Scientific Support from Idea to Innovation: Line Traction 3 (LT3)

- Contact:

- Funding:

ZIM - Central Innovation Program for Small and Medium-Sized Enterprises, Federal Ministry for Economic Affairs and Energy

- Partner:

A technology emerges – from practice to research

The “Line Traction 3” (LT3) drive technology is an outstanding example of successful cooperation between industry and science. The idea and the patent originate from Werner Müller, owner of Müller Landmaschinen GmbH in Bonndorf. With the aim of fundamentally improving the drive technology of mobile machines, Mr. Müller approached our institute more than ten years ago – with a vision that we have been intensively supporting scientifically ever since.

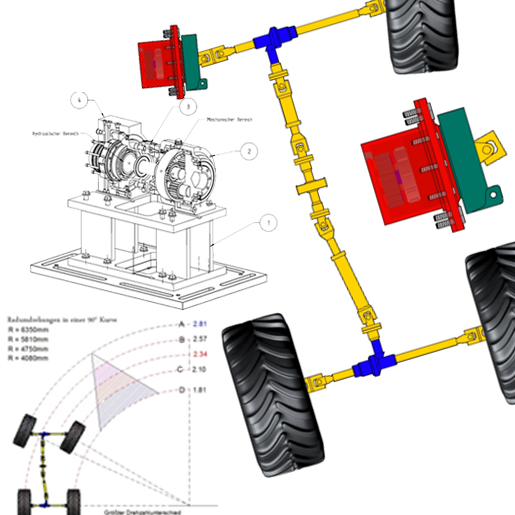

The idea

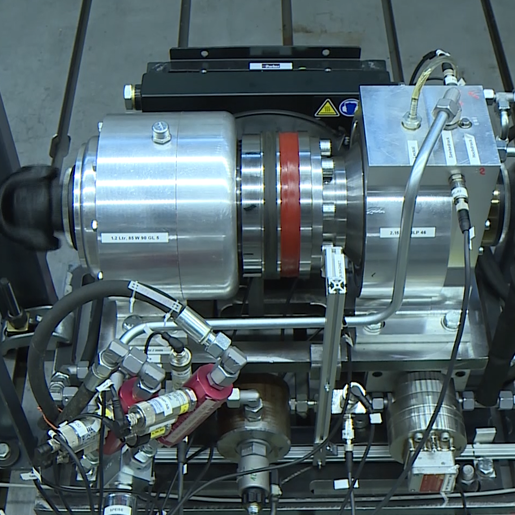

At the heart of the system is a hydraulically controlled superimposed gearbox that replaces conventional differentials and enables individual control of torque and speed for each wheel. This allows the system to deliver optimum power to the ground with any central drive, regardless of its drive technology (combustion engine, battery-electric drive, etc.). Advantages for users include a wider range of applications for the machine, greater safety thanks to improved directional stability and increased traction, and significantly reduced operator workload thanks to the automated drive train.

From idea to innovation

In a research process spanning several years, LT3 technology was scientifically monitored from the theoretical idea through simulations and trials with prototypes to pre-series production readiness. The research work was supported by our high-performance infrastructure, including a specially equipped drive system test bench and a 4WD-Acoustic-Chassis-Dynometer, which allow realistic trials under variable operating conditions. The results of this research and development are now being incorporated into a product for the first time thanks to the cooperation between Müller Landmaschinen GmbH and vehicle manufacturer Aebi Schmidt. Scientific methods and expert knowledge, as well as the close integration of theory and practice, have turned this idea into an innovation.

Research projects related to LT3

During the scientific support, new, previously unanswered questions arose repeatedly, giving rise to several independent research projects:

Research meets industry

LT3 technology is now being brought to market by Müller Landmaschinen in collaboration with Aebi Maschinenfabrik & Co. AG. The close integration of university research and industrial development - supported by the Federal Ministry for Economic Affairs and Energy - has produced a pioneering drive solution that has the potential to bring about lasting change in the market for mobile machinery.

Winner of the 2025 AGRITECHNICA Innovation Award in Gold

LT3 technology was selected from numerous international entries to receive the 2025 AGRITECHNICA Innovation Award in Gold – one of the most prestigious awards in the agricultural industry. The award recognizes practical technical innovations and underscores the importance of modern agricultural technology for the future of agriculture. The decision was made by an independent commission of experts from the DLG after intensive examination and discussion.

You can find out more about the technology and its possible applications at AGRITECHNICA 2025 in Hall 02 at Stand 02F38.

More information about the system from Müller Landmaschinen GmbH.

Publications

-

Verbesserungspotentiale in der Fahraufgabe durch variable Raddrehmomente am Beispiel mobiler Arbeitsmaschinen. Dissertation

Engelmann, D.

2025, Juli 7. Karlsruher Institut für Technologie (KIT). doi:10.5445/IR/1000182815 -

Auflösung von geländeseitig verursachten Antriebsverspannungen bei hochmobilen Arbeitsmaschinen

Herr, S.; Müller, W.; Müller, J.; Eckloff, U.

2020. 11. Kolloquium Mobilhydraulik, Karlsruhe, 10. September 2020. Hrsg.: M. Geimer, 43–54, KIT Scientific Publishing -

Validierung neuer Funktionen eines mechanischen Antriebsstrangs für mobile Arbeitsmaschinen mit radindividueller Steuerung

Engelmann, D.; Herr, S.

2018. International VDI Congress Dritev - Drivetrain for vehicles, EDrive, Transmissions in mobile machines, Bonn, Germany, June 27 - 28, 2018, 81–82, VDI Verlag -

Validierung eines mechanischen Antriebsstrangs mit radindividueller Steuerung

Engelmann, D.; Herr, S.

2018. ATZ offhighway, 11 (1), 8–15. doi:10.1007/s35746-018-0001-7 -

Validation of a Mechanical Drive with Individual Wheel Control

Engelmann, D.; Herr, S.

2018. ATZ offhighway, 11 (1), 8–15. doi:10.1007/s41321-018-0001-7 -

Testing and Benchmarking a Powertrain with Independent Wheel Control for Heavy Machinery

Engelmann, D.; Unger, M. R.; Geimer, M.

2017. VDI-MEG Conference: Agricultural Engineering - Land.Technik AgEng 2017, Hannover, Germany, November 10-11, 2017, 303–313, VDI Verlag -

LT3 Drive: substitution of differentials in the drivetrain

Eckloff, U.; Engelmann, D.; Müller, W.

2017. EVS30 International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, Stuttgart, Germany, October 9 - 11, 2017 -

MOBiL – Eine auf mobile Arbeitsmaschinen optimierte Prüfmethode

Brinkschulte, L.; Engelmann, D.; Siebert, J.; Geimer, M.

2017. Hybride und energieeffiziente Antriebe für mobile Arbeitsmaschinen : 6. Fachtagung, 15. Februar 2017, Karlsruhe, 173–194, KIT Scientific Publishing -

Project “Line Traction 3” - Mechanical driveline with active wheel hubs

Engelmann, D.; Müller, W.; Geimer, M.

2016. Drivetrain for vehicles 2016: 4th International VDI Conference Transmissions in Mobile Machines : Friedrichshafen, June 21 and 22, 2016, 731–742, Düsseldorf -

Anforderungen an das Antriebssystem eines schweren NFZ

Engelmann, D.; Geimer, M.; Müller, J.; Müller, W.

2015. ATZoffhighway, 8 (2), 26–37. doi:10.1007/s35746-015-0017-1