the YIG, surrogate-based optimization approaches (SBO) for forming processes and methods for rapid process evaluation are developed.

Support of the YIG by the Vector Foundation

We would like to express our sincere thanks to the Vector Foundation for supporting the Young Investigator Group. The foundation was established in 2011 by the founders of Vector Informatik GmbH, Eberhard Hinderer, Martin Litschel and Dr. Helmut Schelling. The foundation's purposes are the sustainability of research as well as social commitment. Talent is supported through the promotion of young scientists, scholarships, research projects and endowed professorships. A focus is placed on the topic of environmentally friendly and sustainable mobility.

Under the guiding principle of "Green Mobility", Prof. Dr.-Ing. Luise Kärger was awarded funding by the Vector Foundation for the research topic "Weight-optimized vehicle structures using tailored high-performance fiber composites".

Prof. Dr.-Ing. Kärger has been head of the junior research group "Green Mobility" at the Chair of Lightweight Construction Technology from July 1, 2014. After the YIG "Hybrid Lightweight Construction" of PD Dr.-Ing Kay Weidenmann, which was funded by the Excellence Initiative in the years 2007-2011, a second junior research group was thus dedicated to the research field of lightweight construction.

Our thanks also go to the KIT Foundation, which provides us with the funds from the Vector Foundation donations and whose fundraising activities made the YIG possible in the first place.