Hydraulic system for supplying system and component test benches with up to 800 l/min and 320 bar.

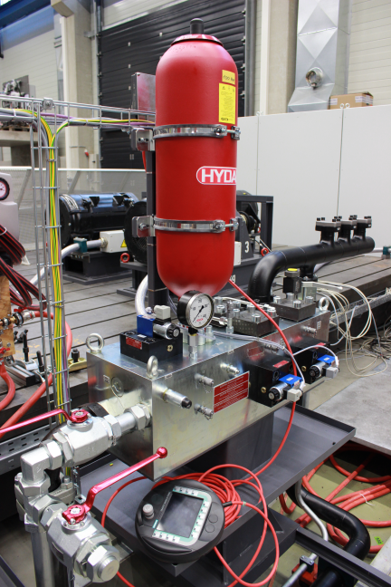

Since 2014, Mobima has had a central pressure supply with an electrical connected load of 360 kW, which is currently designed as a system with impressed pressure. The system supplies 4 tapping points that can be used in parallel, one of which supplies the hydraulic drives of the large internal drum test bench GRIPS. In combination with the existing test bench infrastructure, tests can be carried out with both purely hydraulic and combined hydraulic-electric power input and output. The implementation of the system enables a wide variety of different test scenarios: From pure component testing to the simulation and validation of complex systems, such as the hydrostatic drive train of a mobile work machine.

The central pressure supply is currently being used to supply a LoadSensing (LS) drivetrain with three consumers, among other things. Thanks to extensive measurement technology, such systems can be analyzed precisely. Thus, a validated LS simulation model could be derived, with the help of which a new possibility for reducing pressure losses in LS systems was developed.

In this way, it is possible to first examine new architectures in the simulation and then implement and validate them on the hydraulic test bench. Furthermore, other test setups can be set up alongside the existing LS system so that direct comparisons are possible.

Request:

mobima∂kit.edu

Application examples

-

Investigation of complex hydraulic systems, e.g. LS system

-

Analysis of hydraulic components and their function

-

Investigation of control strategies

-

Energy efficiency, energy recovery: recuperation/regeneration

-

Pump investigations

-

Supply of drive units, closed and open hydraulic circuits

-

Combined analysis of electric and hydraulic drives

Measurement technology

-

Hydraulic pressures (400 bar) and volume flows (400 l/min)

-

Speeds and torques up to 1000 Nm/15000 Nm

-

Forces (up to 125 kN available)

-

Data bus recording: CAN, J1939, Isobus, Ethernet

-

Universal connection of further analog and digital measured variables

Technical data

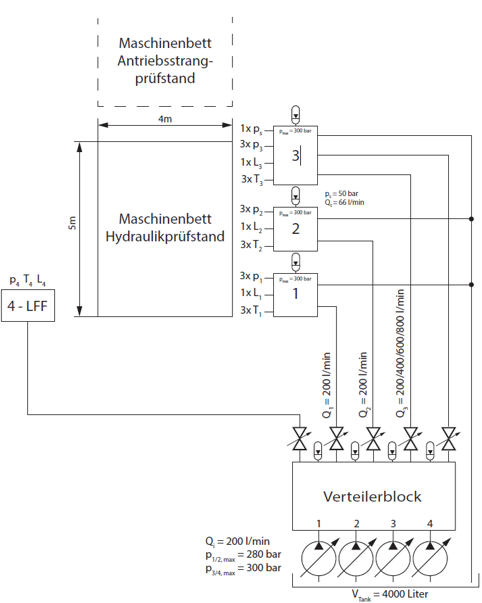

Connected load | 4x 90 kW (360 kW in total) |

Maximum pressure | 280 (4061 psi)/320 bar (4351 psi) |

Maximum volume flow | Σ 800 l/min (211 gpm) |

Tank volume | 4000 l |

Oil used | HLP-46 |

Hydraulic pumps | 4 axial piston machines, 200 l/min each 1 vane pump as feed pump |

Feed circuit | 66 l/min (14.7 gpm) 50 bar (725 psi) |

Machine bed | 2 pieces each 4 m x 5 m |

Tapping points | Tapping points 1 & 2 0 ... 200 l/min (52.8 gpm) Tapping point 3 & 4 0 ... 800 l/min (211 gpm) Tapping point 4 permanently supplies the GRIPS test stand. |