Test bench for investigating innovative electric, hybrid-electric and conventional drive train topologies for mobile machinery

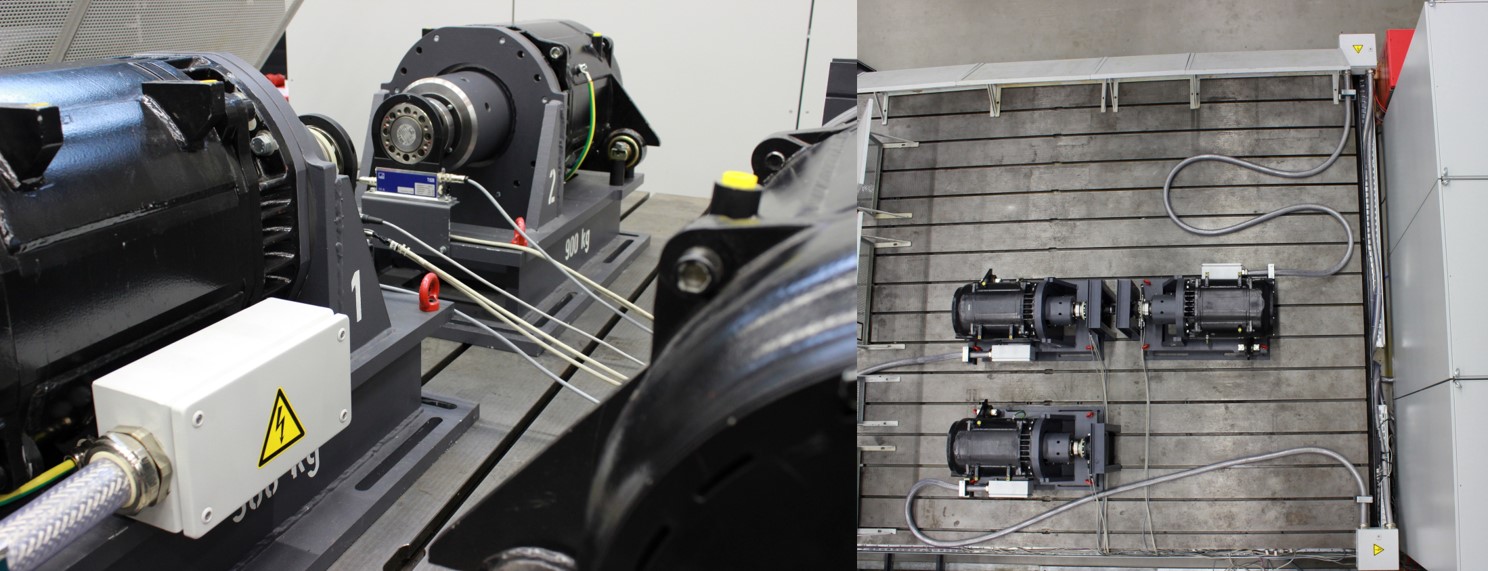

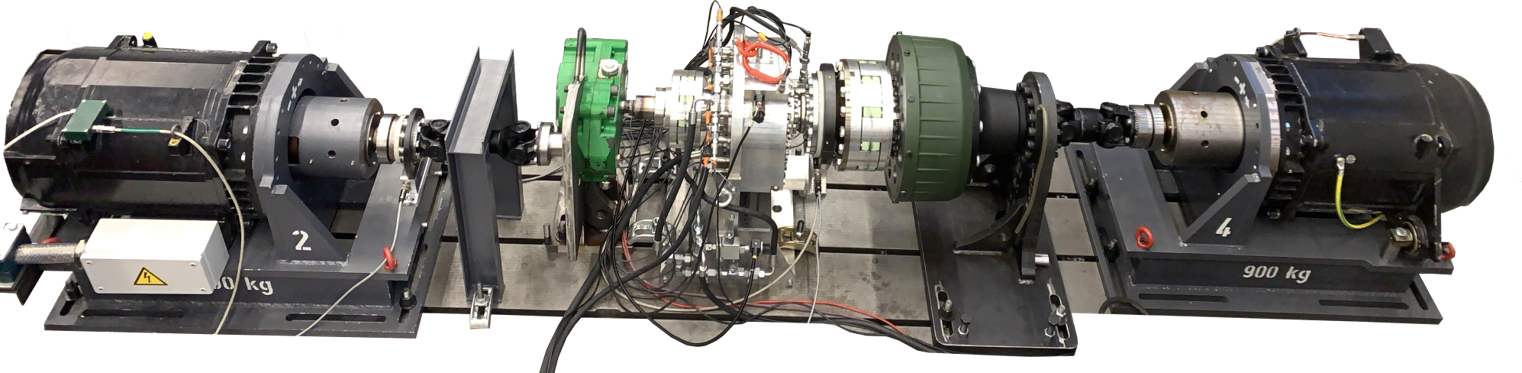

The driveline test bench is used to examine and analyse electric, hybrid-electric and conventional drivelines and driveline components. The modular design of the test bench enables the realisation of individual test setups. Four freely configurable drive and load machines enable experiments with individual drivetrain components, complex subsystems and even the entire drivetrain of a wide range of vehicles.

The four electric machines can be controlled manually, analogue or via a digital CAN interface. The test bench includes a comprehensive measurement system for recording and analysing the test bench and test specimen data. An automation system is used to realise dynamic load profiles and for holistic testing of components and drivetrains using the ‘hardware in the loop’ approach. For example, the test bench can be coupled with IPG CarMaker via a real-time computer in order to analyse a system within a driving simulation. The test bench can also be used in combination with the central pressure supply to drive pumps or simulate rotating loads, for example.

The hall infrastructure offers options for water cooling, pressurisation of hydraulic components and the integration of additional drives. Possible examples include additional electric motors, combustion engines and charging infrastructure/supply for electric storage systems and drives.

Request:

mobima∂kit.edu

Application examples

- Customised investigation of drive components/systems

- Performance and efficiency measurements

-

Load simulation for rotary drives

-

Investigation of systems coupled with (driving) simulations, e.g. MATLAB/Simulink, IPG CarMaker/TruckMaker

-

Combined analysis of electric and hydraulic drivese

-

Pump tests

-

Drive of independent hydraulic superstructures

Measurement technology

-

Hydraulic pressure (400 bar) und volume flow rate(400 l/min)

-

Rotational speeds up to 8000/20000 1/min and torque up to 1000 Nm/15000 Nm

-

Precision power meter: Voltage up to 1000 V and current up to 400 A

-

data bus recording: CAN, J1939, Isobus, Ethernet

-

Universal connection of further analogue and digital measured variables

Technical data

|

260 kW |

|

|

4 identical e-motors (4Q-inverter at DC-intermediate circuit) |

|

|

130 kW |

|

|

700 Nm |

|

|

1780 1/min |

|

|

1000 Nm |

|

|

5500 U/min |

|

|

4 m x 5 m |