Peak Compensator - Active neutralization of externally induced load peaks on the drivetrain

- Contact:

- Funding:

ZIM - Central Innovation Program for Small and Medium-Sized Enterprises,

Federal Ministry for Economic Affairs and Energy - Partner:

- Startdate:

01.08.2018

- Enddate:

31.07.2020

Motivation:

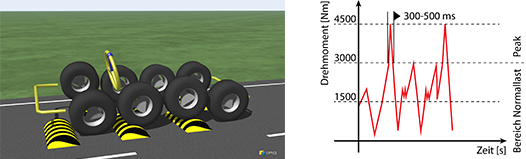

Vehicle drivetrains are subjected to load peaks well in excess of their rated load. In order to prevent premature failure of the components in the power flow, they must be sufficiently dimensioned to withstand the peak loads. As it is very difficult to determine the loads on the components due to peaks in tests, the proof of strength in the state of the art is mainly based on empirical and safety values. The higher dimensioning and usually conservative choice of safety coefficients results in an increased mass in the traction drive. This leads to additional production costs and increased inertia of the drivetrain, which has a negative impact on driving dynamics, fuel consumption and emissions.

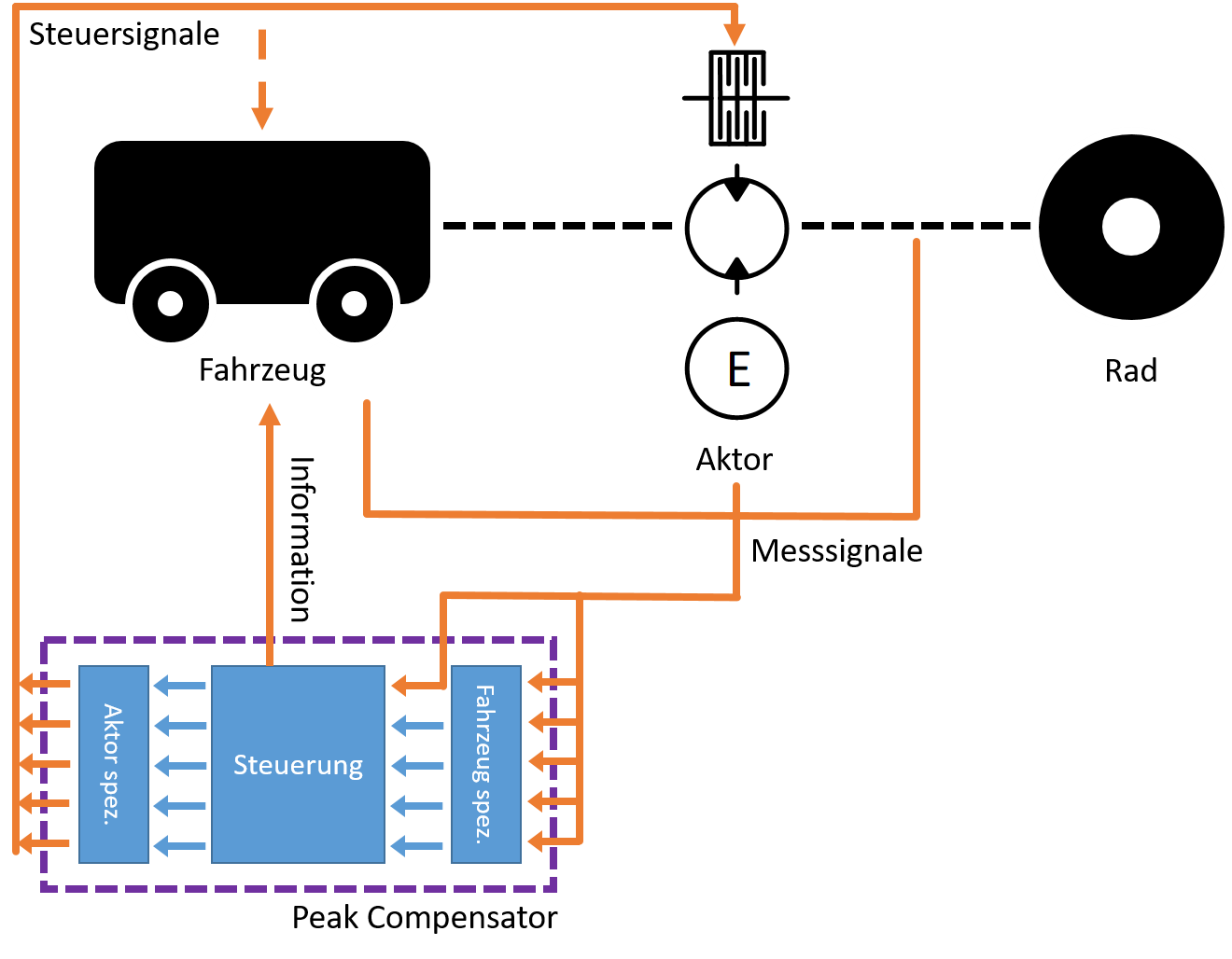

The aim of the project is to detect torque peaks, distinguish them from normal torque requirements and initiate elimination close to the wheel using suitable actuators before the peaks are passed through the drivetrain.

Functionality and design:

In order for peaks to be neutralized, they must first be detected using suitable sensors and driving status data. Once a peak has been detected, an action strategy can be derived by the control system. Depending on the vehicle and its driving status, a target status must be determined for each wheel. The target state is then adjusted via an interface between the controller and actuator. Detection, processing and control are time-critical. All steps must be carried out quickly enough so that the actuators can neutralize the peak in good time. Frequencies from 2 Hz to 20 Hz, due to bumpers on the road, are the focus of the investigation. In addition, the system must be safe in every application and vehicle condition. When driving uphill, the control system should neutralize detected peaks so that the vehicle does not lose momentum and comes to a standstill. In particular, driving through steep ramps, as is often the case when driving off-road, poses a major challenge.

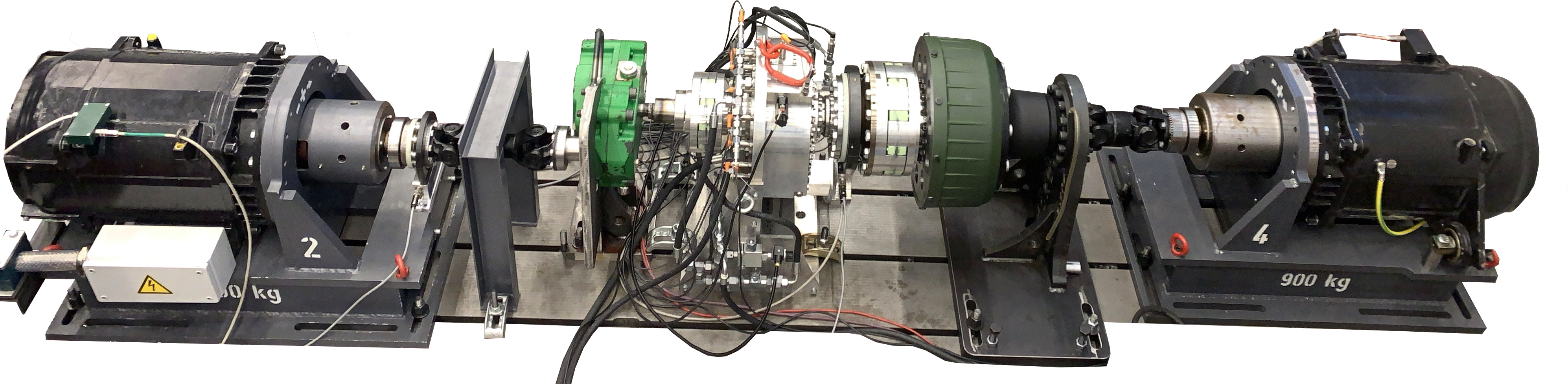

challenge here. An XiL approach is used to investigate different strategies in different driving situations as early as possible. This involves simulating a vehicle and driving situation, the control system of which controls a real actuator on the test bench. The actuator is clamped between two electric motors, which are controlled by the simulation to generate realistic operating conditions for the actuator.

Publications

-

Auflösung von geländeseitig verursachten Antriebsverspannungen bei hochmobilen Arbeitsmaschinen

Herr, S.; Müller, W.; Müller, J.; Eckloff, U.

2020. 11. Kolloquium Mobilhydraulik, Karlsruhe, 10. September 2020. Hrsg.: M. Geimer, 43–54, KIT Scientific Publishing